Microbacterium 18 for degrading unsymmetrical dimethylhydrazine and unsymmetrical dimethylhydrazine method therewith

A technology of unsymmetrical dimethylhydrazine and microbacteria, which is applied in the biological field and can solve problems such as high operating costs, high energy consumption, and immature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

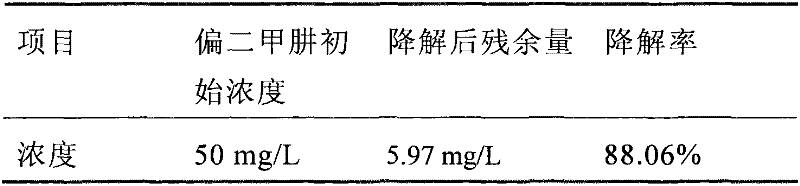

Embodiment 1

[0017] The present embodiment provides a kind of method utilizing Microbacterium M18 to degrade unsymmetrical dimethylhydrazine, comprising:

[0018] Seed culture: inoculate the strain of Microbacterium M18 on a slant culture medium, and culture at 24-37° C. for 12-30 hours to obtain a slant culture. The above slant medium consists of: tryptone 1-15g / L, malt extract 1-15g / L, bacto-peptone 1-15g / L and agar 15g / L.

[0019] Take the well-grown slant culture and inoculate it into a 250mL Erlenmeyer flask containing 50-100mL of seed medium. Under the condition that the rotational speed of the shake flask is 150-200 r / min and the culture temperature is 28-37 DEG C, culture is carried out for 12-30 hours to obtain the seed culture liquid. The composition of the above-mentioned seed medium: 1-15 g / L of tryptone, 1-15 g / L of malt extract and 1-15 g / L of bacto-peptone.

[0020] Degradation of unsymmetrical dimethylhydrazine: Inoculate 15.78mL of seed liquid into a 1000mL Erlenmeyer fl...

Embodiment 2

[0023] Seed culture: inoculate the strain of Microbacterium M18 on a slant medium composed of tryptone, malt extract, bacto-peptone, and agar, and cultivate it at 27°C for 24 hours to obtain a slant culture; the composition of the above slant medium : tryptone 3g / L, malt extract 3g / L, bacto-peptone 5g / L and agar 15g / L.

[0024] Take the well-grown slant culture and inoculate it into a 250mL Erlenmeyer flask containing 110mL of seed medium, and cultivate it for 18 hours under the conditions of a shaker flask rotation speed of 200r / min and a culture temperature of 30°C; the composition of the above seed medium: Peptone 3g / L, malt extract 3g / L and bacto-peptone 5g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com