Surfactant for dry grinding-assisted modification of silica powder and preparation method of surfactant

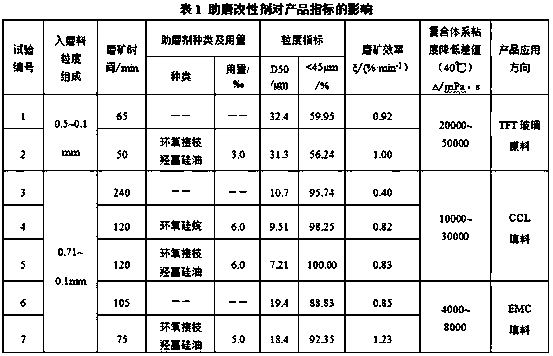

A surfactant and silicon micropowder technology, applied in chemical instruments and methods, silicone organic compounds, dyed organic silicon compound treatment, etc. It can improve the efficiency of dry grinding, improve mechanical and electrical properties, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

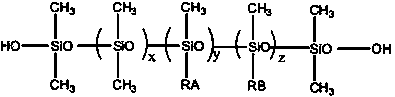

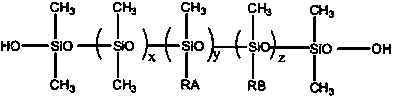

Image

Examples

Embodiment 1

[0024] Example 1: Taking epoxy-aminosilane co-modified hydroxyl-terminated silicone oil as an example:

[0025] (1) Preparation of ethanol solution of 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane: take 4.0mol 3-(2,3-epoxypropoxy)propylmethyldimethylsilane Add oxysilane to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid solution to adjust the pH to 3, stir slowly and uniformly for 2 hours, then add 5ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0026] (2) Preparation of EtOH solution of γ-aminopropylmethyldimethoxysilane: Take 4mol γ-aminopropylmethyldimethoxysilane and add it to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid Adjust the pH of the acetic acid solution to 3, stir slowly and uniformly for 2 hours, then add 5ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0027] (3) Ether diluent of low-viscosity hydroxyl-terminated silicone oil: Take 1.0mol of low-vis...

Embodiment 2

[0030] Embodiment 2: Taking epoxy-ethylene silane co-modified hydroxyl-terminated silicone oil as an example:

[0031] (1) Preparation of EtOH solution of 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane: take 5.0mol 3-(2,3-epoxypropoxy)propylmethyldimethylsilane Add oxysilane to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid solution to adjust the pH to 3, stir slowly and uniformly for 2 hours, then add 80ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0032] (2) Preparation of EtOH solution of vinylmethyldimethoxysilane: Take 4mol γ-aminopropylmethyldimethoxysilane and add it to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid solution to adjust the acetic acid The pH of the solution is 3, stir slowly and uniformly for 2 hours, then add 80ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0033] (3) Ether diluent of low-viscosity hydroxyl-terminated silicone oil: Take 1.0...

Embodiment 3

[0036] Embodiment 3: Taking epoxy-vinyl-aminosilane co-modified hydroxyl-terminated silicone oil as an example:

[0037] (1) Preparation of EtOH solution of 3-(2,3-epoxypropoxy)propylmethyldimethoxysilane: take 4.0mol 3-(2,3-epoxypropoxy)propylmethyldimethylsilane Add oxysilane to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid solution to adjust the pH to 3, stir slowly and uniformly for 2 hours, then add 60ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0038] (2) Preparation of EtOH solution of vinylmethyldimethoxysilane: Take 2mol γ-aminopropylmethyldimethoxysilane and add it to 1000ml 5% EtOH (volume ratio) aqueous solution, slowly add acetic acid solution to adjust the acetic acid The pH of the solution is 3, stir slowly and uniformly for 2 hours, then add 60ml of 1,2-octanediol, continue to stir slowly for 30 minutes, and set aside;

[0039] (3) Preparation of EtOH solution of γ-aminopropylmethyldimethoxysilane: Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com