Alternating current (ac) motor stator core of compressor and wire embedding method thereof

A technology of alternating current motor and stator iron core, which is used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of large surface loss of iron core and tooth pulse vibration loss, decreased motor efficiency, low power factor, etc. Achieve the effect of reducing the excitation current, improving the power factor, and reducing the air gap coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

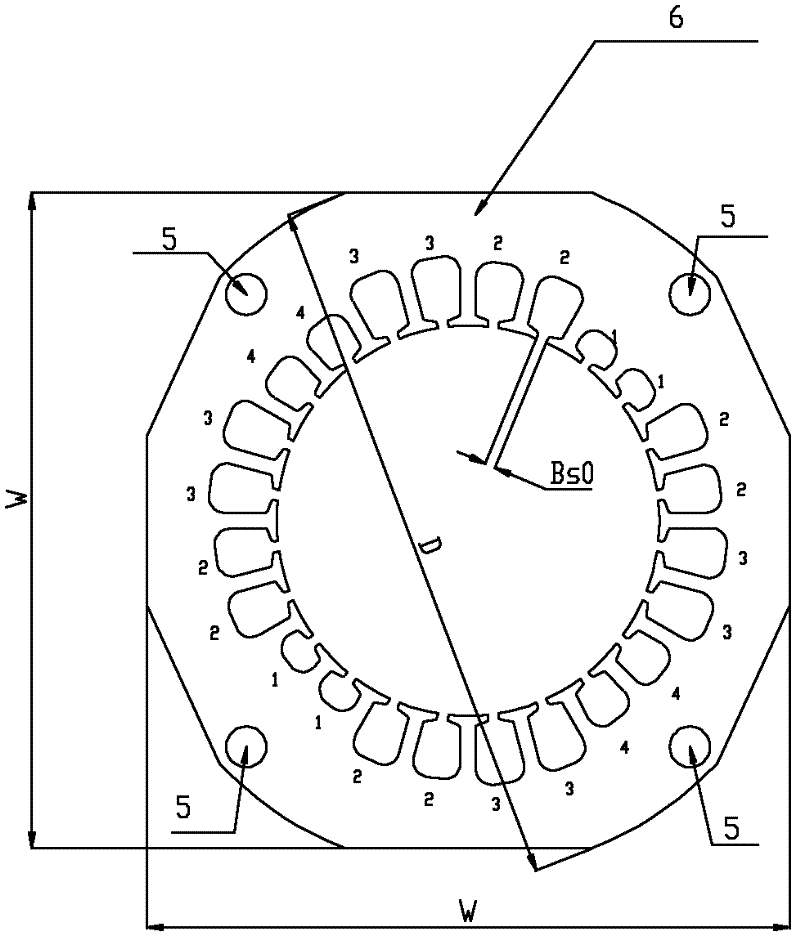

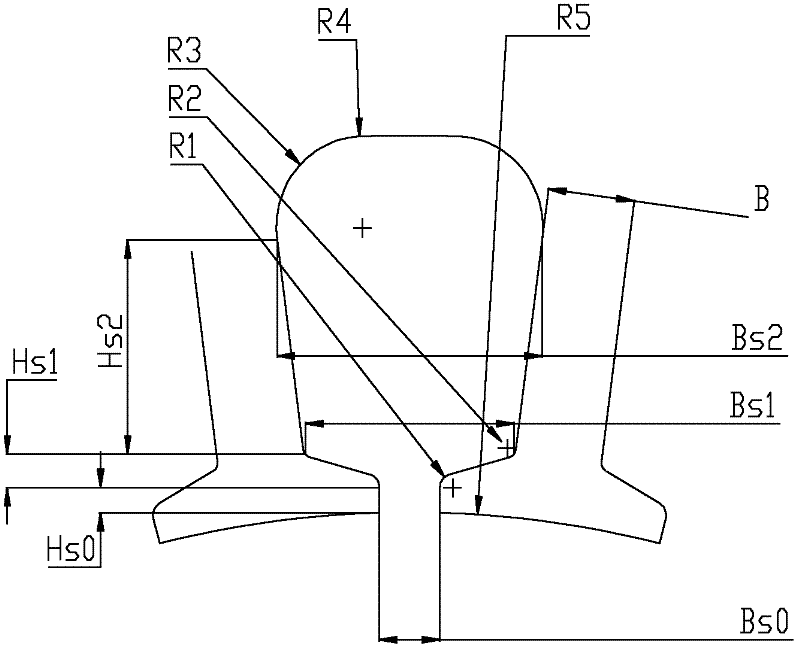

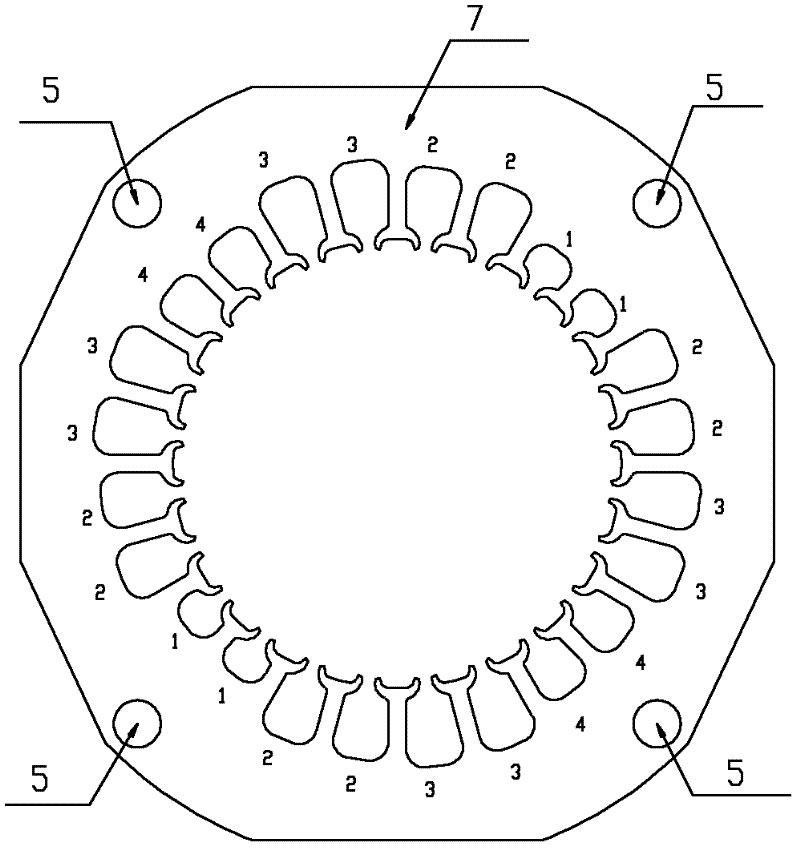

[0019] It is a single-phase asynchronous motor stator iron core used in a fully enclosed refrigeration compressor, including an iron core body 6. The iron core body is formed by lamination of punched sheets formed by stamping, and the thickness of each punched sheet is 0.5mm, the material of the punching sheet is 50WW470, the outer periphery of the iron core is a polygon including a circumscribed circular arc, including four sides of a regular quadrilateral, the width W of the regular quadrilateral is 84mm, and the circumscribed circle is passed between the four sides of the regular quadrilateral The circular arc is connected with the hypotenuse, and the diameter of the circumscribed circle is 90mm. There is a rotor hole in the middle of the iron core body. The diameter of the rotor hole (2R5) is 50mm. The axial length of the iron core body is 42.5mm. St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com