Anti-counterfeiting transfer paper with small fisheye effect and production method of anti-counterfeiting transfer paper with small fisheye effect

A technology for transferring paper and crystal dots, applied in special paper, paper, papermaking, etc., can solve the problem of reducing the anti-counterfeiting effect, and achieve the effect of avoiding easy copying, enhancing the anti-counterfeiting effect, and anti-counterfeiting inquiry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

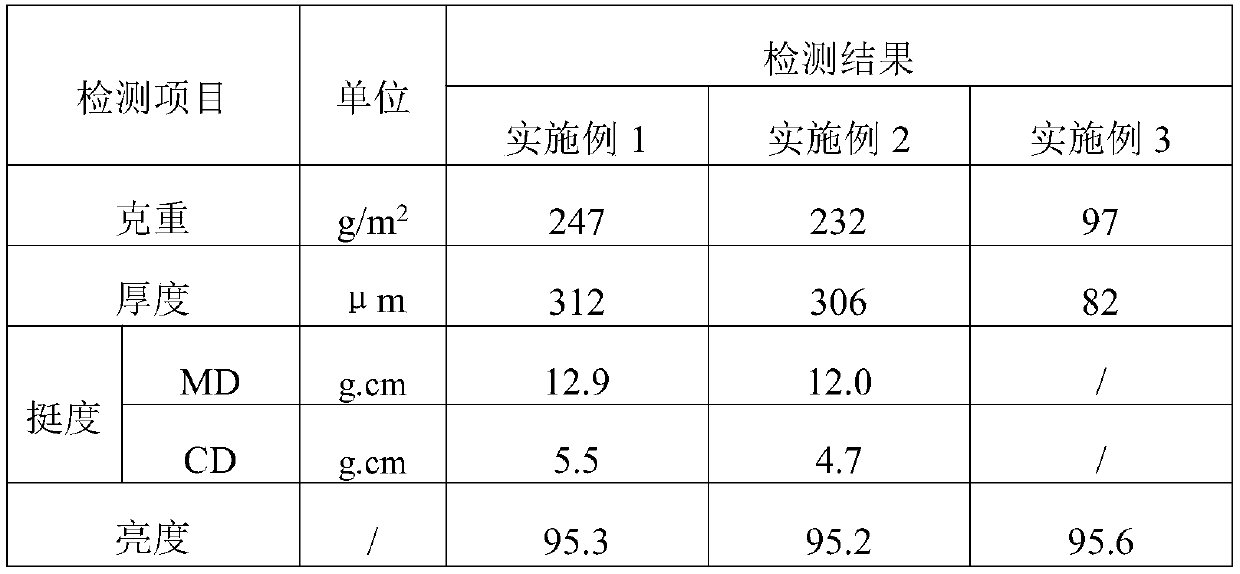

Embodiment 1

[0026] The preparation method of the anti-counterfeiting transfer paper with small crystal point effect comprises the following steps:

[0027] (1) Prepare transfer coating: take modified acrylate polymer as base resin and add 0.1% anti-counterfeiting material to prepare transfer coating, solid content 25%;

[0028] (2) Coating: adopt single-sided one-time coating method, use 110 wire mesh roller to coat the transfer coating on the PET film, center the edge when coating, control the width of the edge on one side to be 0.2mm, dry coat The amount is 1.45g / m 2 ;

[0029] (3) Molding: temperature 165°C, pressure 0.32Mpa, speed 60m / min, press the laser pattern, the pattern is clear and translucent;

[0030] (4) Aluminum plating: vacuum aluminum plating is carried out on the transfer layer on a vacuum aluminum plating machine under a vacuum degree of 0.2Pa and a temperature of 140°C. The thickness of the aluminum plating layer is aluminum coating;

[0031] (5) Composite: 7.5g / m...

Embodiment 2

[0035] The preparation method of the anti-counterfeiting transfer paper with small crystal point effect comprises the following steps:

[0036] (1) Prepare transfer coating: take modified acrylate polymer as base resin and add 0.3% anti-counterfeiting material to prepare transfer coating, solid content 18%;

[0037] (2) Coating: adopt single-sided one-time coating method, use 130 wire mesh roller to coat the transfer coating on the PET film, center the edge when coating, control the width of the edge on one side to be 0.5mm, dry coat The amount is 1.65g / m 2 ;

[0038] (3) Molding: temperature 165°C, pressure 0.32Mpa, speed 55m / min, press laser pattern, the pattern is clear and translucent;

[0039] (4) Aluminum plating: vacuum aluminum plating is carried out on the transfer layer on a vacuum aluminum plating machine under a vacuum degree of 0.3Pa and a temperature of 160°C. The thickness of the aluminum plating layer is aluminum coating;

[0040] (5) Composite: 8.5g / m 2 ...

Embodiment 3

[0044] The preparation method of the anti-counterfeiting transfer paper with small crystal point effect comprises the following steps:

[0045] (1) Preparation of transfer coating: use modified acrylate polymer as base resin and add 0.2% anti-counterfeiting material to prepare transfer coating;

[0046] (2) Coating: One-time coating on one side is adopted, and the transfer coating is coated on the PET film using a 130-line screen roller, and the card edge is centered during coating, and the width of the card edge on one side is controlled to be 0.4 mm. The amount is 1.65g / m 2 , and then laminated to obtain a pearlescent transfer layer;

[0047] (3) Molding: the temperature is 165°C, the pressure is 0.32Mpa, the speed is 55m / min, and the laser pattern is pressed. The pattern is clear and transparent;

[0048] (4) Aluminum plating: vacuum aluminum plating is carried out on the transfer layer on a vacuum aluminum plating machine under a vacuum degree of 0.3Pa and a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com