Laser detection display for judging actual position of power knife switch

A technology of actual position and laser detection, applied in circuit breaker testing, testing of mechanical components, testing of machine/structural components, etc., can solve three-phase unbalance, operation personnel on duty violate switching operation regulations, and lack of strength and other problems, to achieve the effect of preventing misoperation accidents, pre-test judgment function and service life enhancement, and advanced and perfect instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

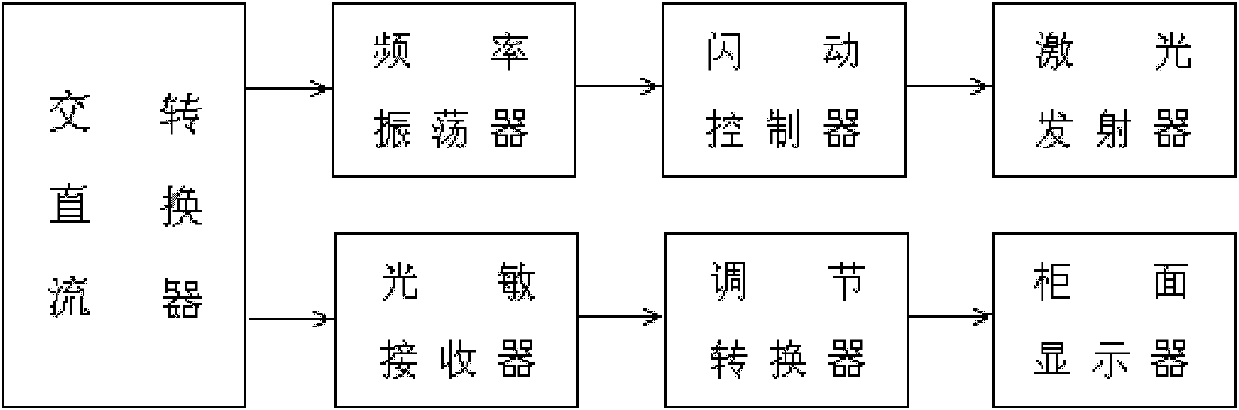

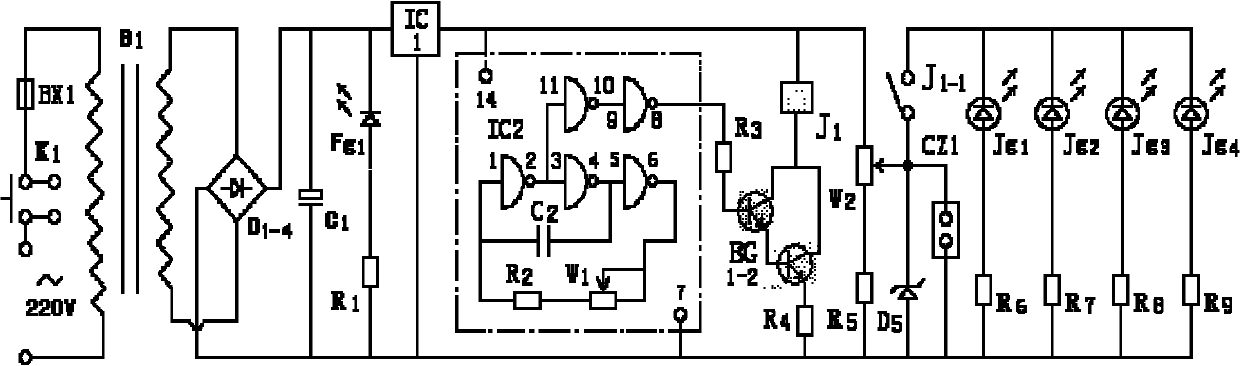

[0033] From figure 2 It can be seen from the figure that under the common power supply, the instrument is also divided into three parts: laser emission, photosensitive reception and display on the cabinet.

[0034] The first block consists of the frequency oscillator, the flash controller and the laser emitter, the laser source that forms the flash emission.

[0035] The second block includes a photosensitive receiver and an adjustment converter. This part completes the functions of laser penetration reception and display adjustment.

[0036] The third block is mainly the counter display, which presents the signals after laser emission, reception, and sorting, and informs the operator of the actual position of the current knife switch, so as to determine whether there is a fault.

[0037] The third block also has the function of use and test control, which can select the operating state of the instrument.

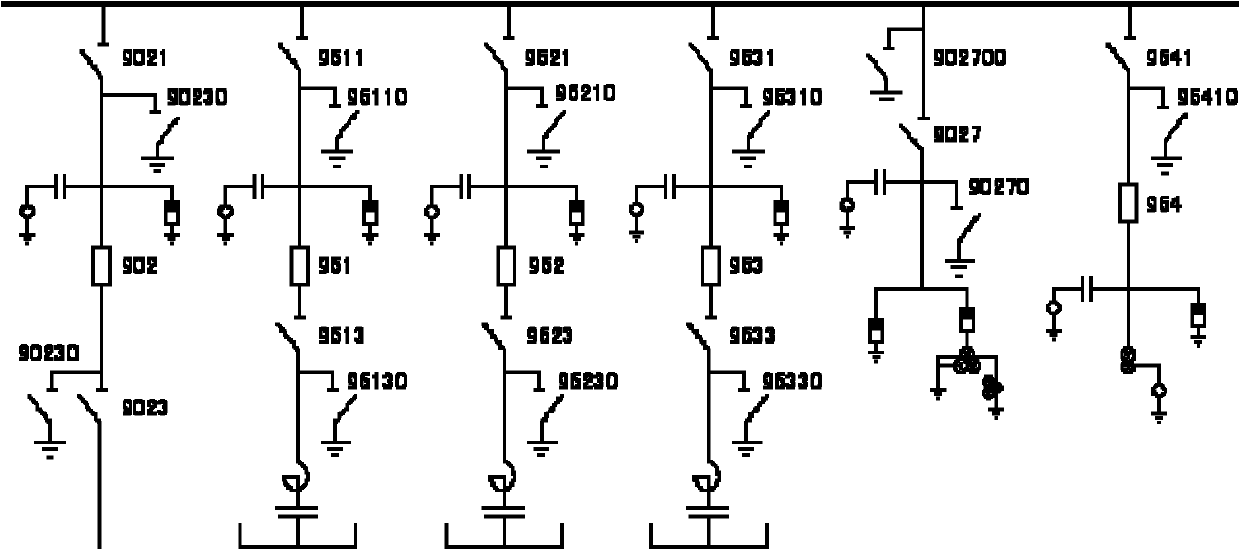

[0038] Figure 3-1As shown, the structure of the laser emission ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com