Water-cooling anti-coking instilling and nitrogen blocking removing device of double-row rare earth gas carburizing furnace

A gas carburizing and anti-coking technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of increasing the labor intensity of operators, affecting the quality of gear carburizing, and destroying the carburizing atmosphere in the furnace. , to achieve the effect of reducing labor intensity, improving quality and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

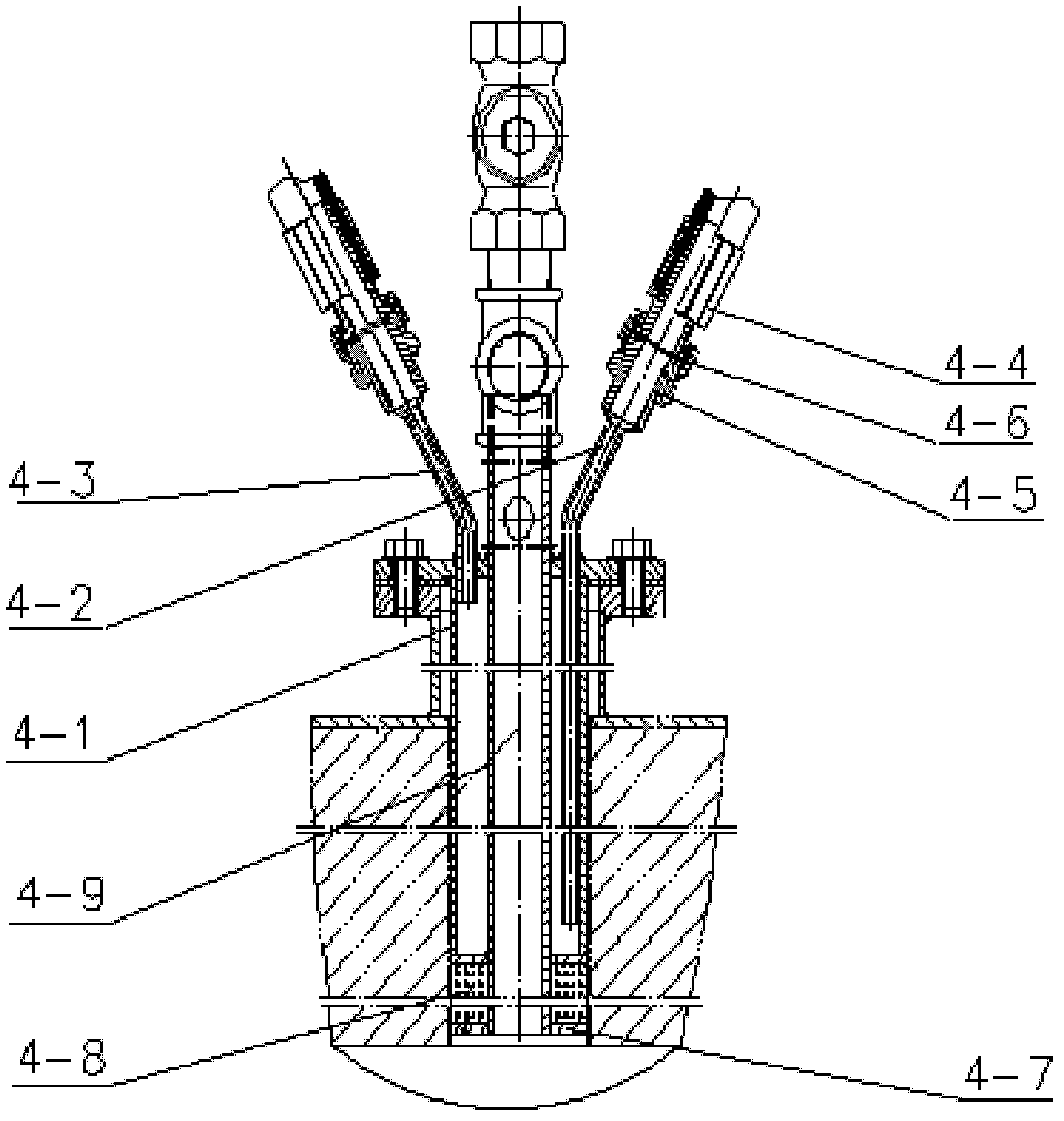

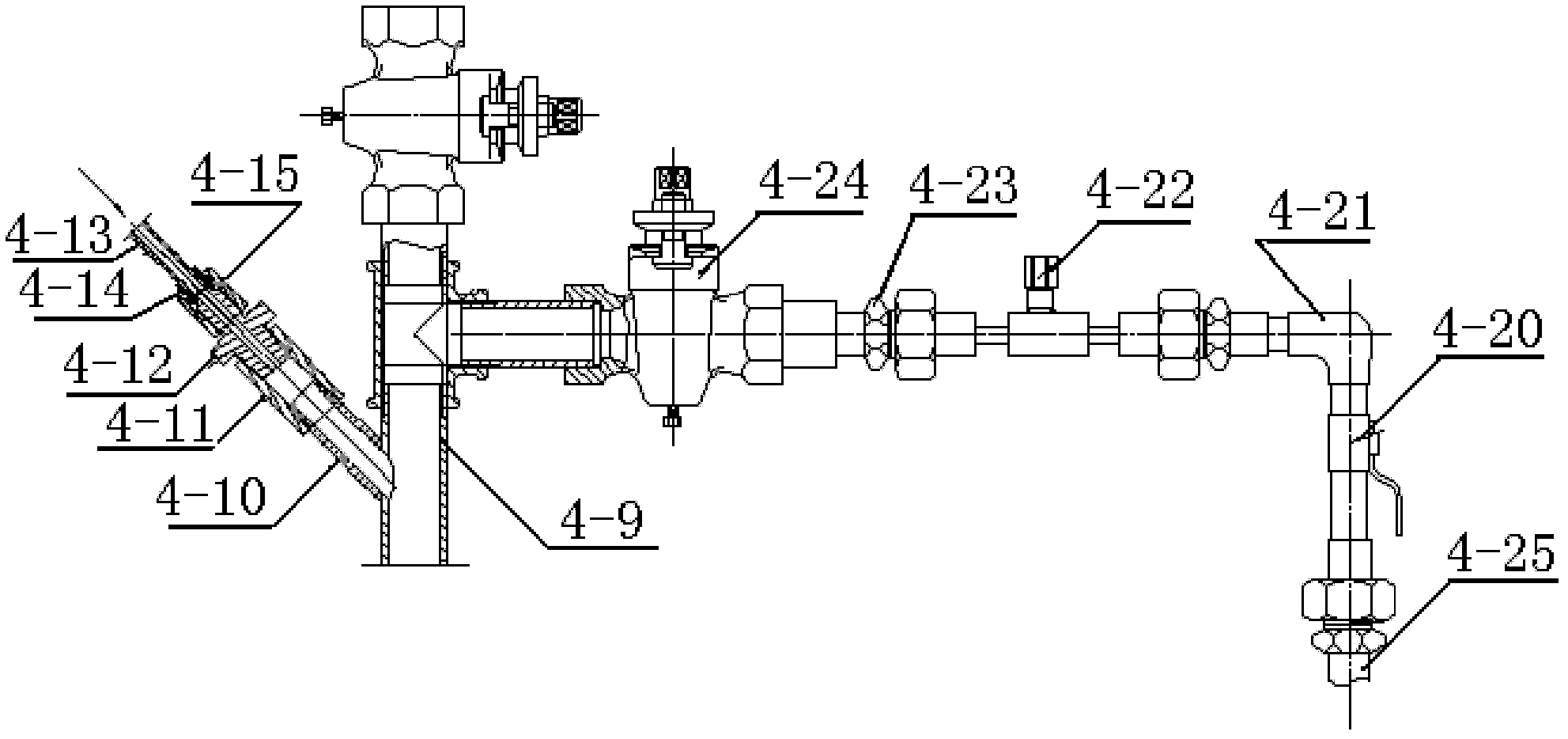

[0009] Specific implementation mode one: combine figure 1 , 2 , 3 Describe this embodiment. This embodiment consists of water-cooled anti-coking infusion and nitrogen de-plugging device,

[0010] The water-cooled anti-coking infusion device consists of a cooling water jacket 4-1, a cooling water inlet pipe 4-2, a cooling water outlet pipe 4-3, a buckle-type steel wire braided high-pressure rubber hose 4-4, and a straight-through pipe joint 4- 5. It is composed of O-shaped sealing ring 4-6, heat-resistant steel baffle plate 4-7, insulation layer 4-8 and dripping main pipe 4-9. The lower end of the cooling water inlet pipe 4-2 is located at the bottom of the cooling water jacket 4-1 right side, and the lower end of the cooling water outlet pipe 4-3 is located at the top of the cooling water jacket 4-1 left side. The upper ends of the cooling water inlet pipe 4-2 and the cooling water outlet pipe 4-3 are welded to the straight-through pipe joint 4-5, and an O-shaped seal is pr...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 The present embodiment will be described. The insulation layer 4-8 of this embodiment is made of aluminum silicate ceramic fiber material with a thickness of 60mm.

specific Embodiment approach 3

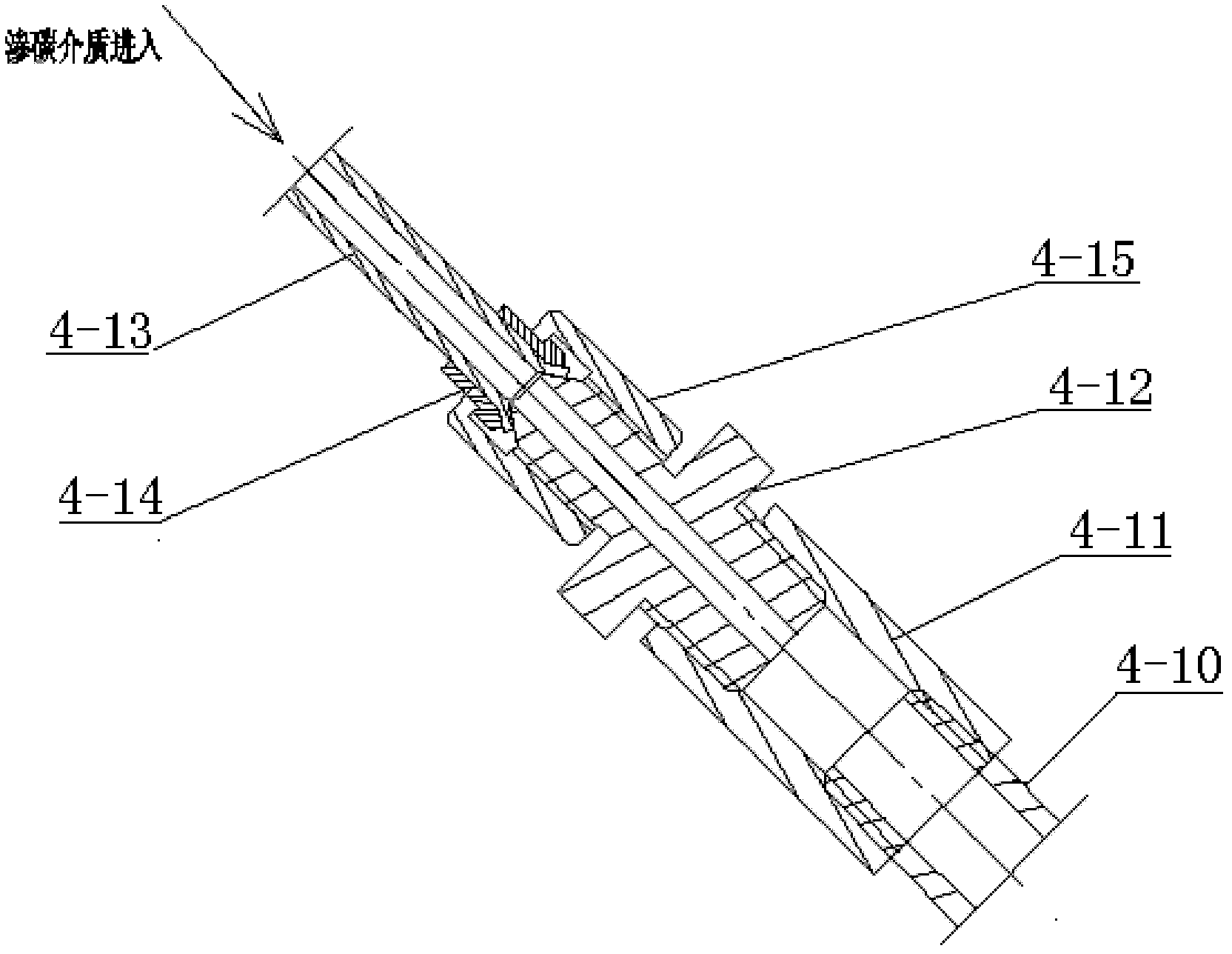

[0015] Specific implementation mode three: combination figure 2 , 3 The present embodiment will be described. The carburizing medium dripping pipe 4-13 that is punched into the bell mouth of the present embodiment adopts a red copper tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com