Expansion liner hanger

A liner hanger and expansion pipe technology, which is used in wellbore/well components, earth-moving drilling, etc., can solve the problems of poor cementing quality in the overlapping section of the liner and the limitation of wellbore size, so as to improve safety, reliability, The effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0015] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is described according to the layout of the drawings in the specification, such as: the positional relationship of front, rear, upper, lower, left, right, etc. is It is determined according to the layout direction of the attached drawings.

[0016] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

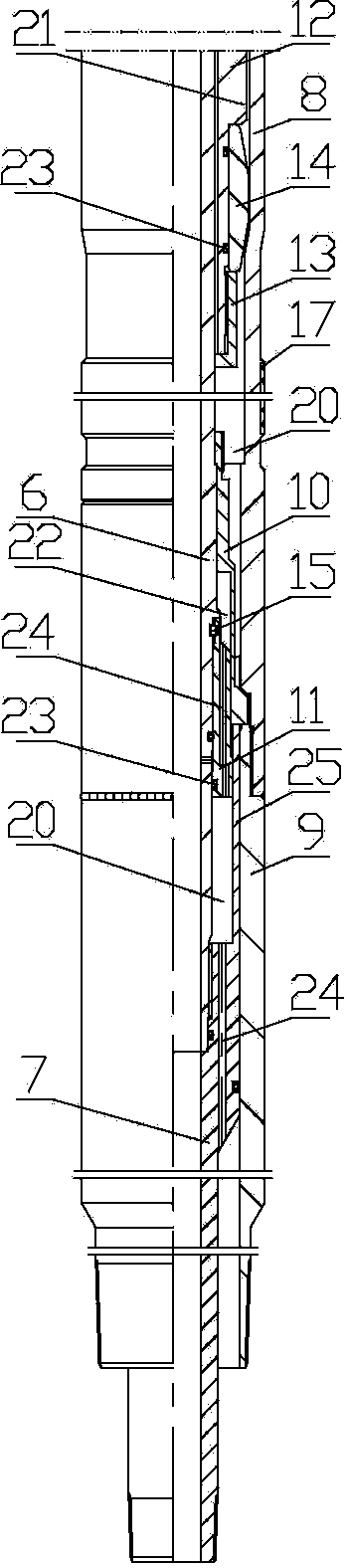

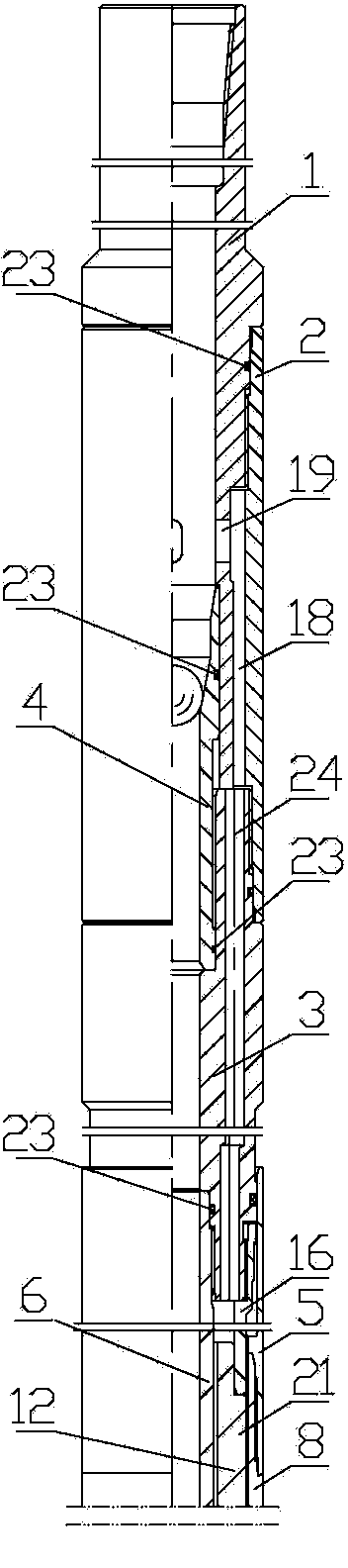

[0017] as attached figure 1 , 2 As shown, the expansion liner hanger includes an upper joint 1, a connecting sleeve 2, a bypass valve 3, a ball seat 4, a tie-back sleeve 5, a center pipe 6, a return piece 7, an expansion pipe 8 and a lower joint 9; the upper joint The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com