Deashing gas heating system for preventing dewing in bag filtration

A technology of gas heating and bag-type dedusting, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. Effect of eliminating dust condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

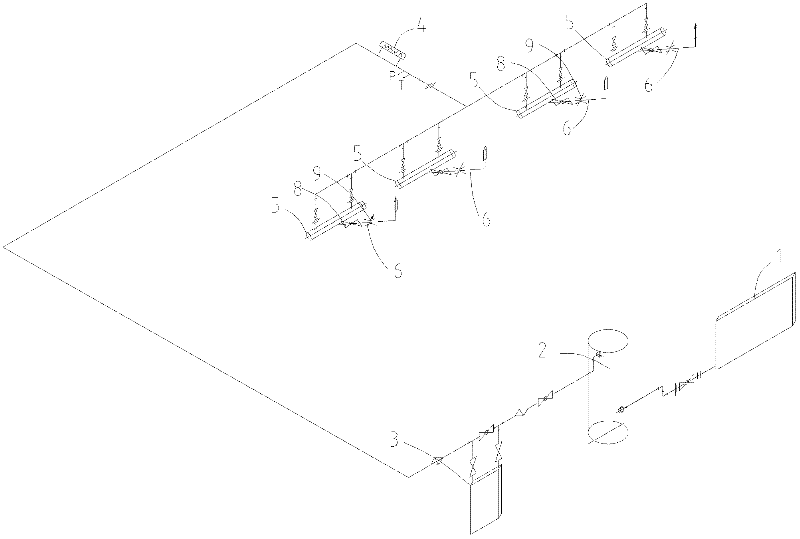

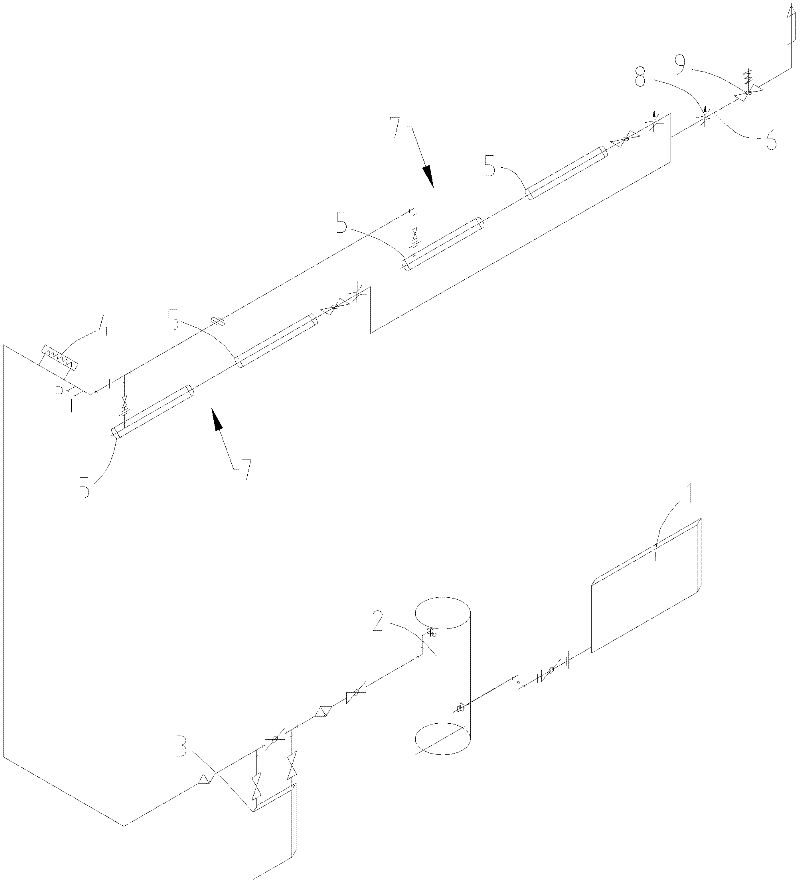

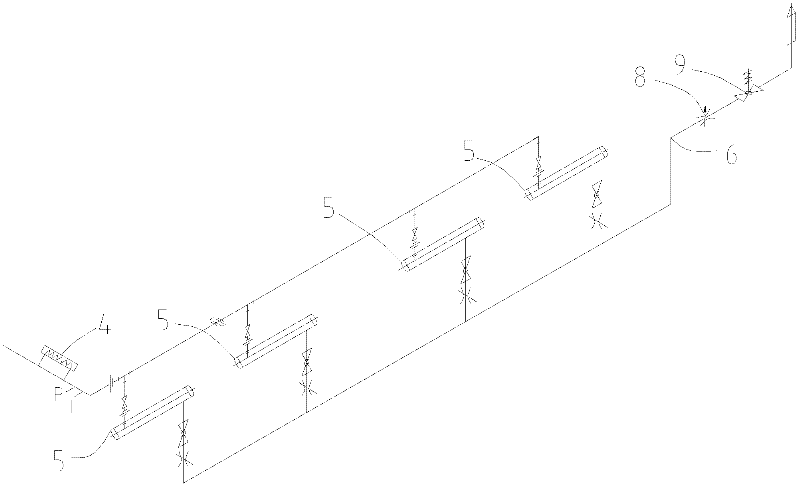

[0016] figure 1 Shows a form of dust removal gas system for bag filter, the dust removal gas system includes a gas tank 2 for storing the dust removal gas, an electric heater 4 whose inlet is connected to the outlet of the gas tank 2, an inlet A plurality of gas distribution boxes 5 connected in parallel to the outlet of the electric heater 4, the inlet of the gas tank 2 is connected with a screw compressor 1, and the dust removal gas is pressurized into the gas tank 2 for storage through the screw compressor 1, and the dust is removed Compressed air is used as the gas, and a freeze dryer 3 is connected between the gas tank 2 and the electric heater 4. Through the freeze dryer 3, the soot-cleaning gas is dew-free to remove the moisture in the soot-cleaning gas before heating, and the soot-cleaning gas After the moisture is removed by the freeze d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com