Reflectance distribution curve modeling method, thickness measurement scheme and thickness measurement reflectometer using same

A modeling method and degree distribution technology, which is applied in semiconductor/solid-state device testing/measurement, instruments, measuring devices, etc., can solve problems such as inconsistencies, and achieve the effect of precise detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the method for modeling the reflectance distribution curve of the present invention, the method for thickness detection using the method, and the thickness detection reflector will be described in detail below with reference to the accompanying drawings.

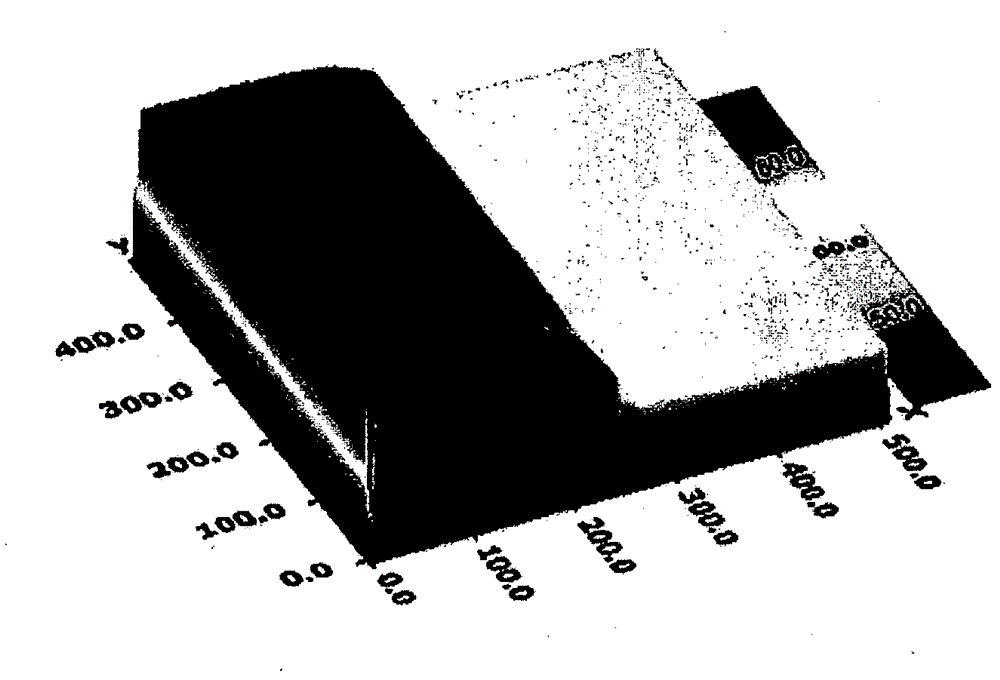

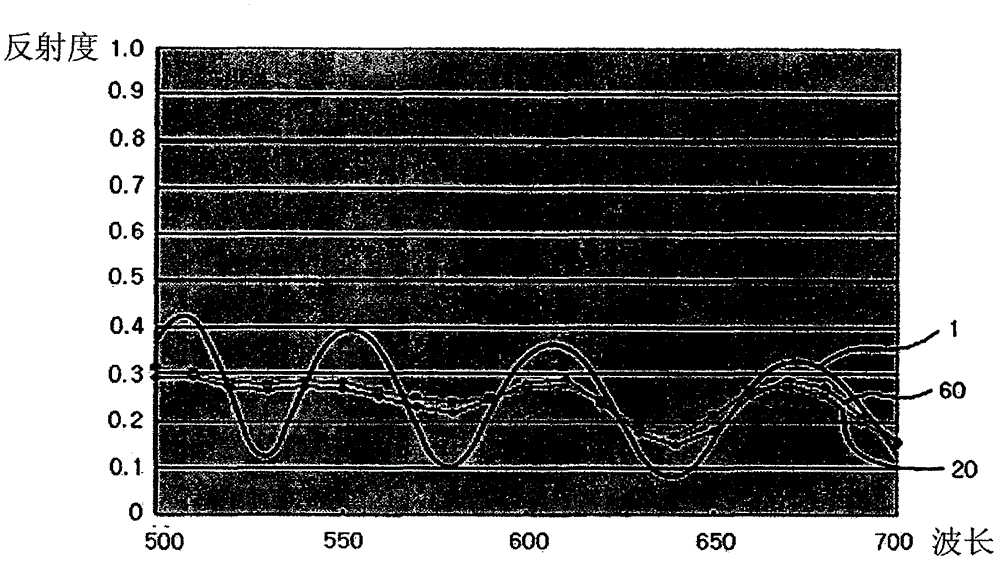

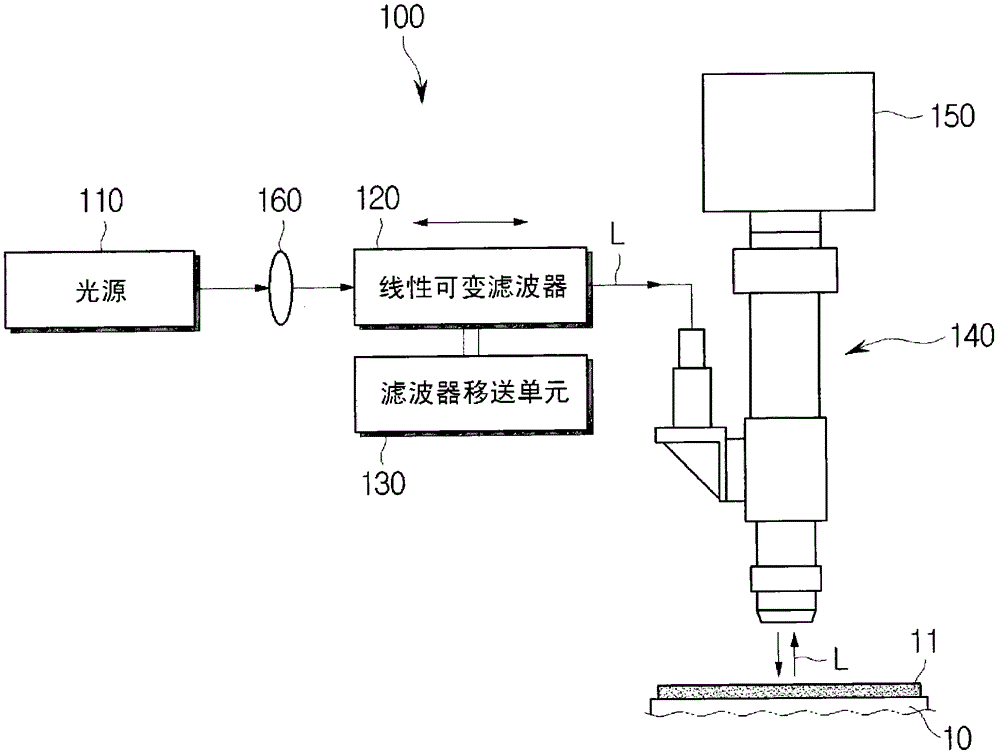

[0023] figure 1 is a schematic diagram of an embodiment of the thickness detection reflector of the present invention; figure 2 is through figure 1 Intensity distribution curve of the linear variable filter band-passed light in the thickness detection reflectometer; Figure 7 It is a drawing for explaining an example of the surface shape of the detected thin film layer.

[0024] Please refer to figure 1 , figure 2 and Figure 7 The thickness detection reflector 100 of this embodiment includes a light source 110 , a linear variable filter 120 , a filter transfer unit 130 , a condenser lens 160 , an optical system 140 and an imaging unit 150 .

[0025] The light source 110 is used for irradiating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com