Method for detecting singular area in five-axis machining

A technology of singular area and detection method, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as low versatility, cumbersome library building process, and can not fully reflect the sudden change of machine tool axis speed, etc. achieve accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings.

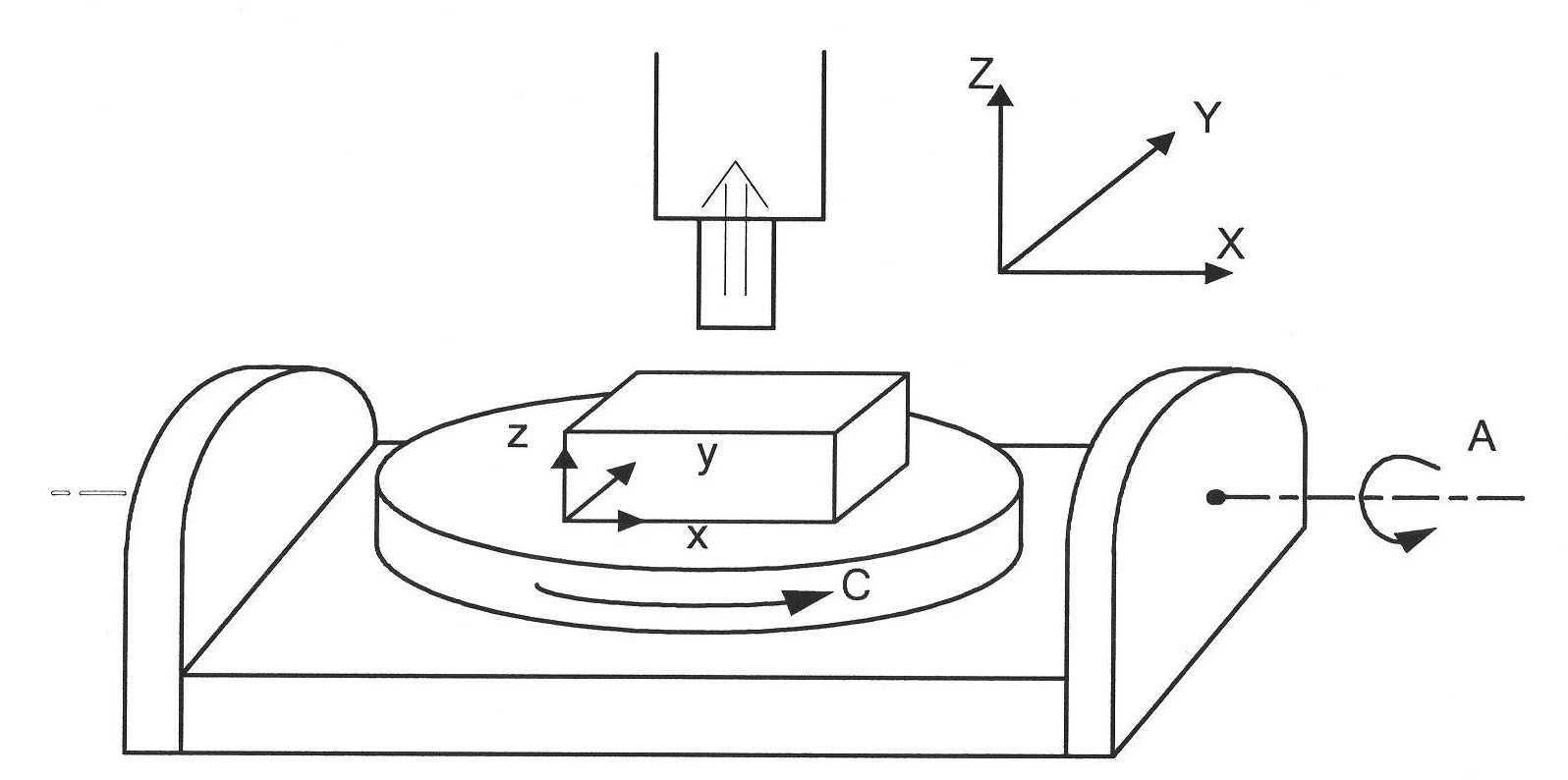

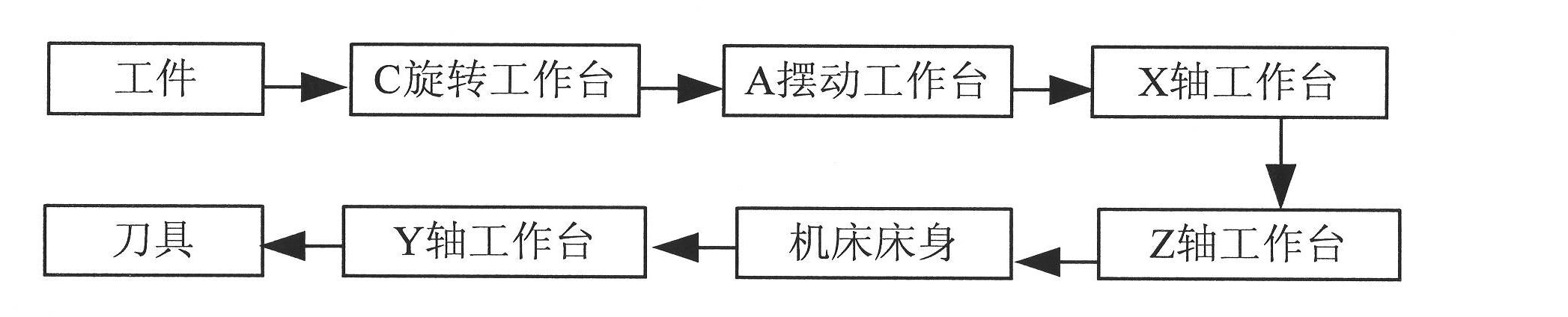

[0029] In order to accurately detect the boundary range of the singular area, this embodiment takes the AC double turntable five-axis machine tool as the research object, combines the movement variation of each axis during the machining process with the Jacobian matrix of the five-axis machine tool, and judges the Jacobian matrix Whether the condition number is too large, and then get the state of the Jacobian matrix, so as to detect whether the current processing position has entered or left the singular region. Such as figure 1 Shown is a structural schematic diagram of the AC double turntable five-axis machine tool used in the method of the present invention.

[0030] The inventive method step is as follows:

[0031] Establish the kinematic transformation relationship of the AC double turntable five-axis machine tool, and determine the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com