Wiring structure of touch panel and manufacturing method thereof

A wiring structure and touch panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of high equipment power, high operating cost, and large resource consumption, and achieve equipment power low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

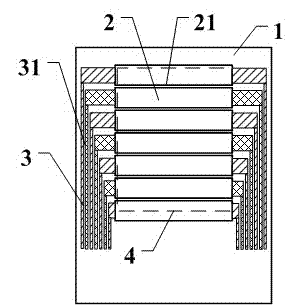

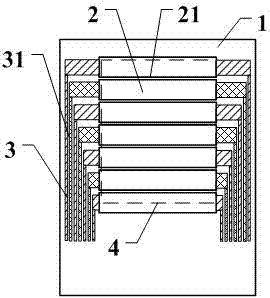

[0026] like figure 1 As shown, it is a schematic diagram of a specific touch panel wiring structure. It can be seen from the figure that the touch panel includes a substrate 1 and a transparent conductive film 2 coated thereon, wherein the transparent conductive film covers at least the entire substrate. The functional area 4, and the transfer line 3 is arranged on the substrate through the functional area. In order to realize the touch function, the transparent conductive film 2 is provided with a plurality of dividing lines 21 in the functional area corresponding to each line of the transfer line low-resistance conductive film, wherein the minimum line width of the dividing line is 10 μm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com