Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of high transmission resistance of ZnO thin films, unstable perovskite thin films, low density of thin films, etc. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] On the other hand, based on the above-mentioned perovskite solar cell, the embodiment of the present invention also provides a preparation method of the above-mentioned perovskite solar cell. The preparation method of the perovskite solar cell comprises the following steps:

[0021] Form a film on a conductive substrate with ZnO nano-sol containing zinc acetylacetonate, and then anneal at a temperature not higher than 150°C.

[0022] Wherein, in one embodiment, the ZnO nano-sol is prepared according to the following method: dispersing ZnO nanoparticles and zinc acetylacetonate in a liquid medium. In this way, the ZnO nanoparticles and zinc acetylacetonate can be uniformly dispersed in the sol. In a further embodiment, the concentration of the ZnO nanoparticles in the ZnO nanosol is controlled to be 1-20 mg / mL. In another embodiment, the molar ratio of the zinc acetylacetonate to the ZnO is 1:(5˜1000). Like this, by controlling the content and the concentration thereo...

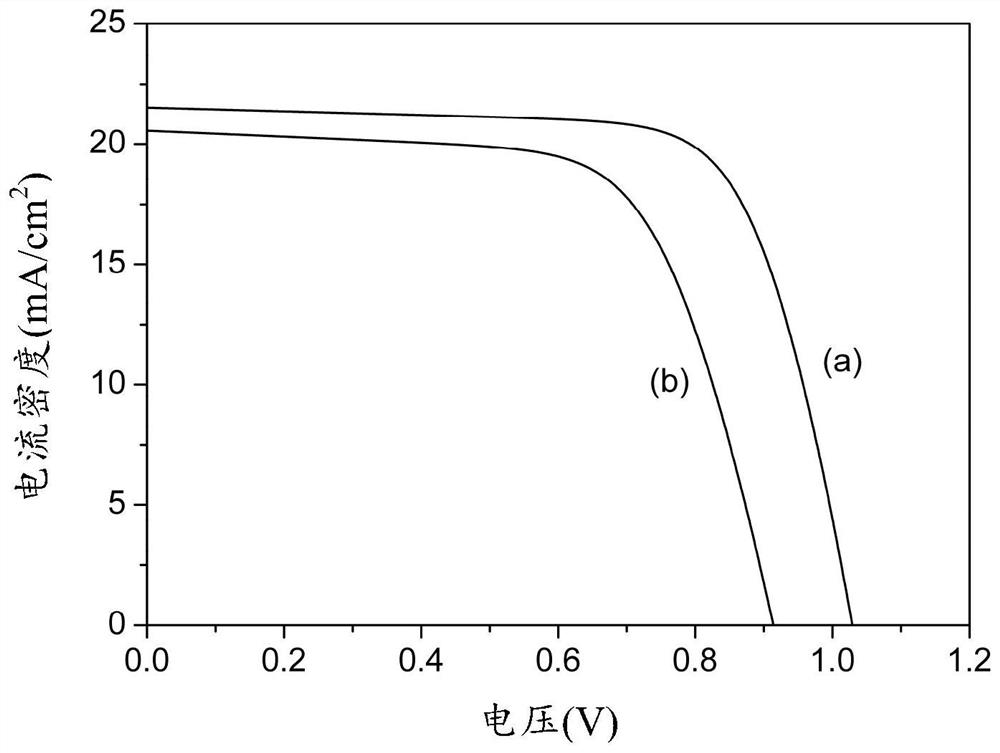

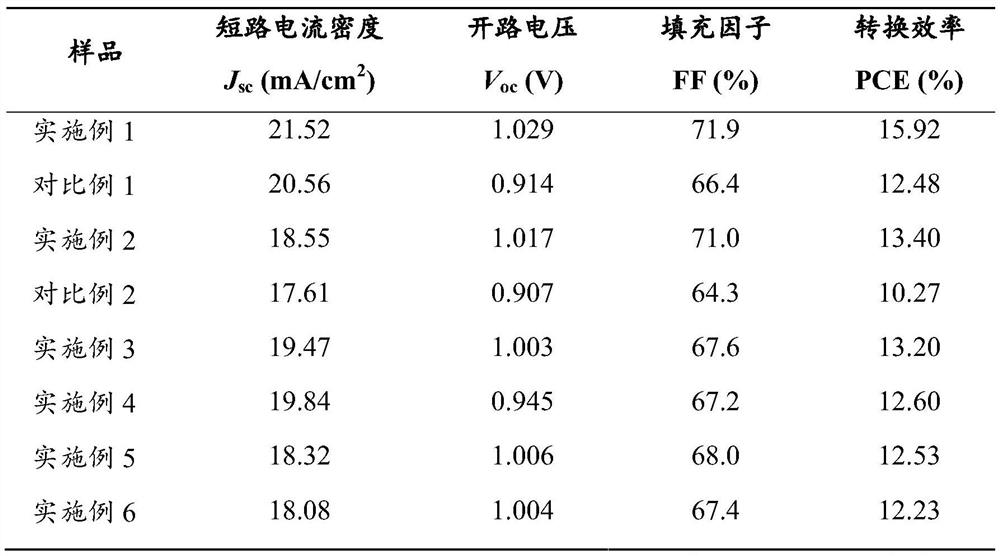

Embodiment 1

[0030] This embodiment provides a perovskite solar cell and a preparation method thereof. The perovskite solar cell in this embodiment includes a conductive substrate and an electron transport layer stacked and bonded on the surface of the conductive substrate, wherein the electron transport layer is formed by annealing at 150°C with a film layer containing ZnO nanoparticles and zinc acetylacetonate . The thickness of the electron transport layer is about 30nm, and the molar ratio between zinc acetylacetonate and ZnO contained in the electron transport layer is 1:10.

[0031] The preparation method of the perovskite solar cell of the present embodiment comprises the following steps:

[0032] S11. Preparation of ZnO nano-sol: Weigh 2.195g of zinc acetate dihydrate and add it to 100mL of methanol, stir and dissolve at 60°C, and dissolve 50mL of potassium hydroxide with a concentration of 0.35mol / L at 60°C under continuous stirring The methanol solution was added dropwise to th...

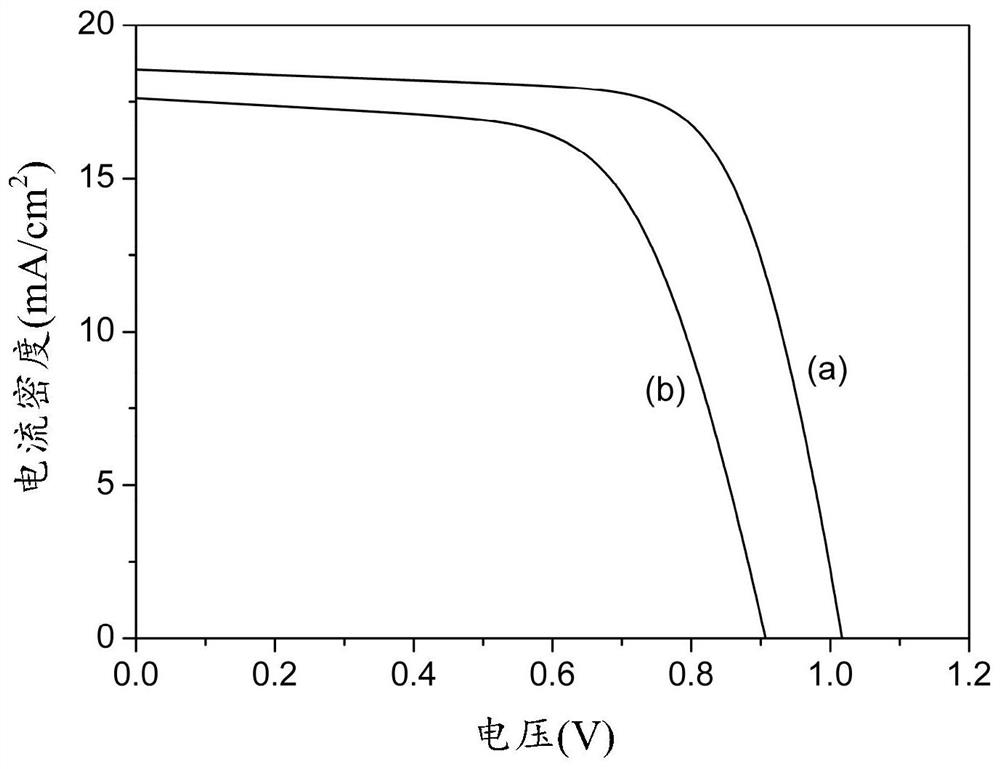

Embodiment 2

[0046] This embodiment provides a perovskite solar cell and a preparation method thereof. The perovskite solar cell in this embodiment includes a conductive substrate and an electron transport layer stacked and bonded on the surface of the conductive substrate, wherein the electron transport layer is formed by annealing at 150°C with a film layer containing ZnO nanoparticles and zinc acetylacetonate . The thickness of the electron transport layer is about 30nm, and the molar ratio between zinc acetylacetonate and ZnO contained in the electron transport layer is 1:10.

[0047] The preparation method of the perovskite solar cell of the present embodiment comprises the following steps:

[0048] S21. Same as step S11 in Embodiment 1.

[0049] S22. Same as step S12 in Embodiment 1.

[0050] S23. Spin-coat the ZnO sol containing zinc acetylacetonate prepared in step S22 on the cleaned ITO-PEN flexible conductive substrate at a speed of 3000rpm for 30s, and finally anneal the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com