Multi-pole drive power supply for ultraviolet (UV) lamp

A pole drive and power supply technology, applied in the field of power supply, can solve the problems of increased cathode loss, failure to light up, large heat generation, etc., and achieve the effects of reducing volume and weight, increasing power density, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

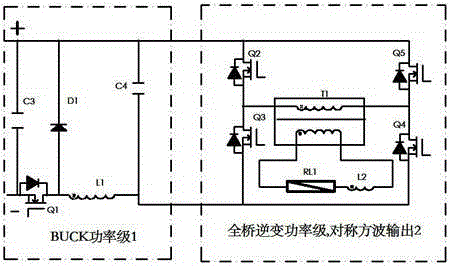

Examples

specific Embodiment 2

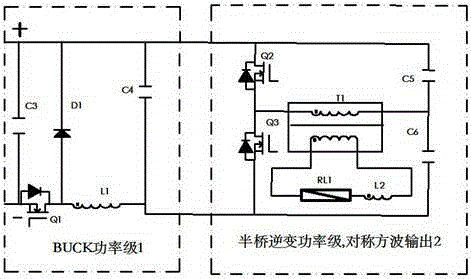

[0041] refer to figure 2 As shown, a UV lamp multi-stage drive power supply includes a BUCK power regulation circuit 1 and a symmetrical half-bridge inverter circuit 2, wherein the BUCK power regulation circuit 1 includes a MOSFET switch tube Q1, a freewheeling diode D1, and an energy storage filter inductor L1. The input capacitor C3 is connected between the input positive and negative bus bars, and the output capacitor C4 is connected between the output positive bus bar and the negative bus bar; the symmetrical half-bridge inverter circuit 2 includes switching tubes Q2, Q3, capacitors C5, C6, and an output transformer. T1, current limiting inductor L2. The drain of MOSFET switch Q2 and one end of capacitor C5 are connected to the output positive bus of the BUCK circuit, the source of switch Q3 and one end of capacitor C6 are connected to the output negative bus of the BUCK circuit, and the transformer T1 One end of the primary side is connected to the source of MOSFET swit...

specific Embodiment 3

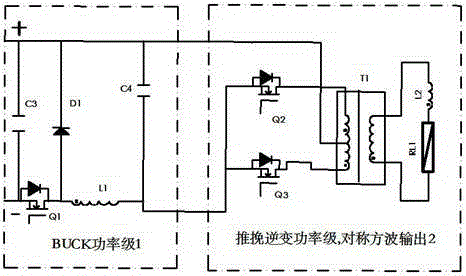

[0043] refer to image 3 As shown, a UV lamp multi-stage drive power supply includes a BUCK power regulation circuit 1 and a push-pull bridge inverter circuit 2 . The BUCK power regulation circuit 1 includes a MOSFET switch tube Q1, a freewheeling diode D1, an energy storage filter inductor L1, an input capacitor C3 connected between the input positive and negative bus bars, and an output capacitor C4 connected between the output positive bus bar and the negative bus bar The push-pull bridge inverter circuit 2 includes MOSFET switch tubes Q2, Q3, output transformer T1, and current-limiting inductor L2; the sources of the MOSFET switch tubes Q2 and Q3 of the push-pull bridge inverter circuit are connected to the output negative of the BUCK circuit at the same time On the bus, the two ends of the primary side of the transformer T1 are respectively connected to the drains of the MOSFET switch tubes Q2 and Q3, the neutral tap of the primary side of the transformer T1 is connected ...

specific Embodiment 4

[0046] refer to Figure 4 As shown, a UV lamp multi-level drive power supply, including BUCK power regulation circuit 1, asymmetrical half-bridge inverter circuit 2; wherein BUCK power regulation circuit 1 includes MOSFET switch tube Q1, freewheeling diode D1, energy storage filter inductor L1 , the input capacitor C3 is connected between the input positive and negative bus bars, and the output capacitor C4 is connected between the output positive bus bar and the negative bus bar; the asymmetrical half-bridge inverter circuit 2 includes MOSFET switch tubes Q2 and Q3, and an output transformer T1, Current limiting inductor L2. The drain of the MOSFET switch Q2 is connected to the output positive bus of the BUCK circuit, the source of the MOSFET switch Q3 is connected to the output negative bus of the BUCK circuit, and one end of the primary side of the transformer T1 is connected to the source of the MOSFET Q2 and the MOSFET switch The drain of the tube Q3, the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com