Motor stator core automatic riveting device

A motor stator and power device technology, which is applied in the field of automatic riveting devices for motor stator cores, can solve problems such as rising labor costs, low work efficiency, and increasing the burden on small processing plants, so as to achieve safe and convenient operation, avoid safety accidents, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

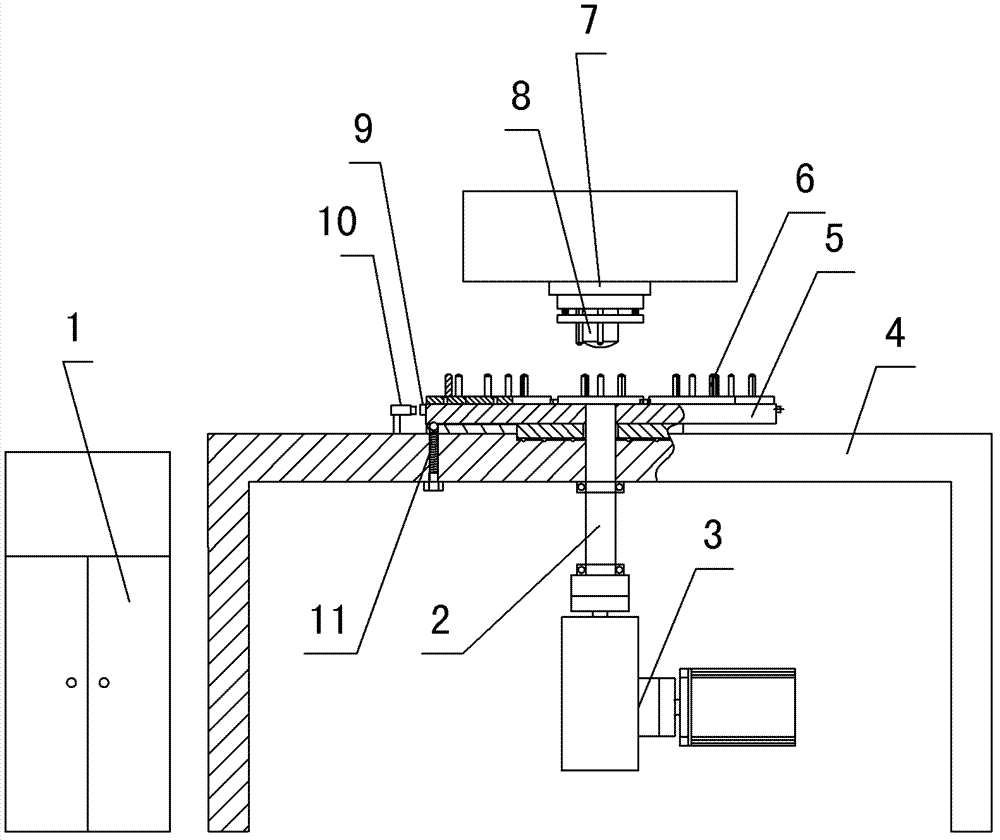

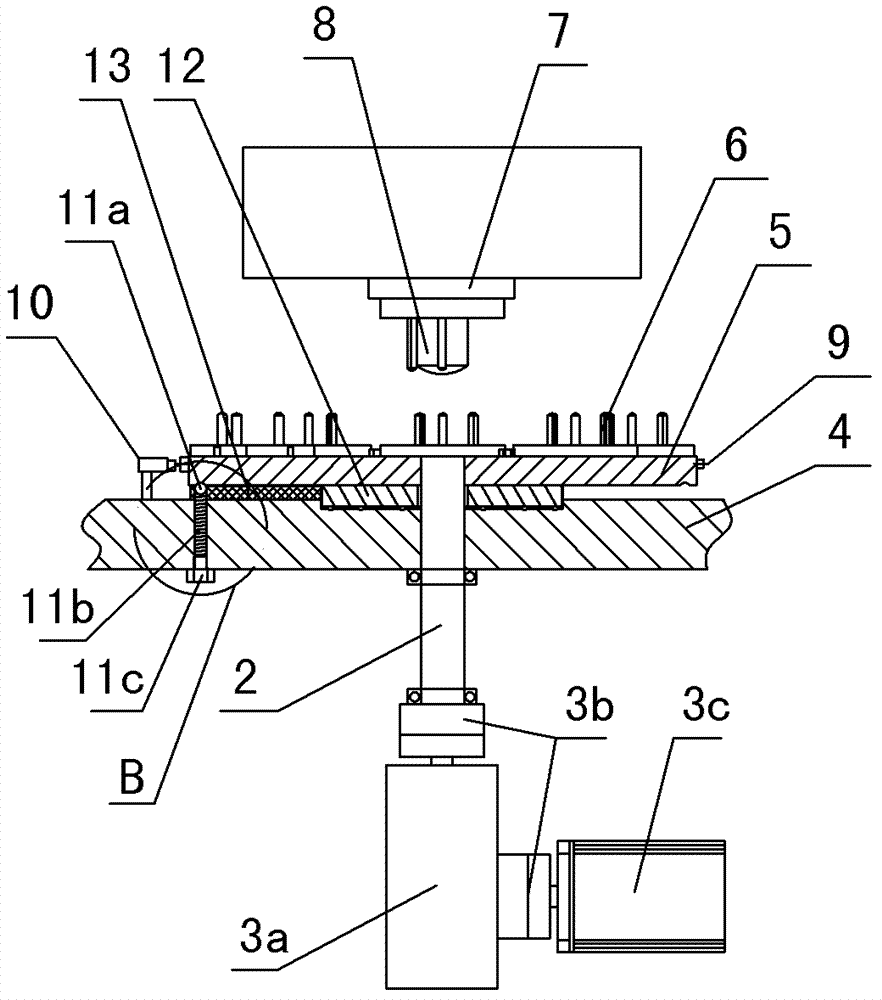

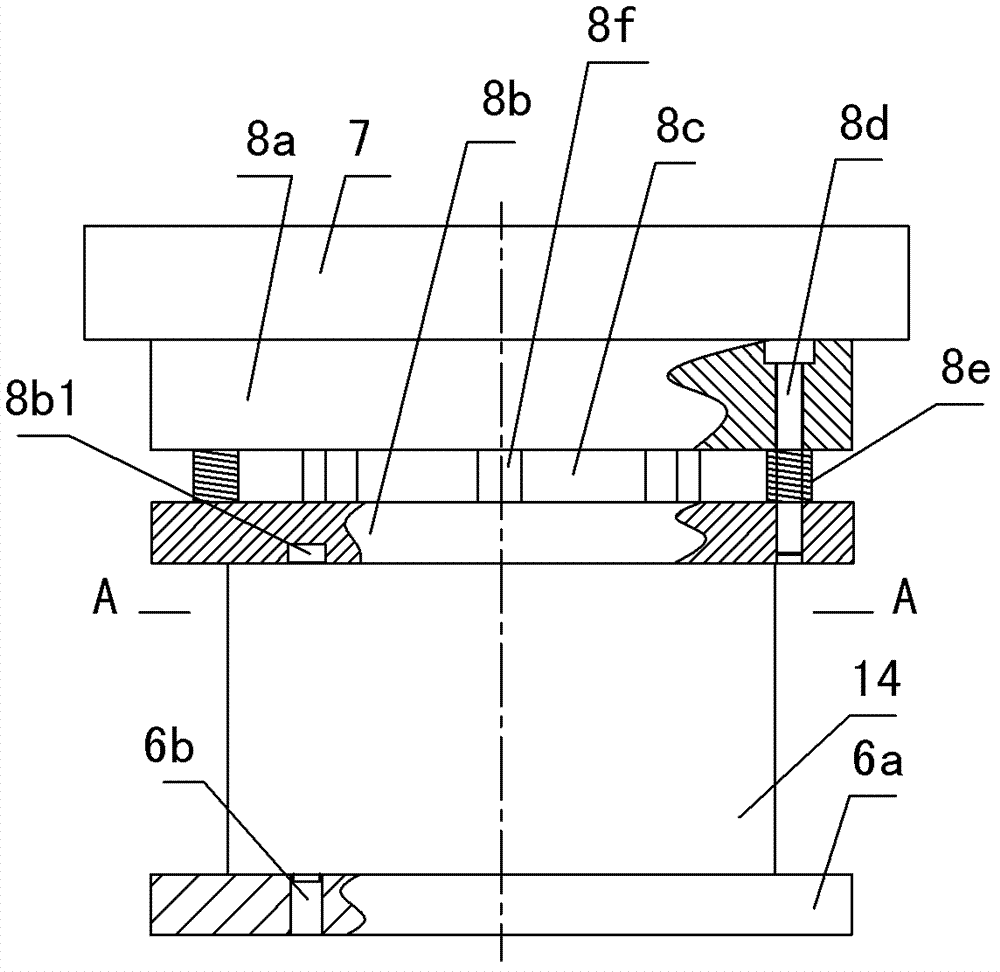

[0022] Embodiment 1: refer to Figure 1-8 . The motor stator core automatic riveting device includes a punching machine, the punching machine includes a machine table 4 and a mold handle 7, the upper end of the machine table 4 is provided with a turntable 5, one side of the turntable 5 is located between the machine table 4 and the mold handle 7, and the machine table 4 A power unit 3 is provided below, and the center of the turntable 5 is connected to the power unit 3 through a rotating shaft 2. The upper end of the turntable 5 is provided with a number of lower dies 6 evenly arranged around the rotating shaft 2. The lower end of the mold handle 7 is connected to each lower die. The mold 6 is matched with the upper mold 8 that is connected, and the power unit 3 includes a gearbox 3a and a motor 3c. The limit block 9 matched with the upper mold 8, the limit switch 10 that can be matched and connected with each limit block 9 is provided on the outside of the turntable 5, and t...

Embodiment 2

[0024] Embodiment 2: refer to Figure 1-8 . Place the motor stator iron core 14 on the lower mold on the turntable 5 in turn, the lower positioning pin 6c blocks the positioning hole 14a of the motor stator iron core 14, after pressing the start switch, the PLC controller controls the motor 3c to start running, after After the gearbox 3a connected by the coupling 3b is adjusted in speed, the power output by the motor is transmitted to the rotating shaft 2, and the turntable 5 is rotated through the rotating shaft 2 until the limit block 9 reaches the limit switch 10. At this time, The PLC controller controls the motor 3c to stop running, and at the same time, the positioning device positions the turntable, that is, the steel ball 11a pushes into the limit hole 5a to prevent it from continuing to rotate due to inertia and can accurately locate the position of the turntable 5, so that the stator core of the motor 14 is directly below the mold handle 7, and then the PLC controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com