Waterwheel rotor of concave-convex baffle plate

A technology of damper and water wheel, which is applied in hydroelectric power generation, machines/engines, mechanical equipment, etc. It can solve problems such as difficult to improve the working efficiency of water wheels, energy single-machine conversion, and affecting energy conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

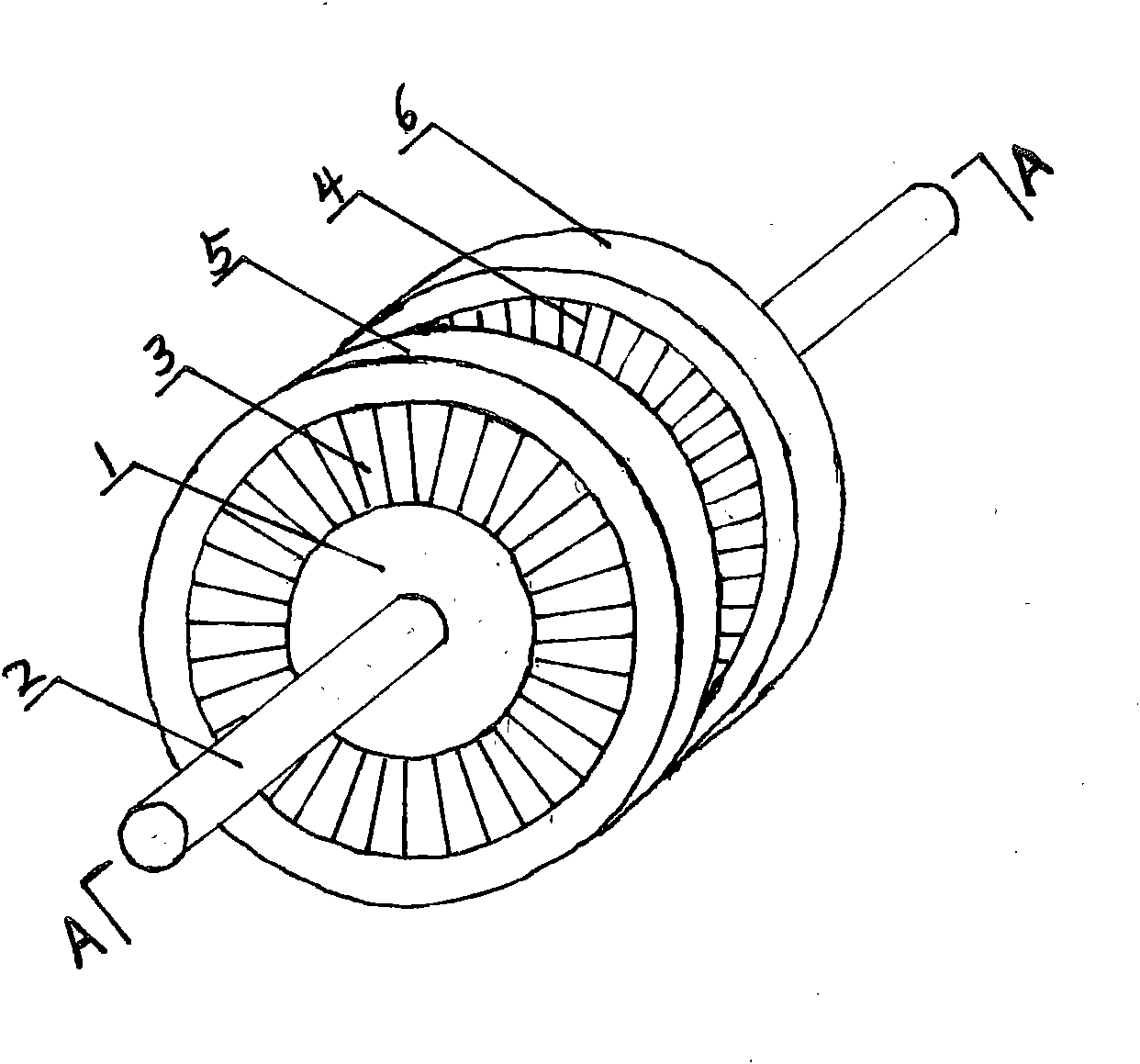

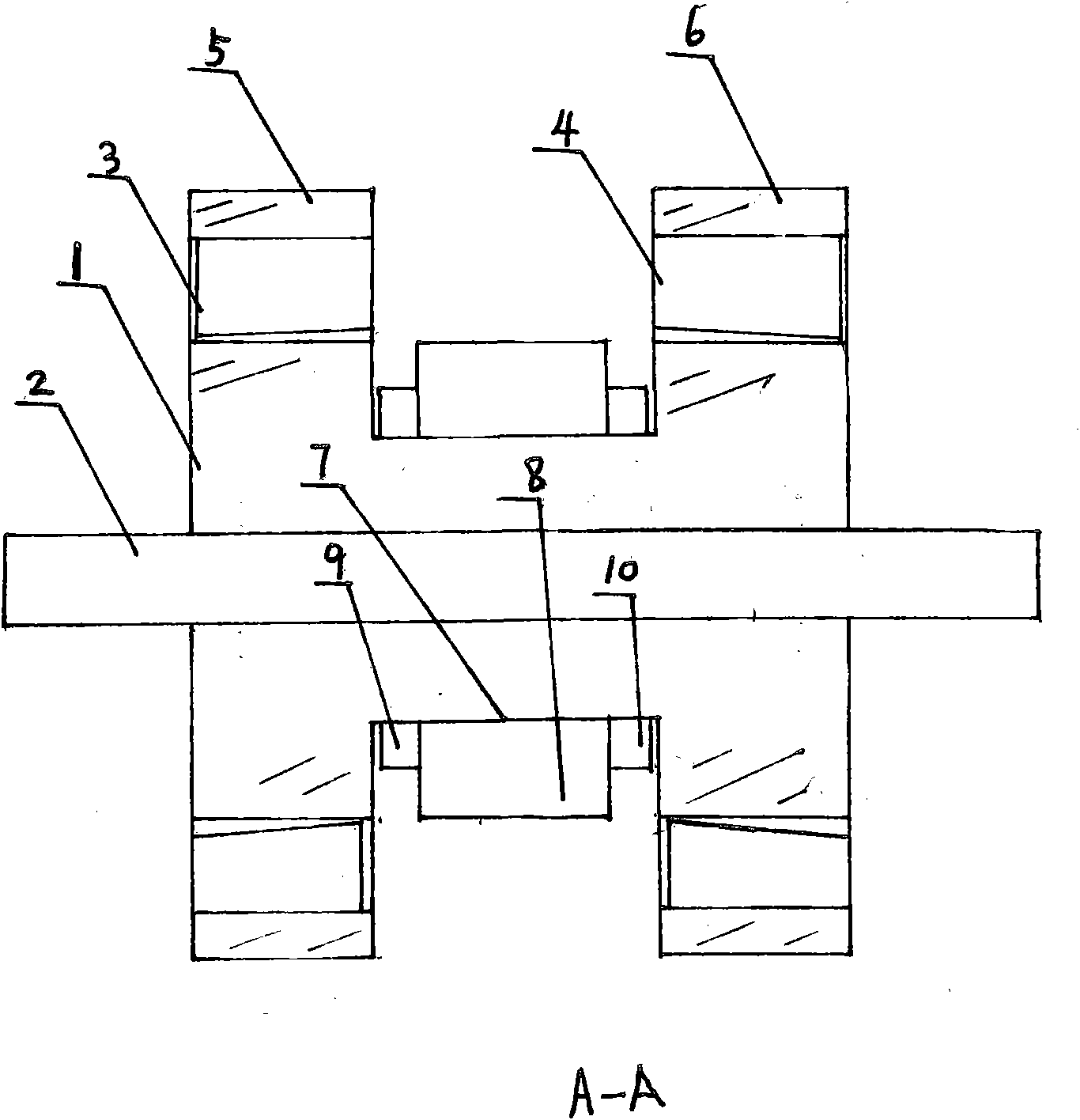

[0007] A water wheel rotor with concave-convex baffles, including a shaft body 2 protruding from both sides of a swivel 1, a swivel 1 supported by flow control plates 3, 4, and flow control baffles 3, 4 supported by ferrules 5, 6 , because both sides phase type, the middle is groove 7, is provided with resistance plate 8 in groove 7, and resistance plate 8 both sides is provided with discharge afterburner plate 9,10.

[0008] Utilize the hydraulic turbine of the water wheel rotor of concave-convex baffle plate, the water flow pressure is provided with discharge force plate 9,10 on both sides of resistance plate 8 and is stressed at the same time, and the water wheel rotor rotates, and the both sides of swivel 1 are supported and provided with flow control baffle plate 34 and simultaneously Force is added, and force is transmitted at the same time. Driven by the force, the rotor runs at a high speed. However, on a water flow pressure pipe, the hydraulic turbine of the water whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com