Manual bamboo fence baffle knitting machine

A technology for weaving machines and bamboo fences, applied in mechanical equipment, sugarcane machining and other directions, can solve the problems of high raw material specifications, size requirements, certain difficulties in operation, and high manufacturing costs, and achieve low manufacturing costs, consistent specifications, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

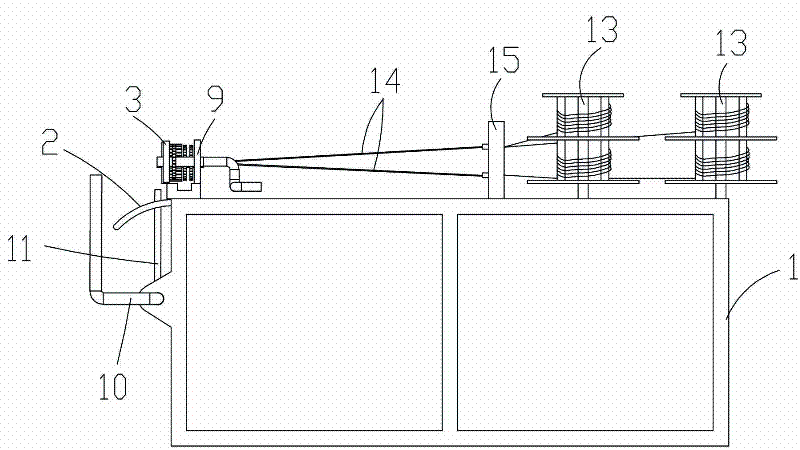

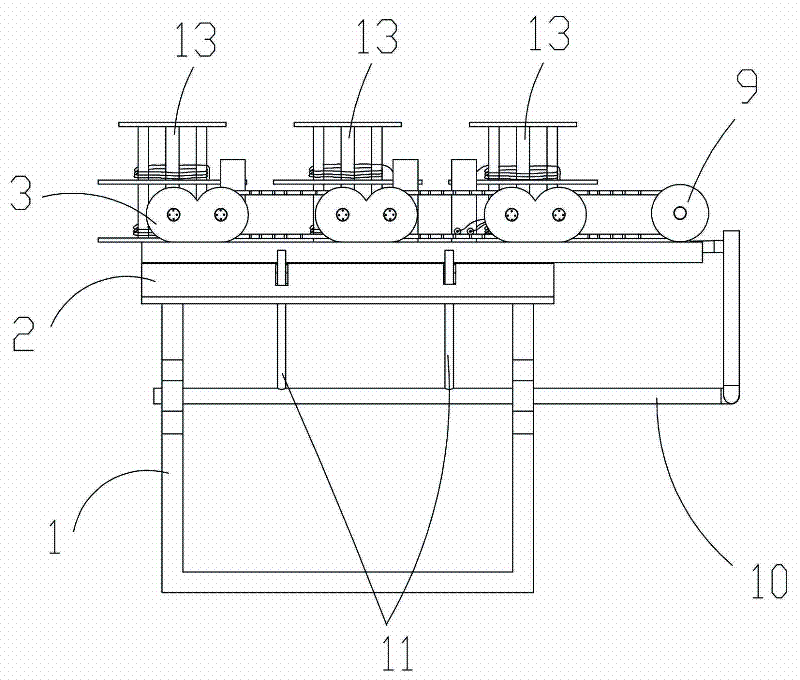

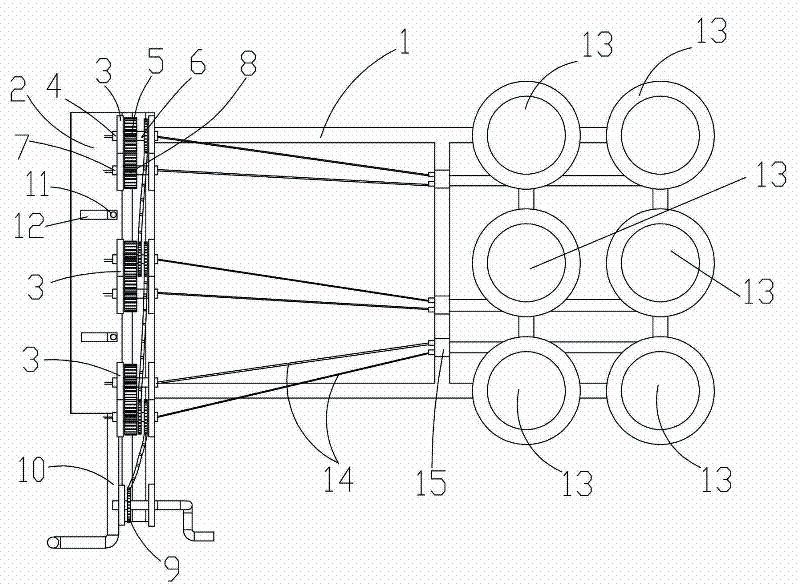

[0014] see figure 1 , figure 2 , image 3 and Figure 4 A kind of manual bamboo fence knitting machine shown, comprises frame 1, is located at the knitting mechanism on the frame front end, is located at the curved slide plate 2 on the frame front end, is located at the material dialing mechanism in front of the frame And the wire turntable assembly located on the rear of the rack;

[0015] The braiding mechanism includes three groups of side-by-side twisters, each group of twisters is composed of a low seat 3 positioned and connected to the front end of the frame, an active twisting shaft 4 cooperating with the low seat, and a coordinating connection with the active The driving gear 5 and the double sprocket 6 on the twisted wire shaft, the driven twisted wire shaft 7 connected on the low seat and the driven gear 8 matched on the driven twisted wire shaft are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com