Lorry spiral bevel gear double-row rare earth continuous gas carburization heat treatment equipment

A technology for heat treatment equipment and trucks, applied in coating, metal material coating technology, solid diffusion coating, etc., can solve the problem of poor anti-adhesive wear performance of gears, low surface hardness of carburized gears, and easy blockage of drip tubes To achieve the effect of increasing the carburizing speed, avoiding the out-of-tolerance level of retained austenite, and shortening the pushing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

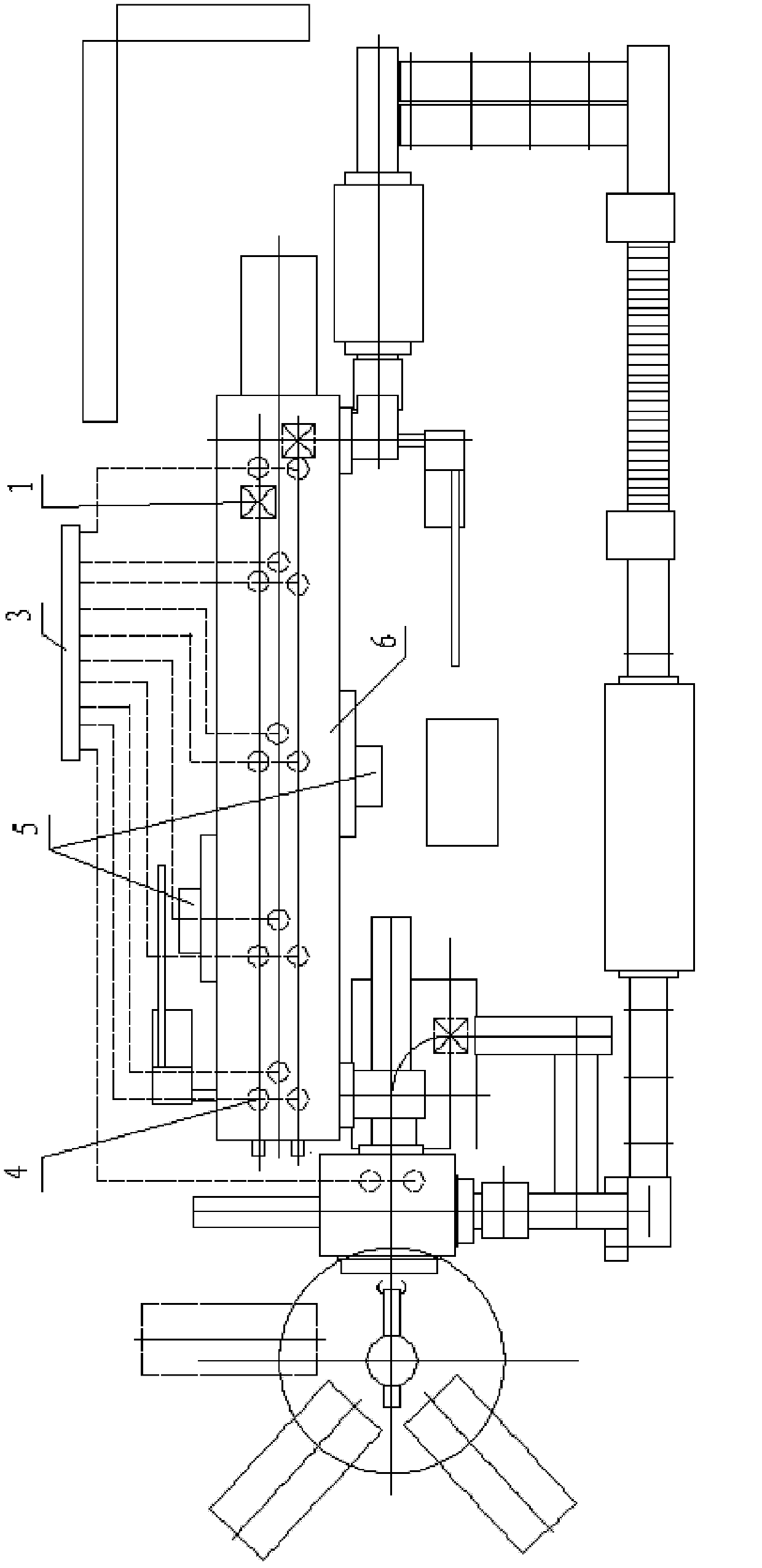

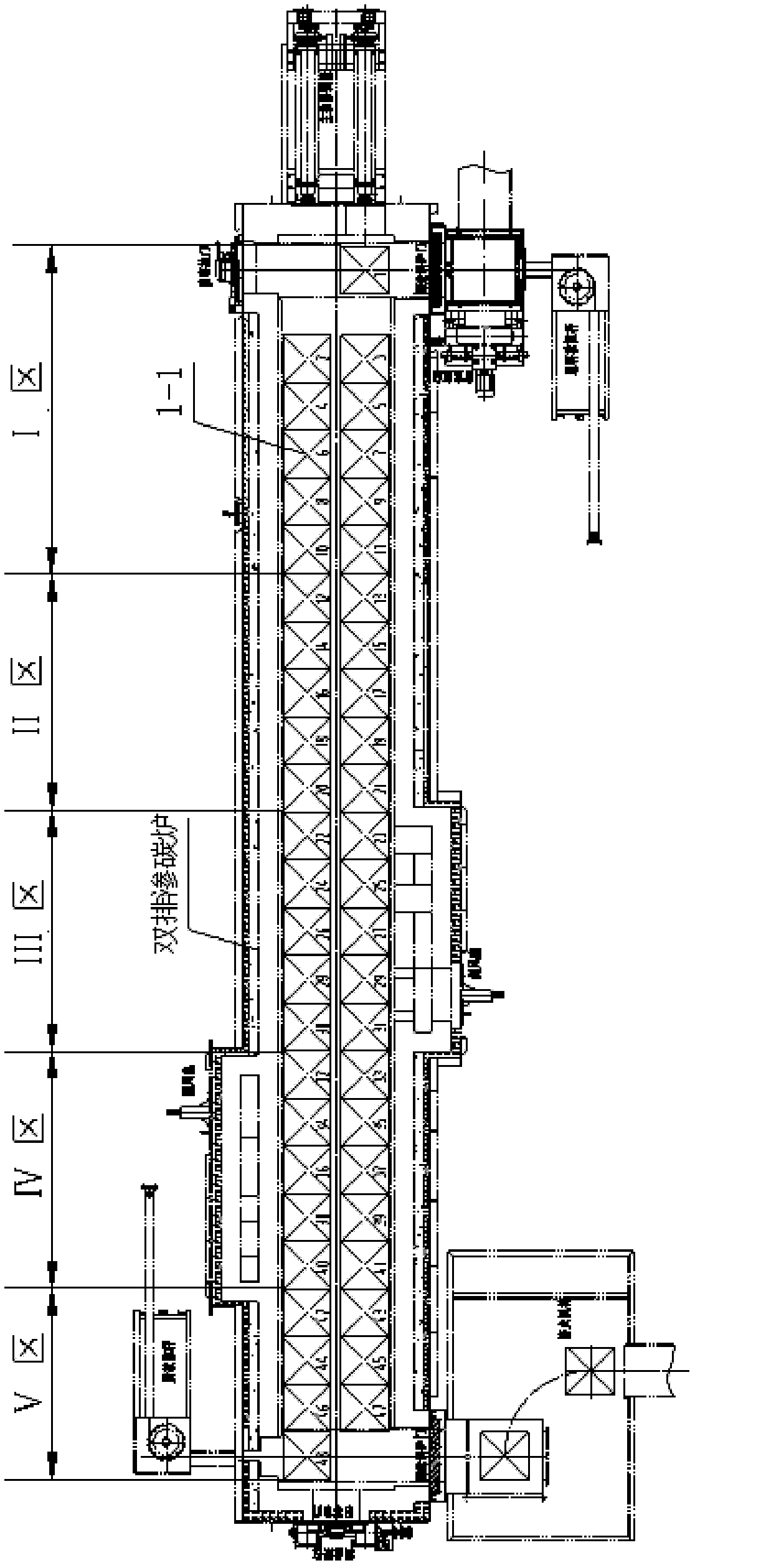

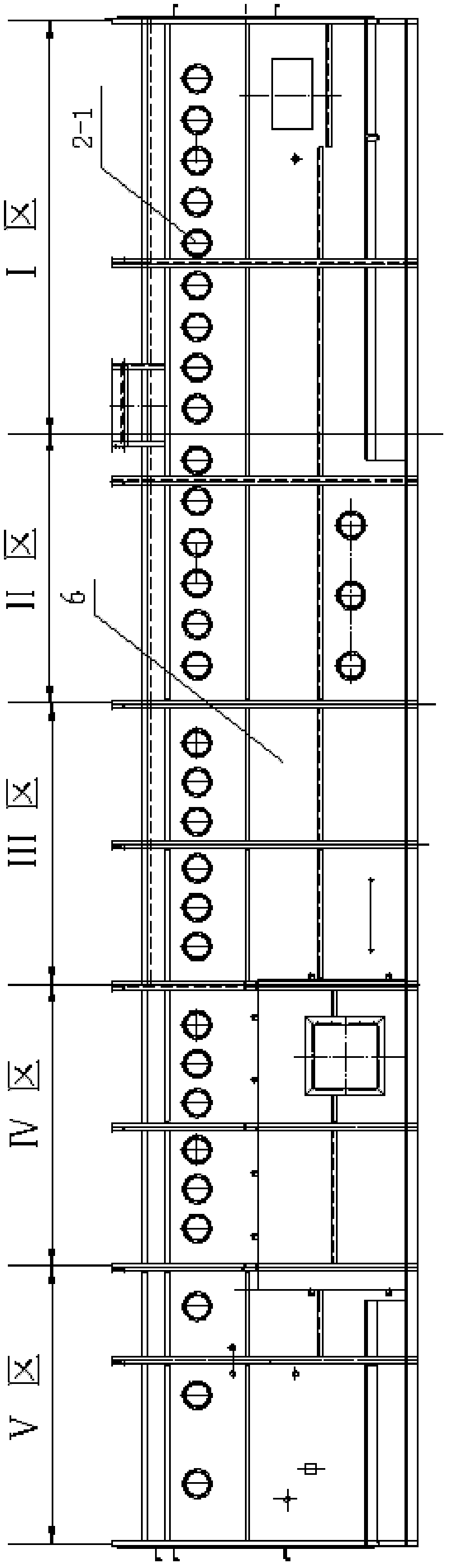

[0013] Specific implementation mode one: combine Figure 1 to Figure 17 The present embodiment will be described. This embodiment consists of a material pan 1, a heating device 2, a carburizing medium flow plate 3, a carburizing furnace water cooling anti-coking drip and nitrogen deplugging device 4, a direct-connected side fan 5 and a furnace body 6. The material pan 1 And the heating device 2 is set in the furnace body 6, the carburizing medium flow plate 3 is set outside the furnace body 6, the carburizing medium flow plate 3 is connected with the furnace body 6, and the carburizing furnace water cooling anti-coking instillation and nitrogen deplugging device 4 is connected with the furnace body 6, and the direct-connected side fan 5 is arranged on the side wall of the furnace body 6.

[0014] The described material tray 1 is calculated by the material tray 1-1 with 48 trays set in double rows, 10 trays are set in the heating zone, 10 trays are set in the soaking zone, 10 ...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 , image 3 The present embodiment will be described. The heating power of the heating zone (I zone) described in this embodiment is 200KW, and the heating power of the soaking zone (II zone) is also 200KW, which increases the heating power of the II section from the original 100KW to 200KW. The position of the temperature control point and the carbon potential control point is improved, which increases the heating speed of the workpiece, speeds up the recovery of the carburizing atmosphere and carbon potential in the furnace, and the recovery time of the carburizing atmosphere and carbon potential in each pushing cycle The original 15-20 minutes is shortened to 6-10 minutes, so that the position of the last two trays in the II section can evolve into a carburizing area, which relatively increases the carburizing area; the heating power of the carburizing area (III area) 100KW, 6 radiant heating tubes are arranged,...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination Figure 4 , Figure 5 , Figure 9 The present embodiment will be described. The welded tee pipe joint 3-45 described in this embodiment consists of a steel pipe 3-45-1, a connecting pipe 3-45-2, a nut 3-45-3, an O-ring seal 3-45-4, and a type A The three-way joint body 3-45-5 is composed of one end of the connecting pipe 3-45-2 welded with the steel pipe 3-45-1, and the other end of the connecting pipe 3-45-2 is connected with the A-type tee joint body 3-45-5 An O-ring 3-45-4 is arranged between adjacent ends of the pipe, and the other end of the connecting pipe 3-45-2 is connected with the A-type tee joint body 3-45-5 by a nut 3-45-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com