Movable static var compensator and direct current ice-melting device and realization method thereof

A technology of static reactive power compensation and DC ice melting, applied in reactive power adjustment/elimination/compensation, overhead installation, cable installation, etc., which can solve the problems of large volume of air-core reactors, large magnetic leakage, and difficulty in device movement. , to achieve the effect of convenient and fast movement, simple installation and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

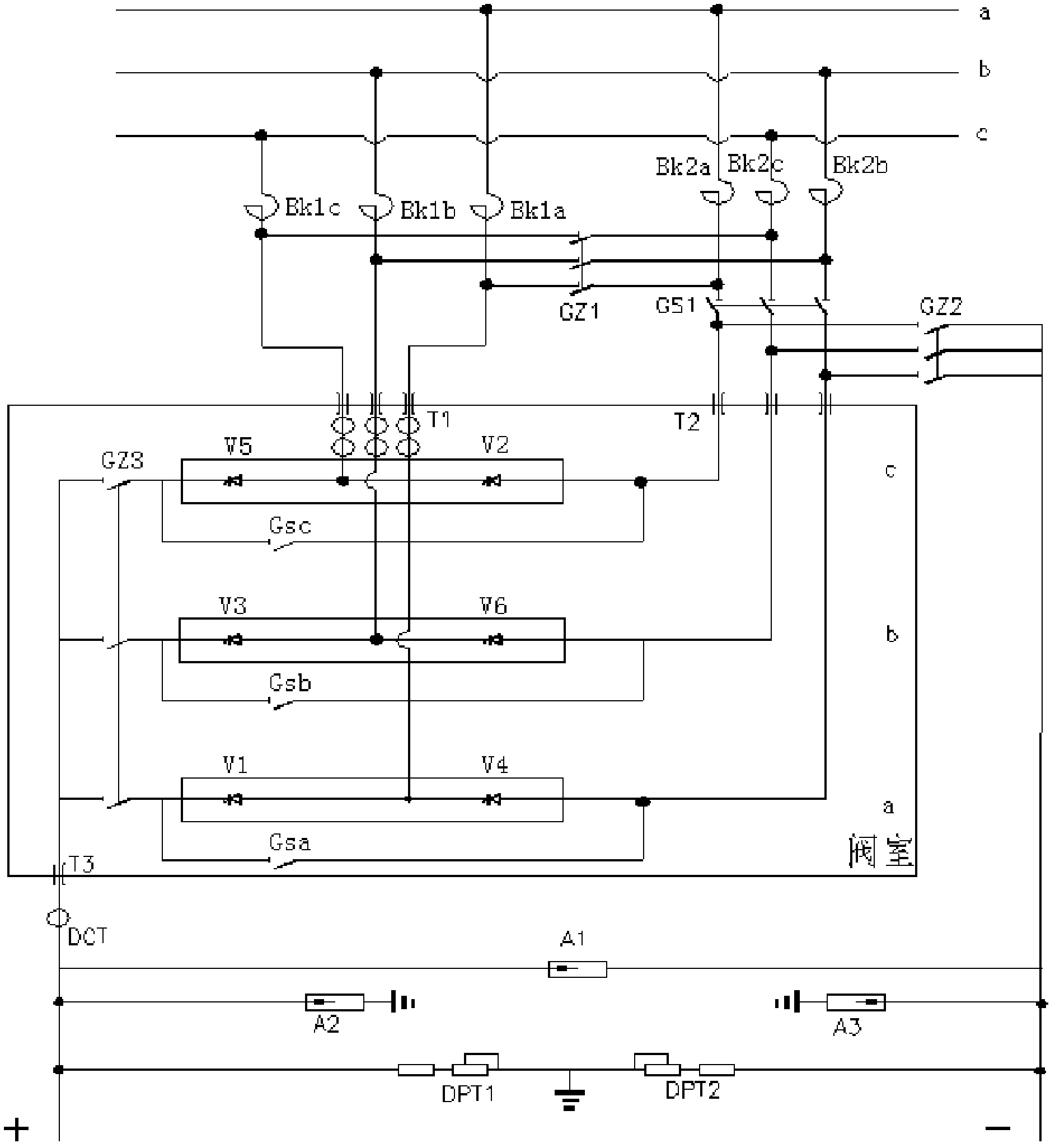

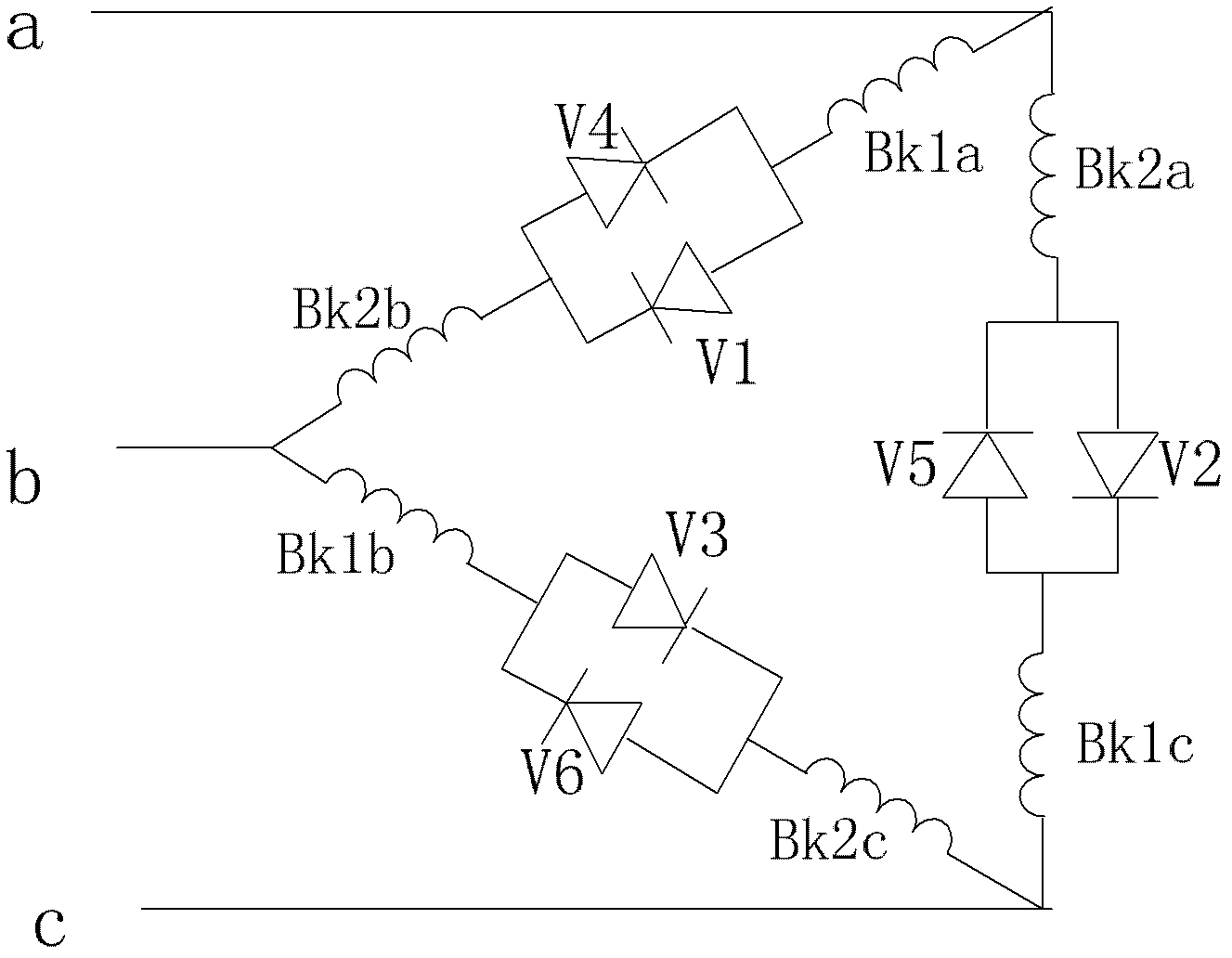

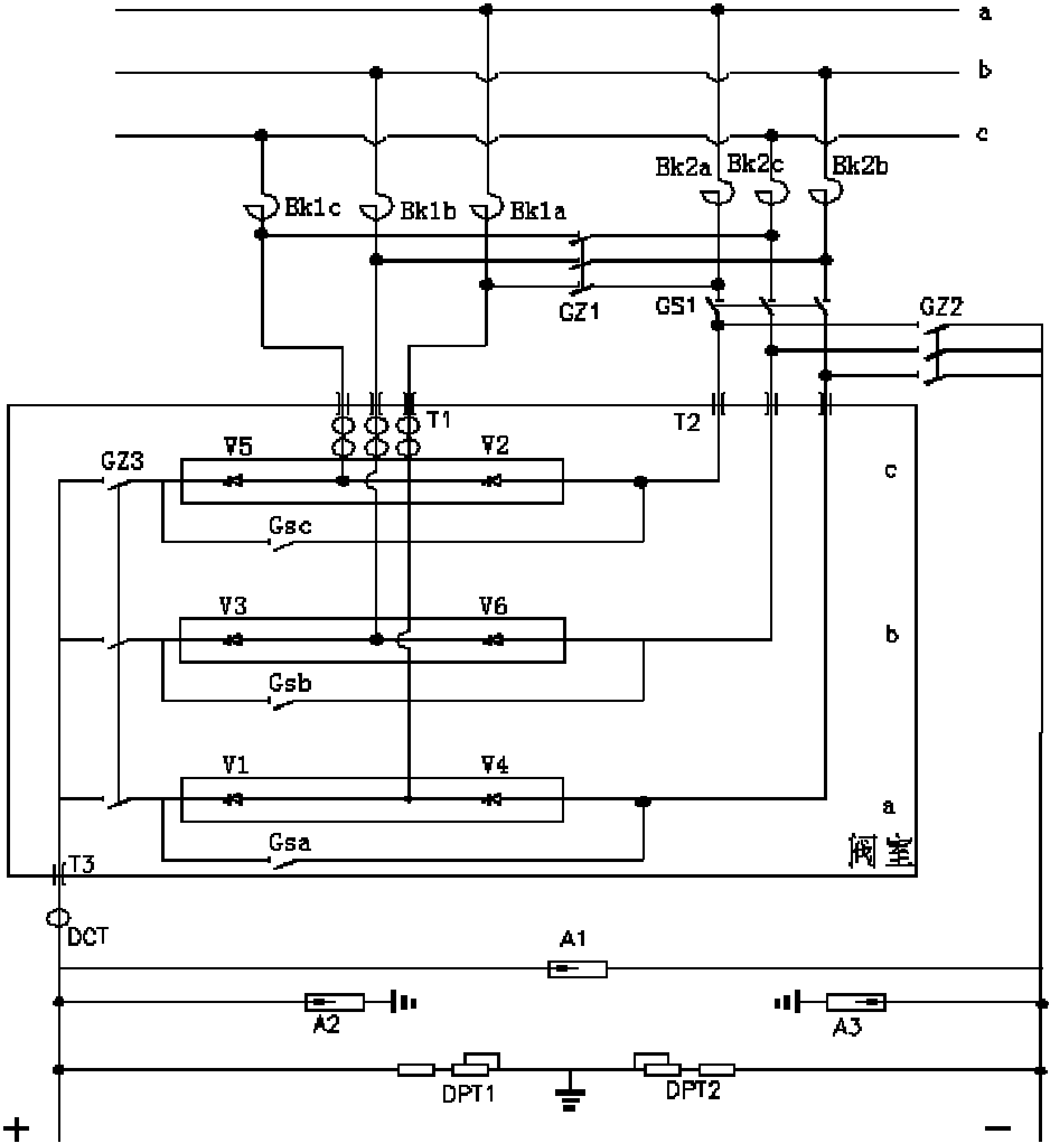

[0024] Such as figure 1 As shown, the primary side of the device in this embodiment includes a thyristor converter, an iron core reactor, an isolating switch and a surge arrester; wherein the thyristor converter doubles as a thyristor-controlled reactor type TCR valve group, and the iron core reactor can be used in DC It is used as a commutation reactor in the ice-melting mode, and as a phase-controlled reactor of the thyristor-controlled reactor type TCR in the static var compensation mode, and both the thyristor converter and the core reactor are detachable structures. Isolation switches are set between each detachable structure, the line knife switch is operated sequentially, and the thyristor converter and iron core reactor are disassembled and reorganized to form different topological structures. Among them, the ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com