Device and method for measuring operating axis of barrel of rotary kiln

A technology for measuring devices and rotary kilns, applied in measuring devices, instruments, etc., can solve problems such as unreasonable assumptions, complicated operations, and expensive systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The measuring device and measuring method of the rotary kiln cylinder running axis of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

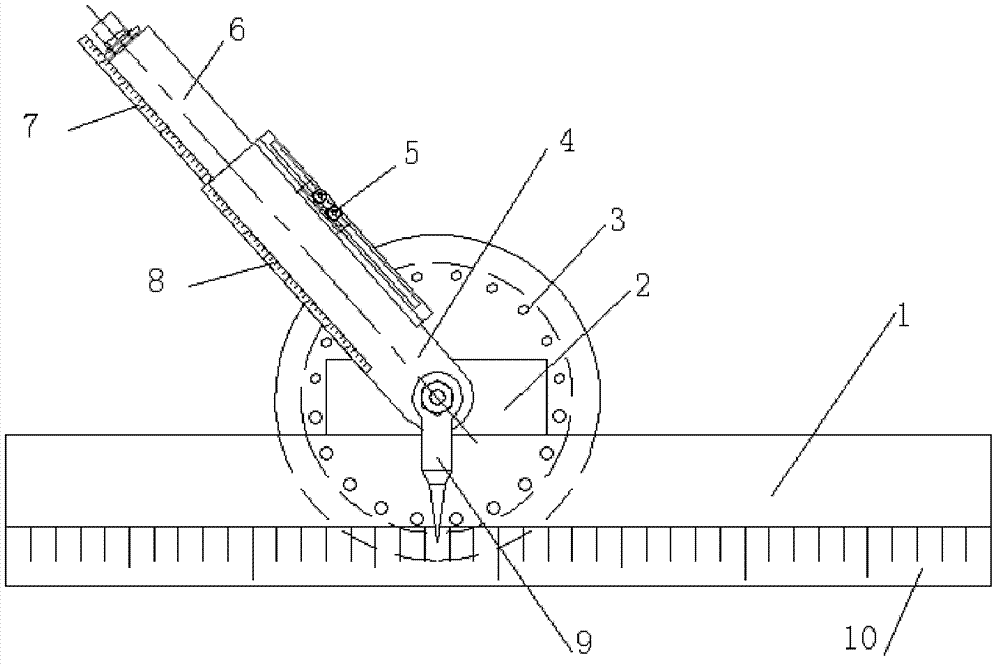

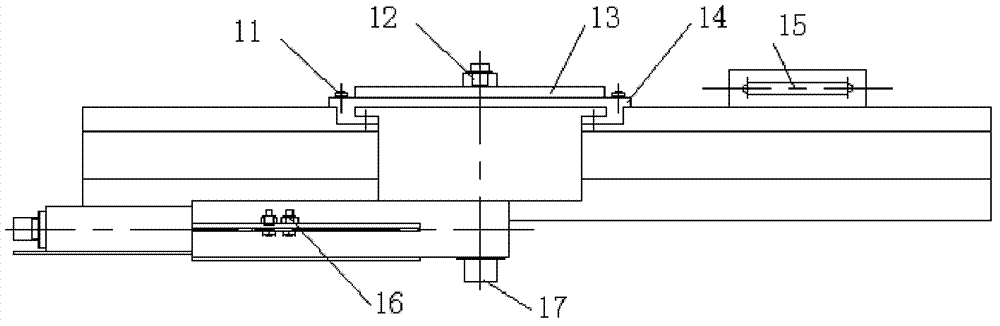

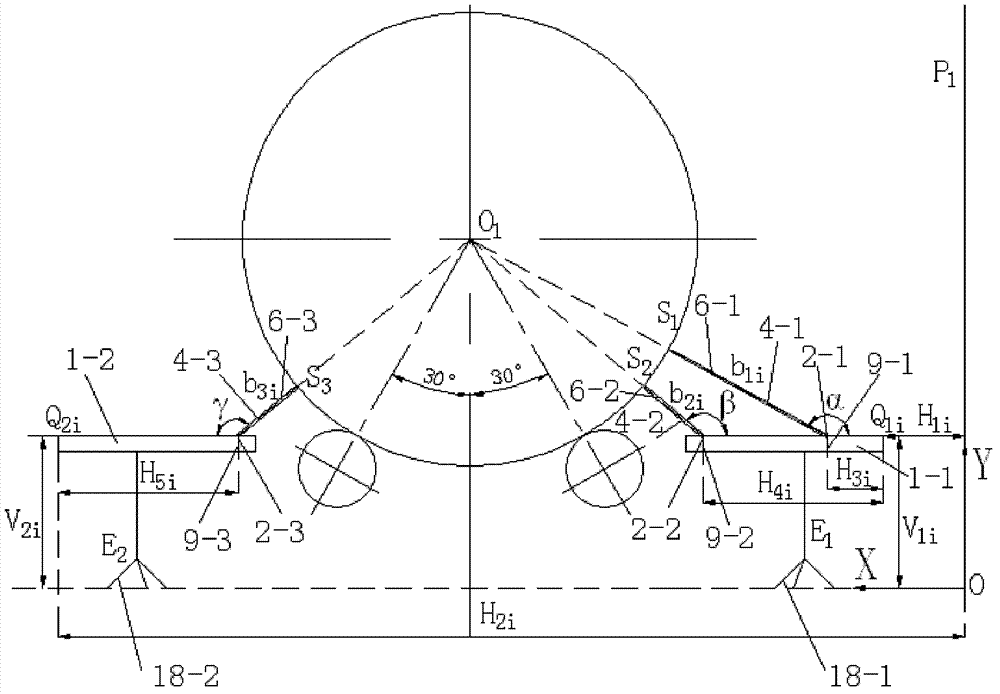

[0053] Such as figure 1 , figure 2 with image 3 As shown, the measuring device adopted in the measuring method of the present invention includes: mounting bracket, slide bar 1, pointer 9, slide block 2, connecting rod 3, outer fixed cylinder 4, inner telescopic cylinder 6, inner cylinder scale 7, outer Tube scale 8, slide rod scale 10, connecting shaft 17, rotating indexing plate 13, fixed indexing plate 14, level 15, bolt 5, connecting shaft nut 12, barrel nut 16 and screw 11; described mounting bracket It is a tripod with adjustable height; the slide bar 1 is installed on the mounting bracket; the upper surface of the slide bar 1 is a plane, and the slide bar 1 has a built-in slide bar scale 10 and a level 15; the slide block 2 Slidingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com