Driven gear device for motorcycle engine

A technology of driven gear and engine, applied in transmission parts, transmission control, belt/chain/gear, etc., can solve the problems of engine stall, impact of engine parts, danger of separation of people and vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

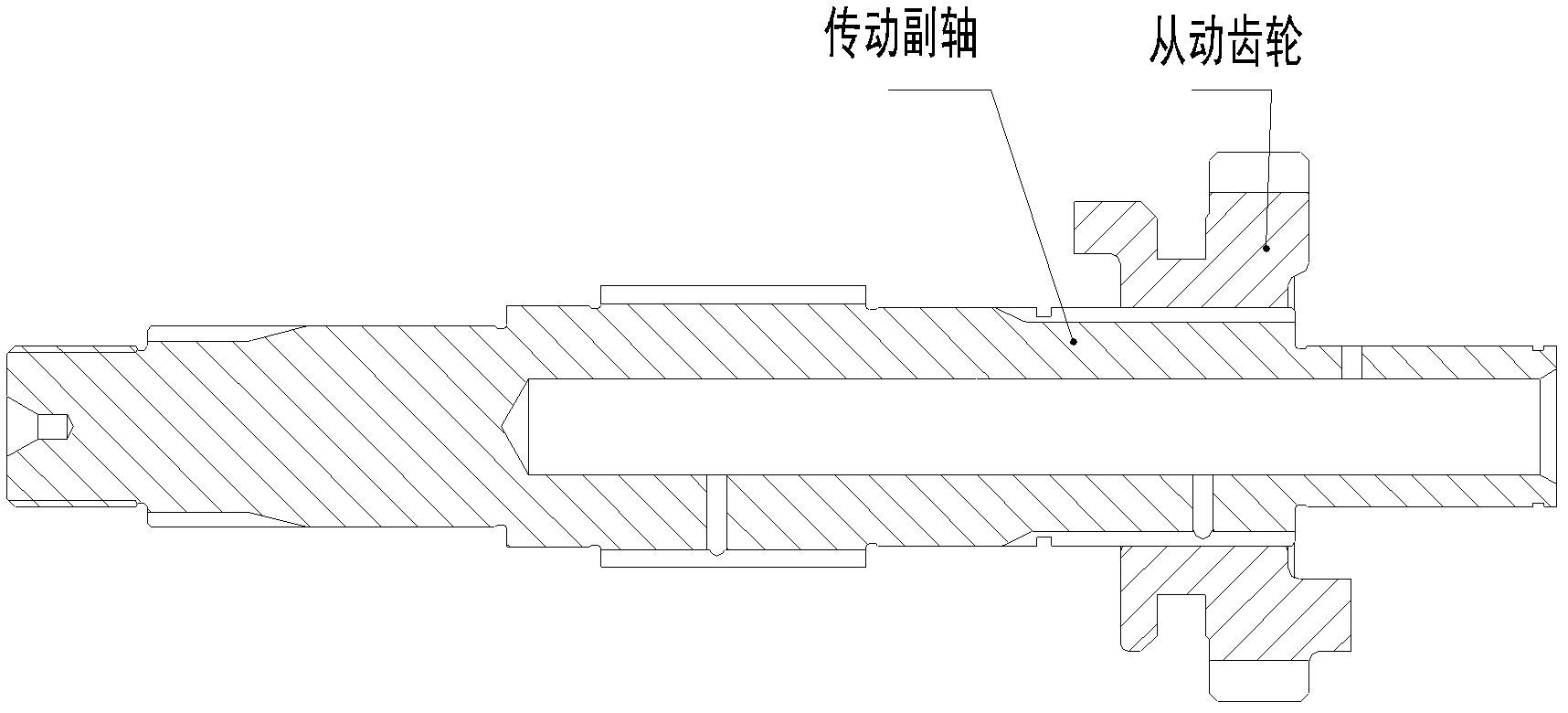

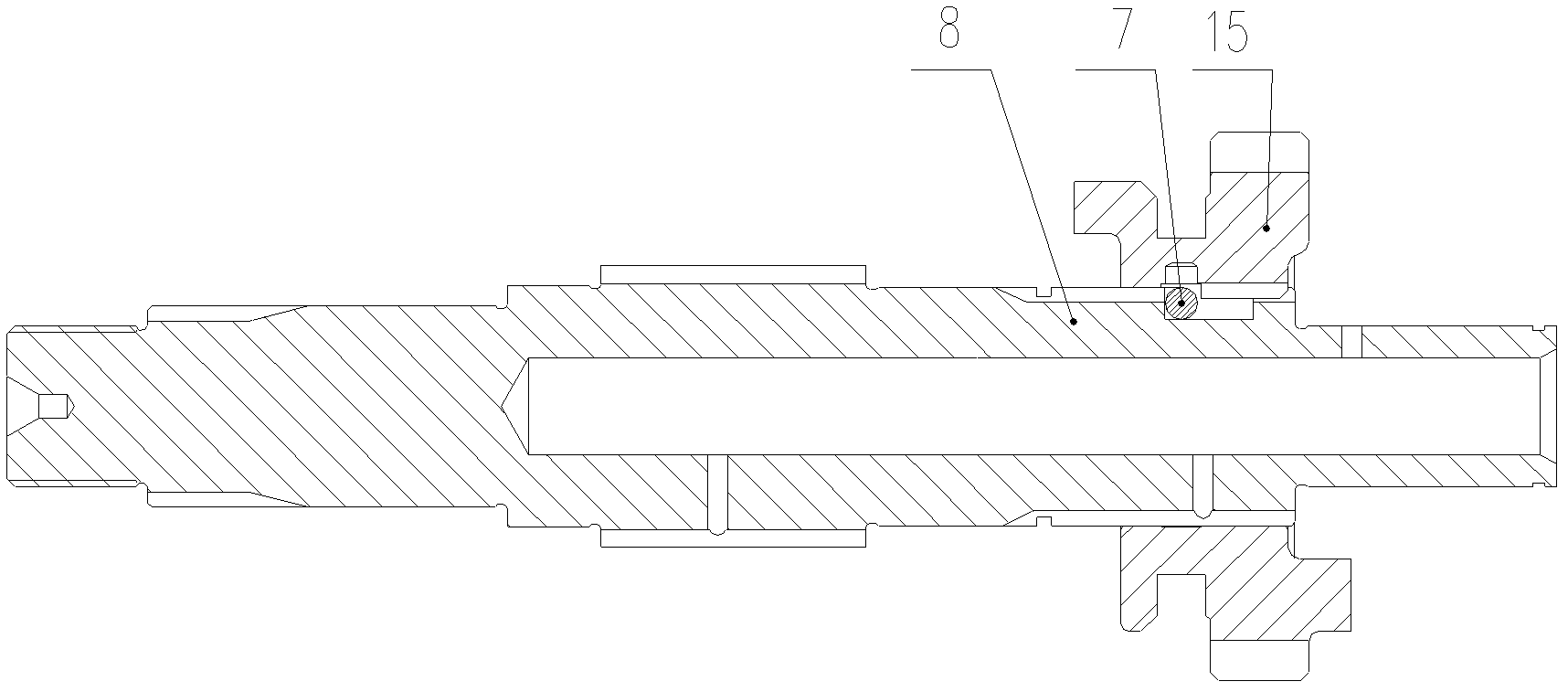

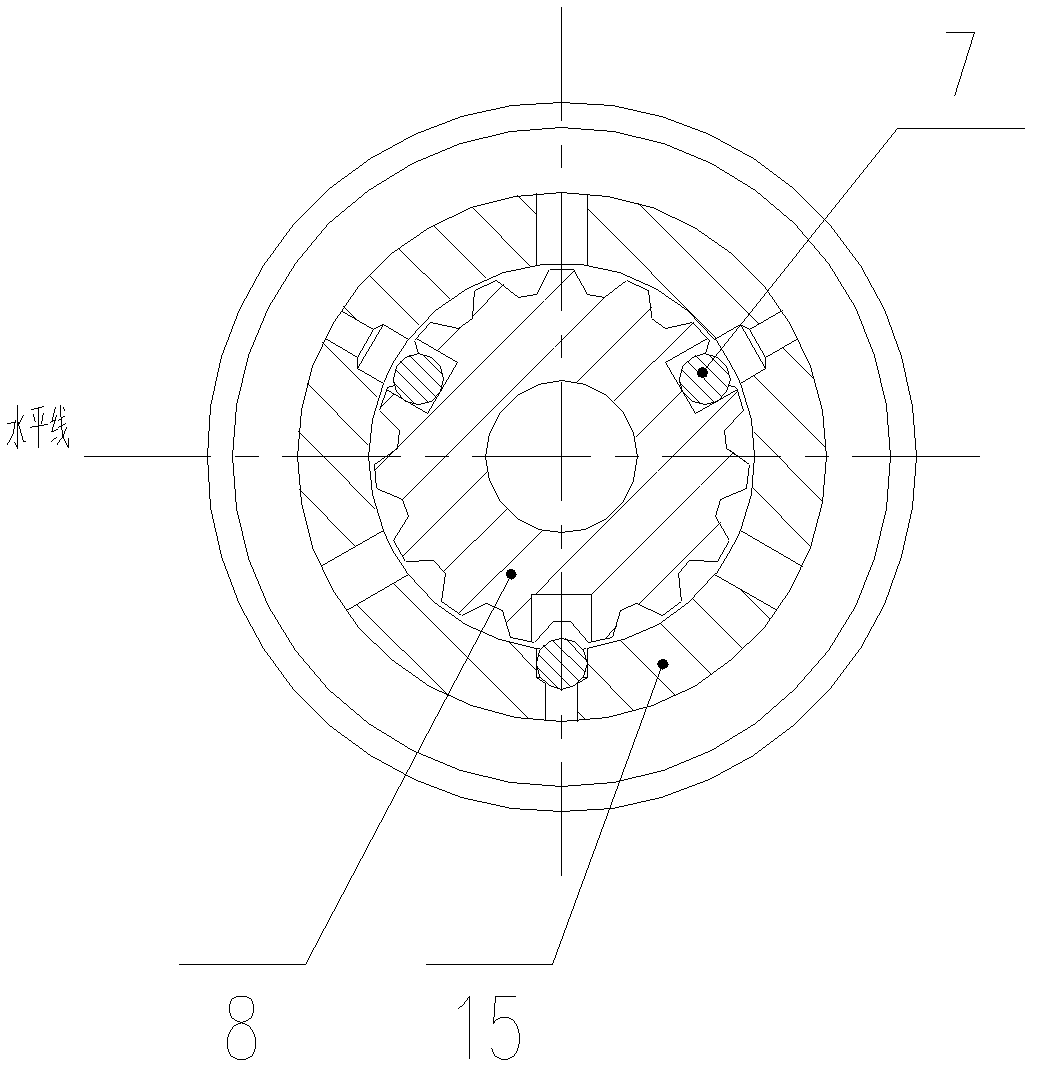

[0016] The embodiment of the present invention transforms the traditional driven gear device. An inner spline is arranged on the inner surface of the driven gear, and a hole groove is arranged on the inner spline, and a steel ball is installed in the hole groove. The diameter of the steel ball is smaller than the depth of the hole groove, and the corresponding The transmission sub-shaft is provided with an external spline and a chute, the chute corresponds to the position of the hole of the driven gear, and the depth of the chute is smaller than the diameter of the steel ball. When the driven gear device starts the motorcycle, the steel ball in the hole groove above the horizontal line will fall into the chute of the transmission countershaft due to its own gravity, so that the sliding of the driven gear is limited, and the motorcycle cannot be hung into the secondary shaft. The gears above and above can only be started in one gear, which avoids the danger of separation of peop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com