Sludge desiccation system

A sludge drying and drying technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of drying efficiency, drying effect and stable operation of drying system, and the temperature cannot start auxiliary energy in time, etc. To achieve the effect of improving drying efficiency and drying effect, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

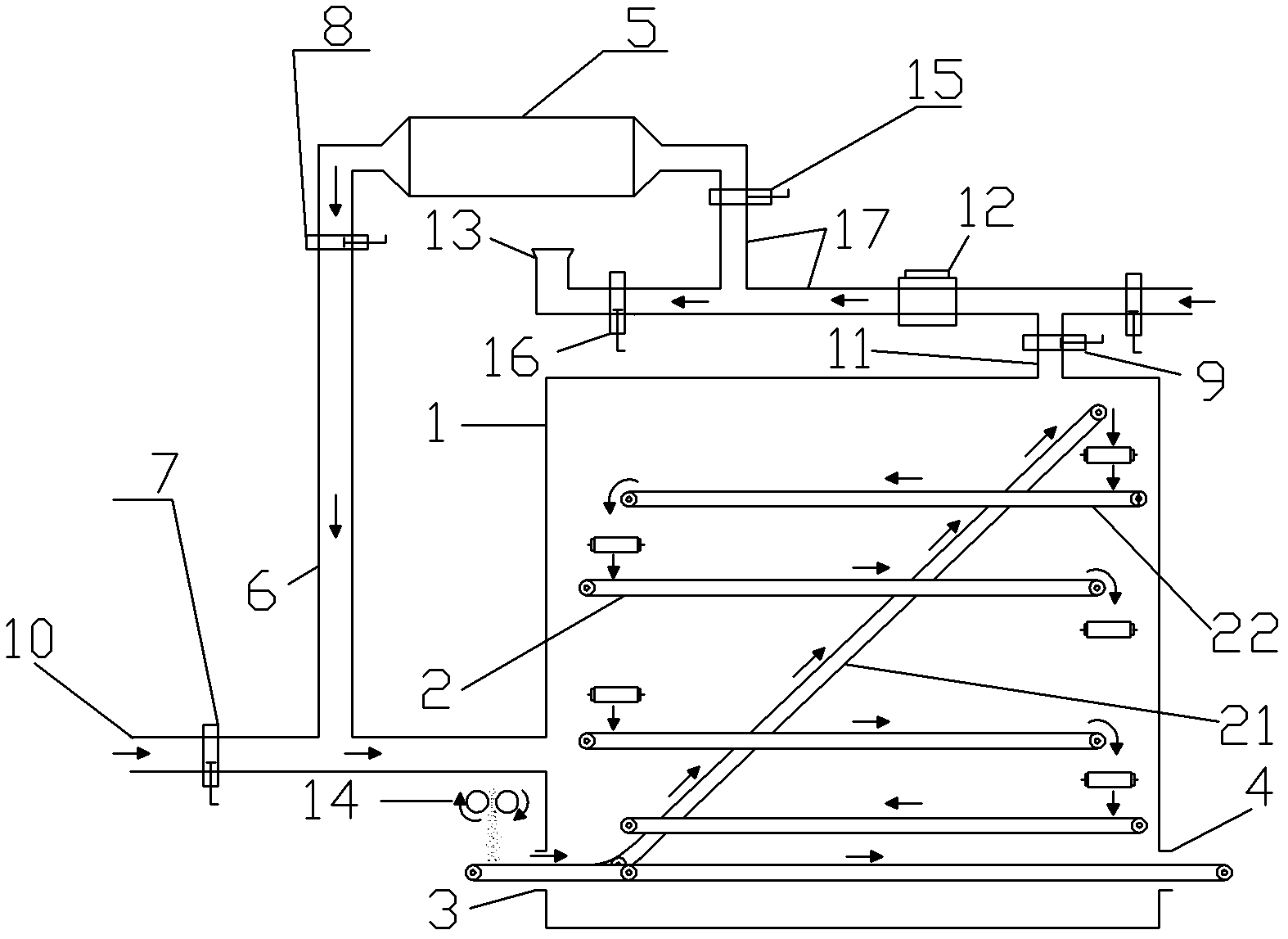

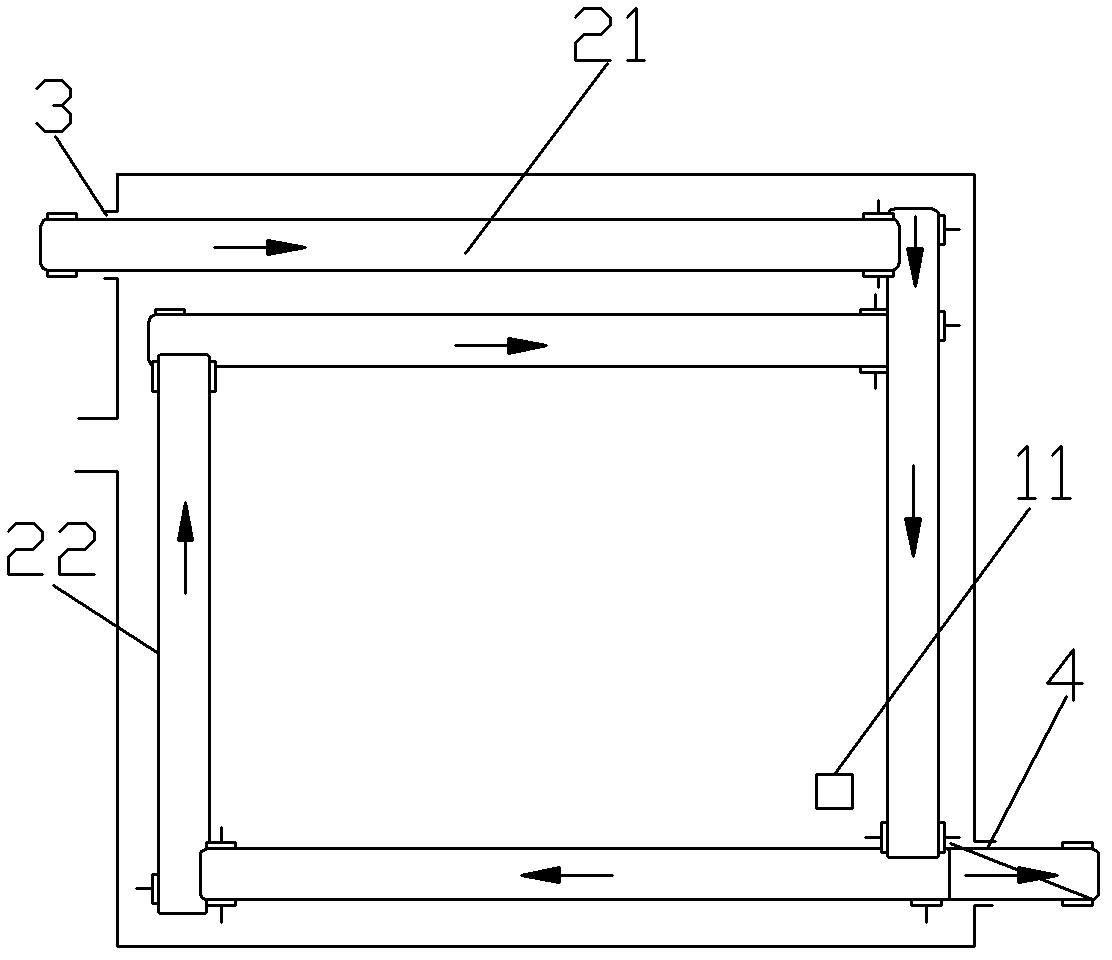

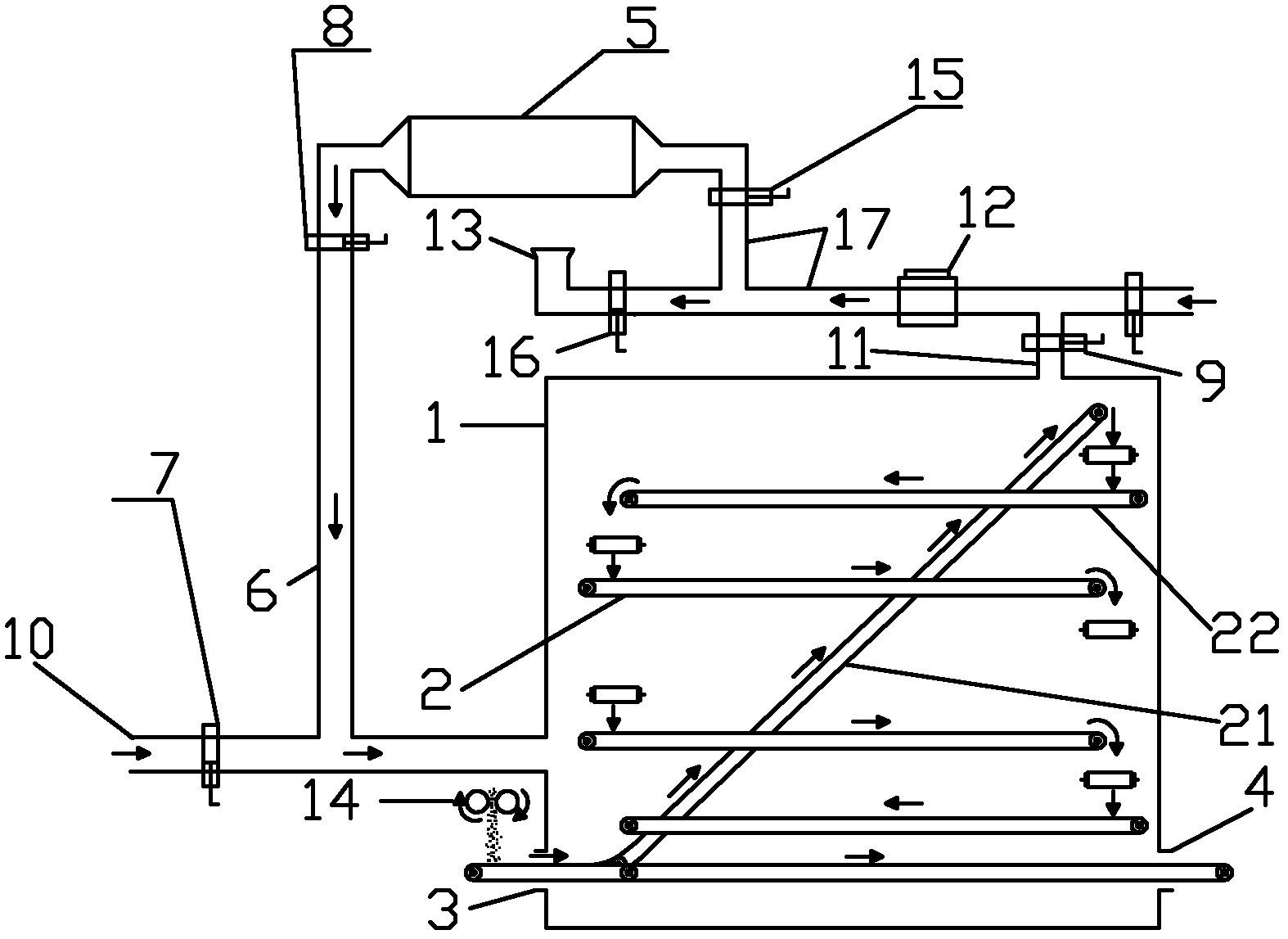

[0008] A sludge drying system, such as figure 1 , 2 As shown: the drying system includes a drying chamber 1, the drying chamber 1 communicates with the hot air pipeline 6 and the auxiliary heat source pipeline 10, and the drying chamber 1 includes a wet sludge inlet 3 and a dry sludge outlet 4 , moisture outlet 11, the drying chamber 1 also includes a sludge conveyor belt 2 located inside it, the hot air pipeline 6 communicates with the solar heat collector 5, and the solar heat collector 5 communicates with the solar heat collector 5 through the air duct 17 The fan 12 is connected, and the auxiliary heat source pipeline 10 is provided with a first temperature control valve 7 . The specific working state is: the wet sludge enters the drying chamber 1 through the wet sludge inlet 3, and runs on the conveyor belt 2, and is dried by hot air at the same time, until it is dried and discharged from the dry sludge outlet 4, and the evaporated water The air is discharged through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com