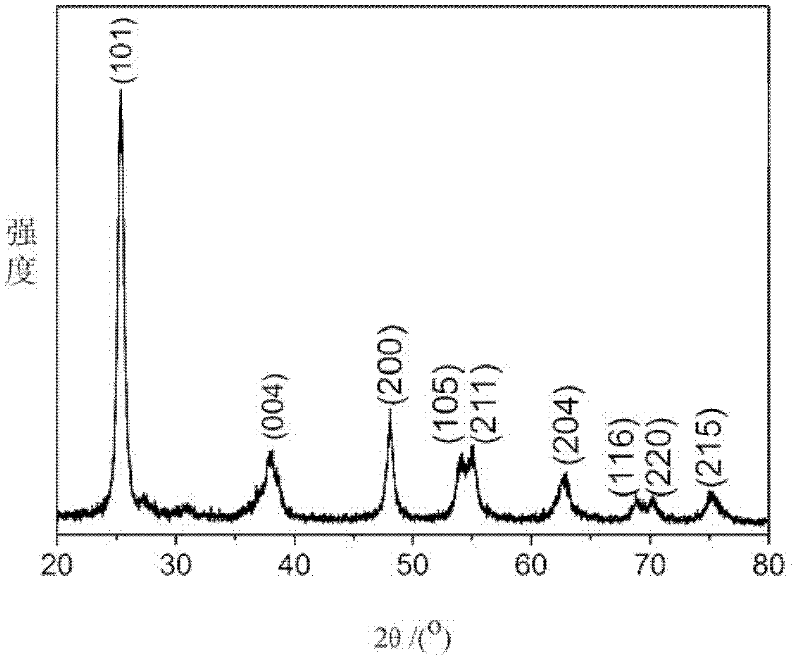

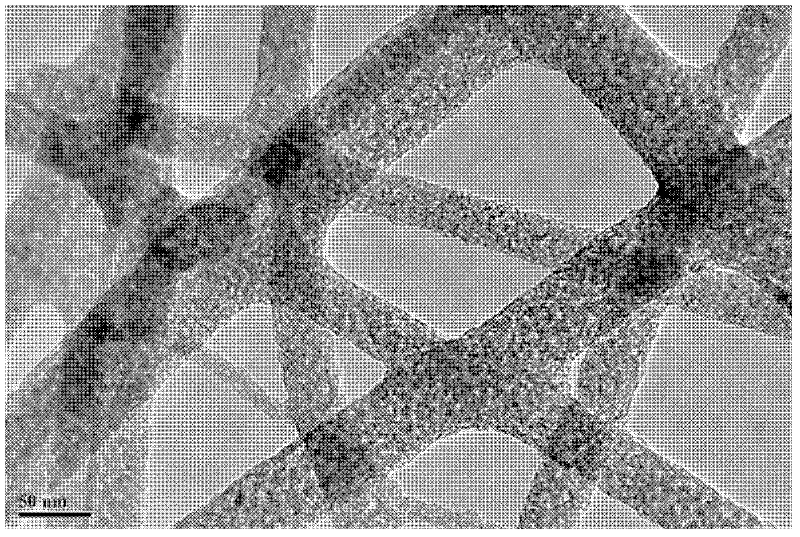

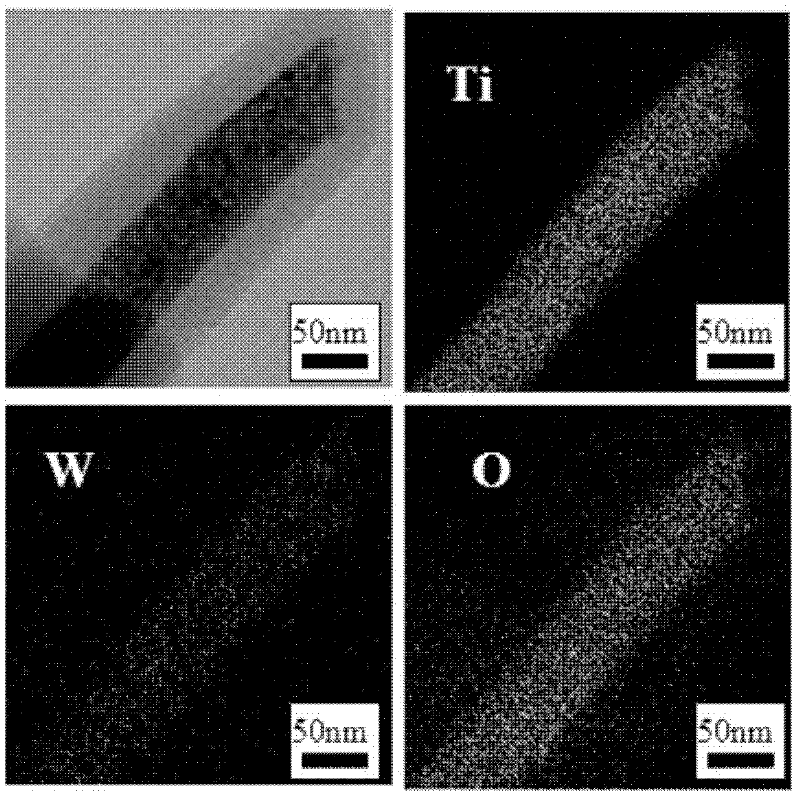

Method for preparing titanium-tungsten compound oxide nano-fiber

A composite oxide and nanofiber technology, applied in fiber treatment, spinning solution preparation, fiber chemical characteristics, etc., to achieve the effect of uniform particle size, high specific surface area, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Configuration of spinning solution

[0036] Slowly add 3.87g of tetrabutyl titanate solution dropwise into a mixed solution of 4ml of absolute ethanol and 3ml of glacial acetic acid under stirring, stir magnetically for 2 hours, add 0.13g of tungsten chloride to it, and continue stirring for 2 hours to obtain Solution A;

[0037] Weigh 1.40g of PVP into a beaker, and add absolute ethanol to it to 10ml, stir magnetically for 2 hours to obtain solution B;

[0038] Prepare 5ml of organic solvent (referred to as C), its substance and volume ratio is acetone: N-N dimethylformamide (DMF): acetylacetone=2: 1: 2;

[0039] Then solution A and solution B were mixed to form a jelly-like cross-linked product immediately, and organic solvent C was added and stirred for 2 hours to obtain a clear and transparent spinning solution.

[0040] (2) Electrospinning

[0041] The precursor spinning solution prepared above is spun on a self-assembled spinning device, the voltage is 13kV...

Embodiment 2

[0045] (1) Configuration of spinning solution

[0046] Slowly add 3.70g of tetrabutyl titanate solution dropwise into a mixed solution of 3ml of absolute ethanol and 4ml of glacial acetic acid under stirring, stir magnetically for 2 hours, add 0.28g of tungsten chloride to it, and continue stirring for 2 hours to obtain Solution A;

[0047] Weigh 1.40g of PVP into a beaker, and add absolute ethanol to it to 10ml, stir magnetically for 2 hours to obtain solution B;

[0048] Prepare 6ml of organic solvent (referred to as C), its substance and volume ratio is acetone: N-N dimethylformamide (DMF): acetylacetone=2: 2: 1;

[0049] Then solution A and solution B were mixed to form a jelly-like cross-linked product immediately, and organic solvent C was added and stirred for 2 hours to obtain a clear and transparent spinning solution.

[0050] (2) Electrospinning

[0051] The precursor spinning solution prepared above was spun on a self-assembled spinning device with a voltage of 1...

Embodiment 3

[0055] (1) Configuration of spinning solution

[0056] Slowly add 3.06g of tetrabutyl titanate solution dropwise into a mixed solution of 4ml of absolute ethanol and 3ml of glacial acetic acid under stirring, stir magnetically for 2 hours, then add 0.93g of tungsten chloride to it, and continue stirring for 2 hours to obtain Solution A;

[0057] Weigh 1.40g of PVP into a beaker, and add absolute ethanol to it to 10ml, stir magnetically for 2 hours to obtain solution B;

[0058] Prepare 5ml of organic solvent (referred to as C), its substance and volume ratio is acetone: N-N dimethylformamide (DMF): acetylacetone=1: 2: 2;

[0059] Then solution A and solution B were mixed to form a jelly-like cross-linked product immediately, and organic solvent C was added and stirred for 2 hours to obtain a clear and transparent spinning solution.

[0060] (2) Electrospinning

[0061] The precursor spinning solution prepared above is spun on a self-assembled spinning device, the voltage is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com