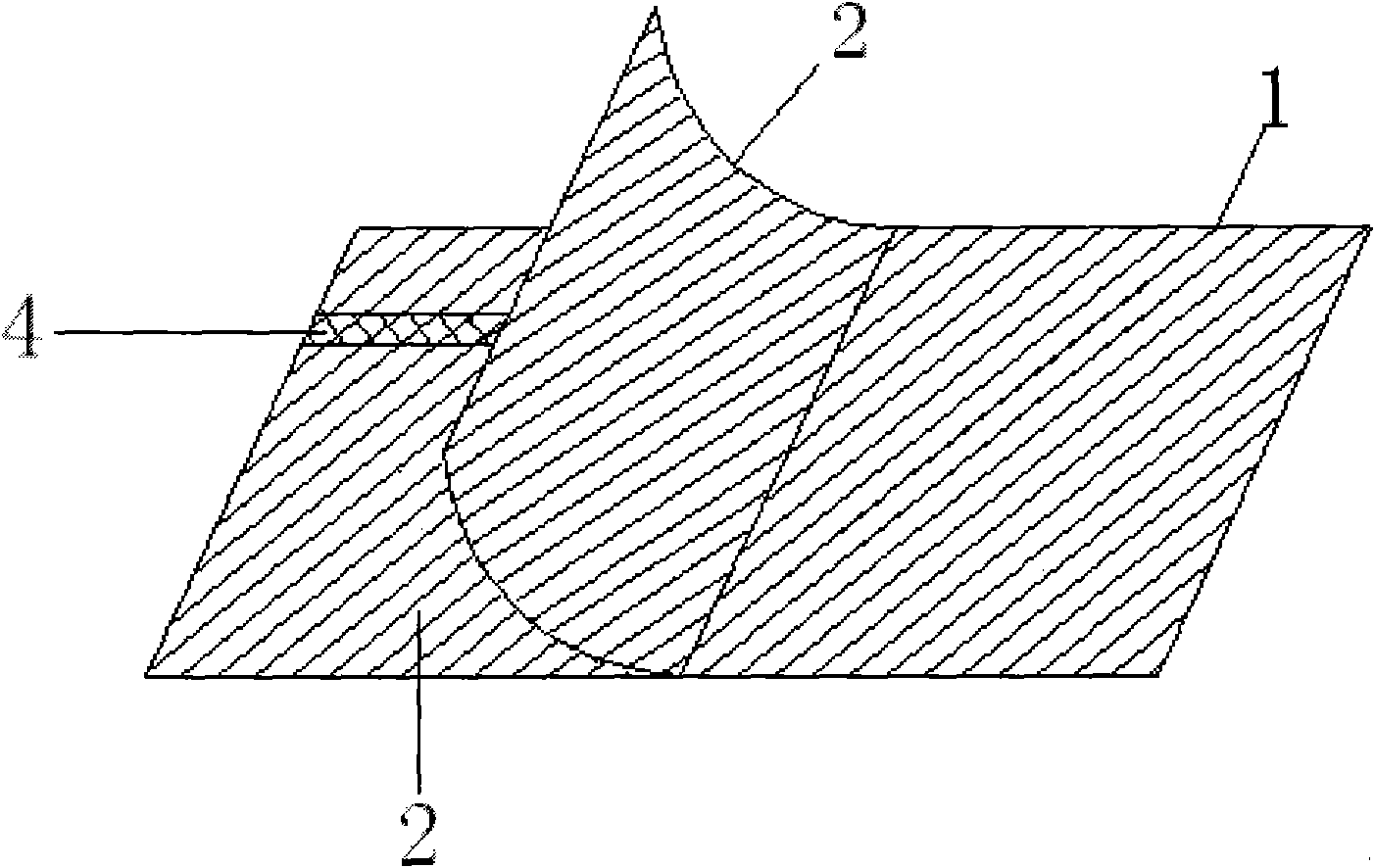

Anti-counterfeiting paper and manufacture method thereof

A manufacturing method and technology of anti-counterfeit paper, applied in chemical instruments and methods, papermaking, paper, etc., can solve the problems of poor printing performance, anti-counterfeit fiber falling off, easy forgery of anti-counterfeiting paper, etc., and achieve the effect of easy observation and detection, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

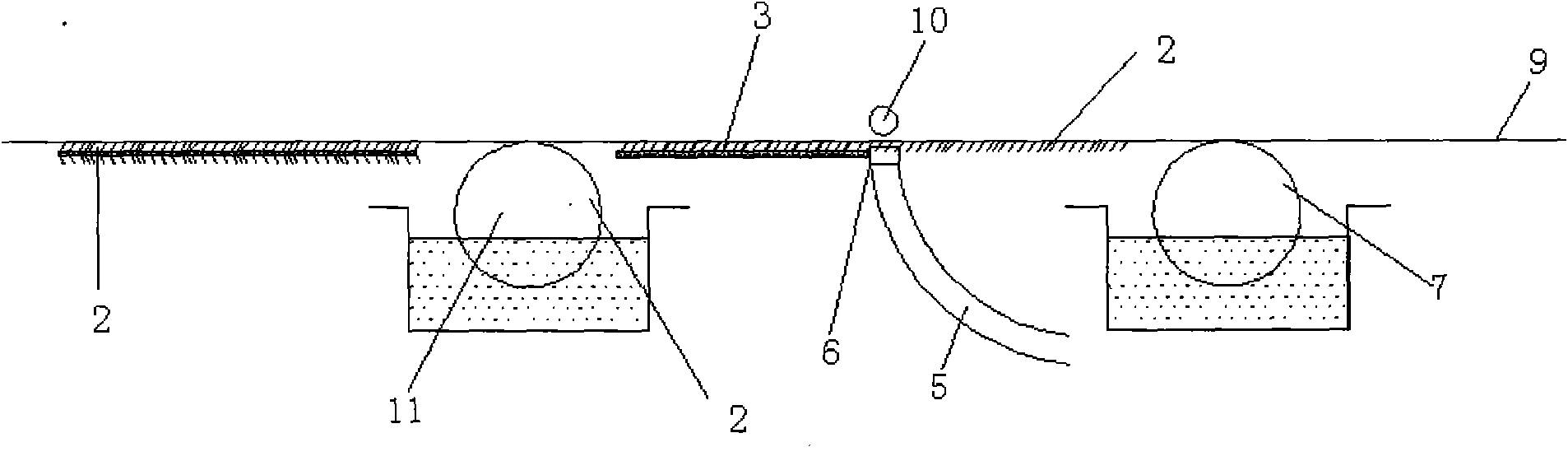

[0036] In this embodiment, during the copying process, a square plastic sheet with a side length of 0.3mm and a thickness of 0.01mm is dispersed in water at a concentration of 0.001% by mass to form a uniform dispersion system, and passes through a release tube with a diameter of 0.8mm. According to the flow rate of 600ml / min, it is applied to the surface of the first wet paper sheet through the discharge port, and the second wet paper sheet is formed by vacuum dehydration. When the second wet paper sheet is compounded, it is clamped in the middle of the paper sheet. In the final finished paper, the sheet material is distributed in the middle of the paper in the form of bands.

Embodiment 2

[0038] In this embodiment, during the copying step, the circular plastic sheet with an area of 5.0 mm and a thickness of 0.02 mm is dispersed in water to form a uniform dispersion system at a concentration of 0.07% by mass percentage, and the anti-counterfeiting material dispersion is released through the discharge port The flow is sent to the surface of the first wet paper sheet, and the distance between the release port and the fourdrinier is 1.5cm, and the second wet paper sheet is formed by vacuum dehydration, and the sheet material is attached to the surface of the second wet paper sheet, and on the other first wet It is clamped in the middle of the paper when it is combined with the second wet paper. In the finished paper finally obtained, the sheet-like material is distributed in the middle of the paper in a band shape, and the width of the distribution band is between 1.5 mm and 2 mm.

Embodiment 3

[0040] In this embodiment, during the copying step, the anti-counterfeiting fiber with a length of 3mm and a thickness of 1.2dtex is dispersed in water at a concentration of 0.03% by mass to form a uniform dispersion system, and the diameter is passed through a release tube of 8mm at a rate of 300ml / min. The flow rate is applied to the surface of the first wet paper sheet through the release port, and the distance between the discharge port and the fourdrinier is 0.5cm, and the second wet paper sheet is formed through vacuum dehydration. The anti-counterfeiting fiber is attached to the surface of the second wet paper sheet, and the When the first wet paper sheet and the second wet paper sheet are compounded, they are sandwiched between the paper sheets. In the final finished paper, the anti-counterfeiting fibers are distributed in the middle of the paper in a band shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com