Online flaw detection process of pipeline forming and machining process

A molding processing and pipeline technology, which is applied in metal processing, metal processing equipment, measuring devices, etc., can solve the problem that whether there are defects on the surface cannot be confirmed, and achieve the effect of reducing defective products and reducing the number of occurrences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

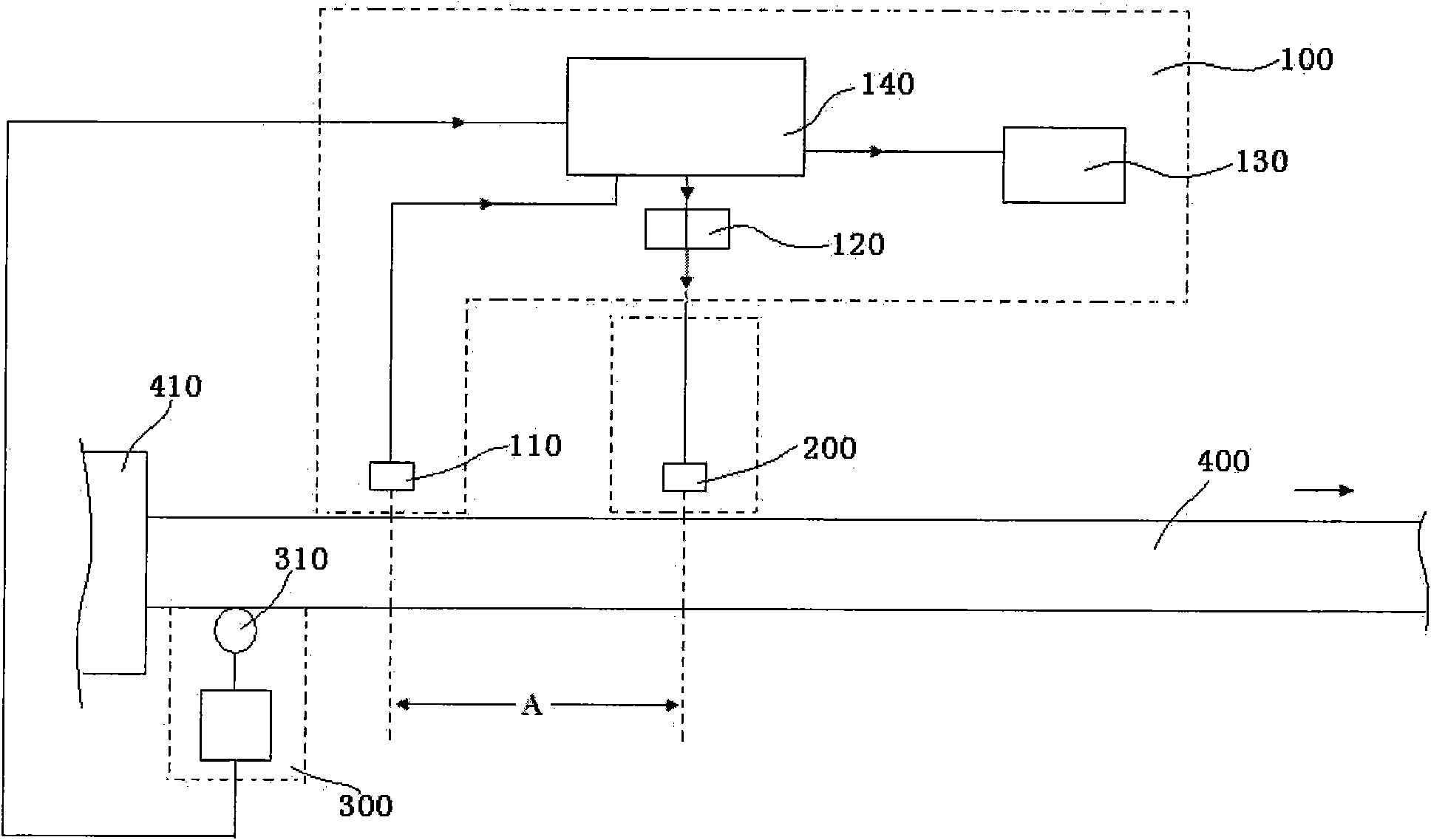

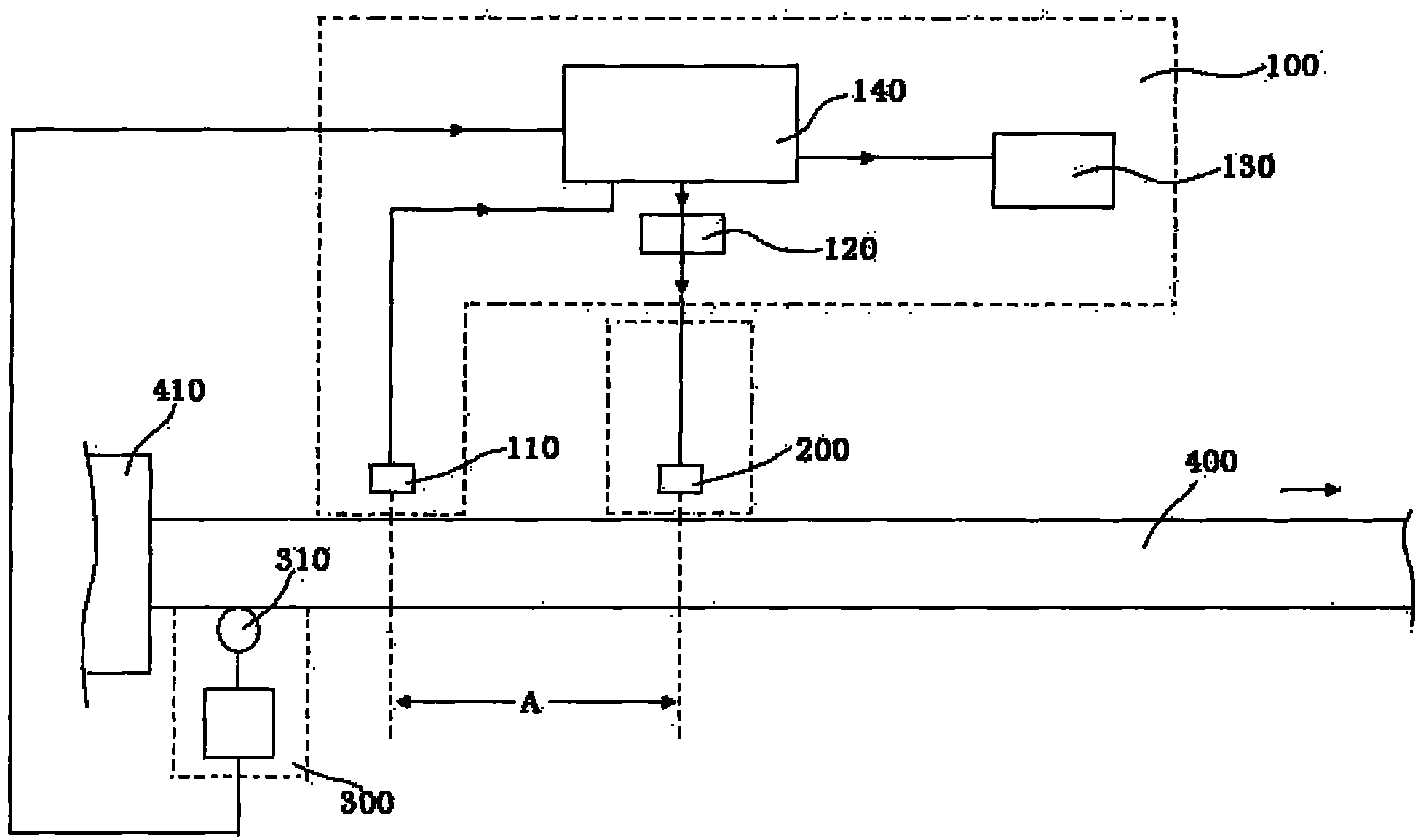

[0010] refer to figure 1 Shown: the flaw detection detection process in the forming process, which is to add a high temperature resistant flaw detection head 110 of a through-type eddy current flaw detector 100 and a counting device 200 after the discharge port of the forming processing equipment, the high temperature resistant flaw detection head 110 and the counting device There is a distance A between the devices 200, and a driving device 120 and an alarm device 130 are added to the penetrating eddy current flaw detector 100. The alarm device 130 is connected, the driving device 120 is connected to the counting device 200 , the signal output end of the high temperature resistant flaw detection head 110 and the length measuring device 300 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com