Method for predicting wear rate of radiant tube of downer rapid pyrolysis furnace

A pyrolysis furnace and radiant tube technology, which is applied in the field of coal chemical industry, can solve the problems affecting the high-efficiency, long-term, safe and stable operation of the fast pyrolysis furnace device, the erosion and wear of the radiant tube, and unsafe economic losses, so as to reduce unsafe factors and economic loss, strong applicability, and the effect of ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

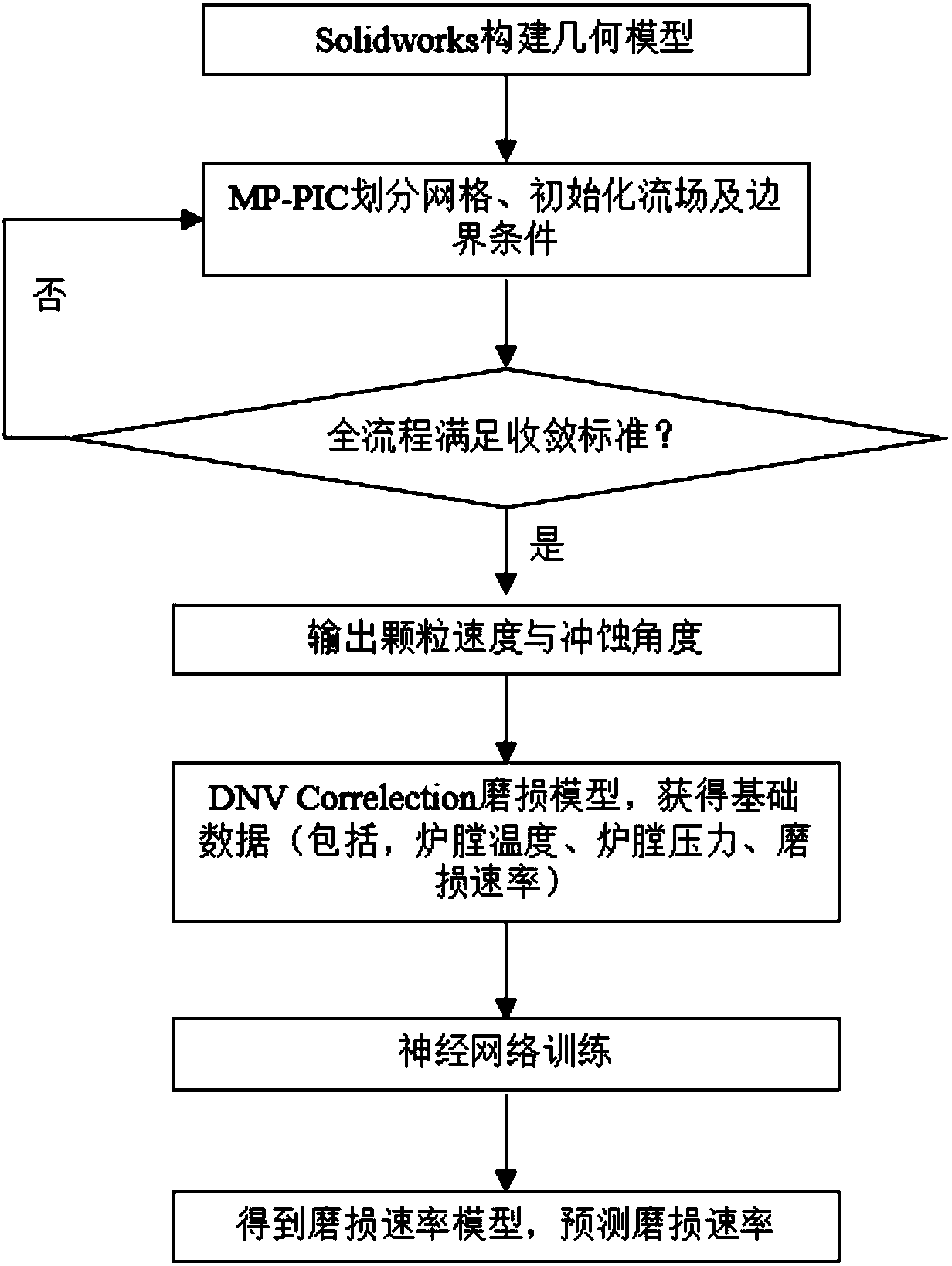

[0085] A method for predicting the wear rate of the radiant tube of a vertical square regenerative pulverized coal fast pyrolysis furnace, comprising the following steps:

[0086] 1) Use Solidworks software to conduct 1:1 geometric modeling of the vertical square regenerative pulverized coal rapid pyrolysis furnace device. The height of the pyrolysis furnace is 12m, the top is a rectangle of 2.0×3.0m, and the bottom is a Rectangular, 40 radiant tubes are arranged inside, 20 layers are arranged in total, and two radiant tubes are arranged on each layer;

[0087] The diameter of the radiant tubes used is 180mm, and the horizontal and vertical distances between two radiant tubes are 300mm respectively.

[0088] 2) Use the MP-PIC method to divide the grid, and set the coal powder particles and gas properties according to the actual physical properties; the average particle size of the coal powder used is 0.5mm, and the true density is 1400kg / m 3 ;Powdered coal is uniformly fed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com