Device for ilmenite concentrate microwave drying and application method thereof

A technology for microwave drying and titanium concentrate, which is used in drying solid materials, lighting and heating equipment, drying, etc. Avoid decaying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

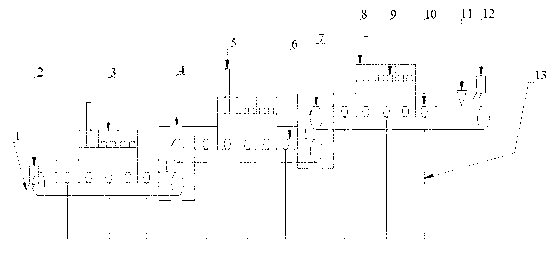

[0027] Implementation mode one: if figure 1 As shown, the equipment structure of the microwave drying titanium concentrate of this embodiment includes three sections of microwave heating devices, and the three sections of microwave heating devices are arranged end to end in a stepped distribution; each section of microwave heating devices includes a belt conveyor and a microwave heating chamber body 3, the belt conveyor passes through the microwave heating cavity 3; the microwave heating device of the highest step has a vibrating feeder 12 at one end, and the microwave heating device of the lowest step has a discharge device 2. The microwave heating device of highest step has 12 one ends of vibrating feeder to be equipped with material layer baffle plate 11, and material layer baffle plate 11 is installed in the place ahead of the vibrating feeder 12 of belt conveyor rotation direction. The feed port of the vibrating feeder 12 and the discharge port of the discharge device 2 a...

Embodiment approach 2

[0029] Implementation mode two: if figure 1 As shown, the equipment structure of the microwave drying titanium concentrate of this embodiment includes three sections of microwave heating devices, and the three sections of microwave heating devices are arranged end to end in a stepped distribution; each section of microwave heating devices includes a belt conveyor and a microwave heating chamber body 3, the belt conveyor passes through the microwave heating cavity 3; the microwave heating device of the highest step has a vibrating feeder 12 at one end, and the microwave heating device of the lowest step has a discharge device 2. The microwave heating device of highest step has 12 one ends of vibrating feeder to be equipped with material layer baffle plate 11, and material layer baffle plate 11 is installed in the place ahead of the vibrating feeder 12 of belt conveyor rotation direction. The feed port of the vibrating feeder 12 and the discharge port of the discharge device 2 a...

Embodiment approach 3

[0031] Implementation mode three: if figure 1 As shown, the equipment structure of the microwave drying titanium concentrate of this embodiment includes three sections of microwave heating devices, and the three sections of microwave heating devices are arranged end to end in a stepped distribution; each section of microwave heating devices includes a belt conveyor and a microwave heating chamber body 3, the belt conveyor passes through the microwave heating cavity 3; the microwave heating device of the highest step has a vibrating feeder 12 at one end, and the microwave heating device of the lowest step has a discharge device 2. The microwave heating device of highest step has 12 one ends of vibrating feeder to be equipped with material layer baffle plate 11, and material layer baffle plate 11 is installed in the place ahead of the vibrating feeder 12 of belt conveyor rotation direction. The feed port of the vibrating feeder 12 and the discharge port of the discharge device 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com