Extreme pressure stamping oil and preparation method thereof

A stamping oil and extreme pressure technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of poor extreme pressure of stamping oil and poor industrial use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

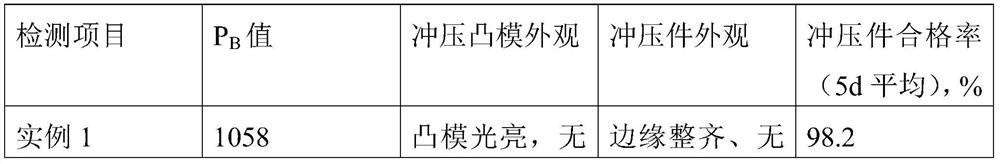

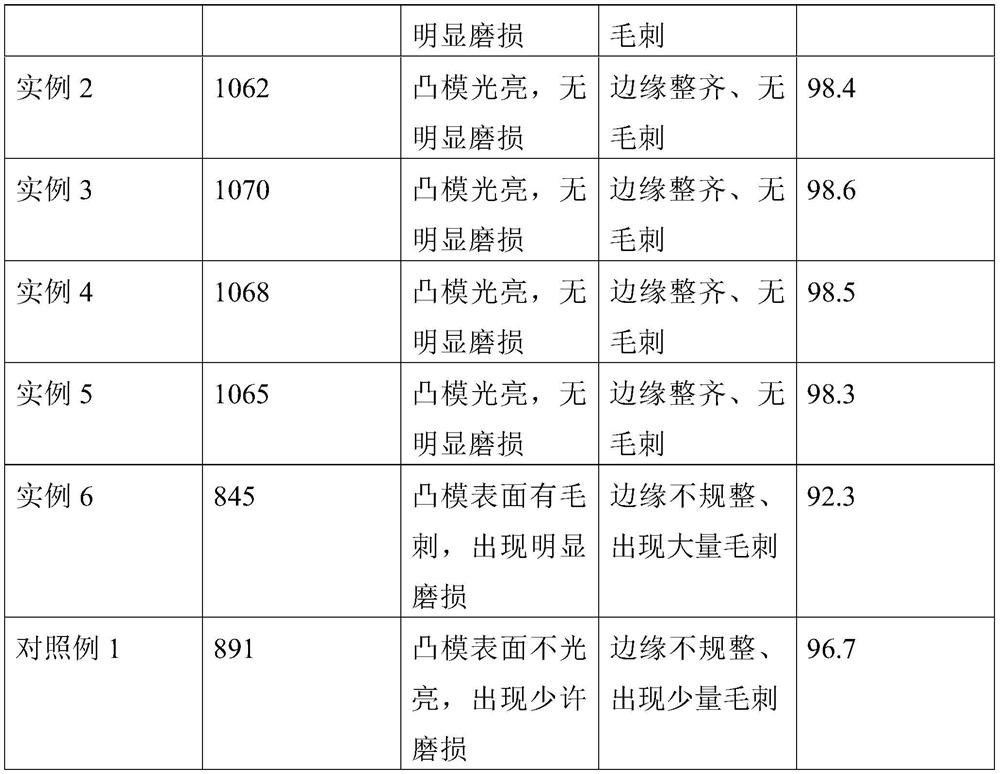

Examples

example 1

[0046] Mix the nano-aluminum powder and the sodium hydroxide solution with a mass fraction of 30% according to the volume ratio of 1:10, mix and shake for 20 minutes, then filter and separate to obtain the filter residue, rinse with deionized water repeatedly for 10 minutes, and then put in dopamine with a concentration of 0.5mg / L solution, stirred and reacted for 3 hours, then filtered, separated to obtain a filter cake, which is modified aluminum powder; according to the mass ratio of 1:2, put soybean shells and pigeon manure into a tissue grinder and pulverize for 2 hours to obtain a mixed pulverized product, which was mixed Put the pulverized material in a greenhouse with a temperature of 45°C and a relative air humidity of 70%, and let it stand for moldy treatment for 5 days to obtain a moldy mixture; mix the moldy mixture with water at a mass ratio of 1:5 and transfer it to a fermenter. Seal the mouth of the tank, seal and ferment at 35°C for 10 days, filter the fermentat...

example 2

[0048] Mix the nano-aluminum powder and the sodium hydroxide solution with a mass fraction of 30% according to the volume ratio of 1:10, mix and shake for 20 minutes, then filter and separate to obtain the filter residue, rinse with deionized water repeatedly for 10 minutes, and then put in dopamine with a concentration of 0.5mg / L solution, stirred and reacted for 3 hours, then filtered, separated to obtain a filter cake, which is modified aluminum powder; according to the mass ratio of 1:2, put soybean shells and pigeon manure into a tissue grinder and pulverize for 2 hours to obtain a mixed pulverized product, which was mixed Put the pulverized material in a greenhouse with a temperature of 45°C and a relative air humidity of 70%, and let it stand for moldy treatment for 5 days to obtain a moldy mixture; mix the moldy mixture with water at a mass ratio of 1:5 and transfer it to a fermenter. Seal the mouth of the tank, seal and ferment at 35°C for 10 days, filter the fermentat...

example 3

[0050] Mix the nano-aluminum powder and the sodium hydroxide solution with a mass fraction of 30% according to the volume ratio of 1:10, mix and shake for 20 minutes, then filter and separate to obtain the filter residue, rinse with deionized water repeatedly for 10 minutes, and then put in dopamine with a concentration of 0.5mg / L solution, stirred and reacted for 3 hours, then filtered, separated to obtain a filter cake, which is modified aluminum powder; according to the mass ratio of 1:2, put soybean shells and pigeon manure into a tissue grinder and pulverize for 2 hours to obtain a mixed pulverized product, which was mixed Put the pulverized material in a greenhouse with a temperature of 45°C and a relative air humidity of 70%, and let it stand for moldy treatment for 5 days to obtain a moldy mixture; mix the moldy mixture with water at a mass ratio of 1:5 and transfer it to a fermenter. Seal the mouth of the tank, seal and ferment at 35°C for 10 days, filter the fermentat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com