Backlight module and manufacturing method thereof as well as display device provided with backlight module

A technology of backlight module and light source device, which is applied in the direction of lighting devices, fixed lighting devices, lighting device components, etc., can solve the problems of second joint loosening, assembly interference, waste of manpower and time, etc., to avoid disassembly, The effect of preventing poor assembly and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

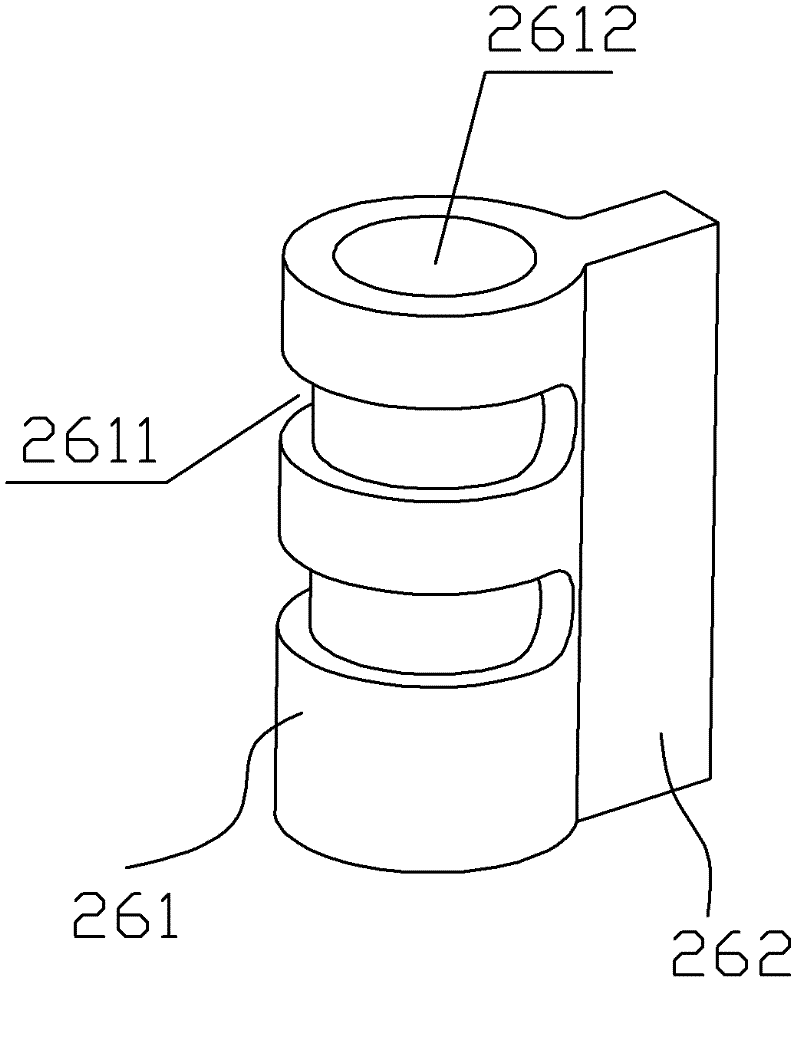

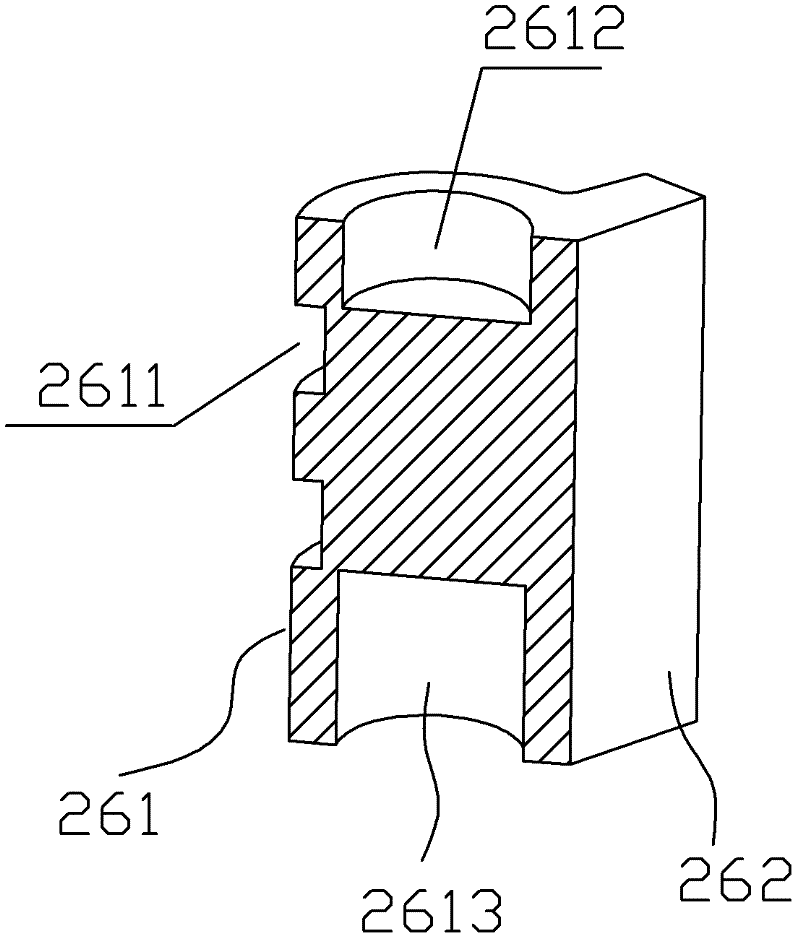

[0024] Please refer to Figure 2A , which shows a cable management device according to an embodiment of the present invention. The cable management device 26 includes a main body 261 and a convex portion 262 . In this embodiment, the body 261 is cylindrical, and the convex portion 262 is a cuboid, and the two are integrally formed by an injection molding process. The cross-section of the protrusion 262 is not limited to a rectangle, and in other embodiments, it can also be a trapezoid, a semicircle and other shapes. In order to enhance the effect of cable management, there are two cable management slots 2611 on the surface of the main body 261 in this implementation. The depth and width of the cable management slots 2611 are determined according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com