Reactor core design method for improving reactivity and transmutation effect of homogeneous spent fuel solution transmutation reactor

A design method and spent fuel technology, applied in the direction of reactors, manufacturing reactors, climate sustainability, etc., can solve the problem of not describing the core design method of spent fuel solution transmutation, and achieve the effect of improving the reactivity of the core

Active Publication Date: 2012-03-14

NUCLEAR POWER INSTITUTE OF CHINA

View PDF5 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the Chinese patent application number 200810045716.8 "Solution reactor for plutonium incineration and neptunium-237 or americium-241 transmutation" describes such a spent fuel solution transmutation reactor, but does not describe the core of the spent fuel solution transmutation reactor design method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

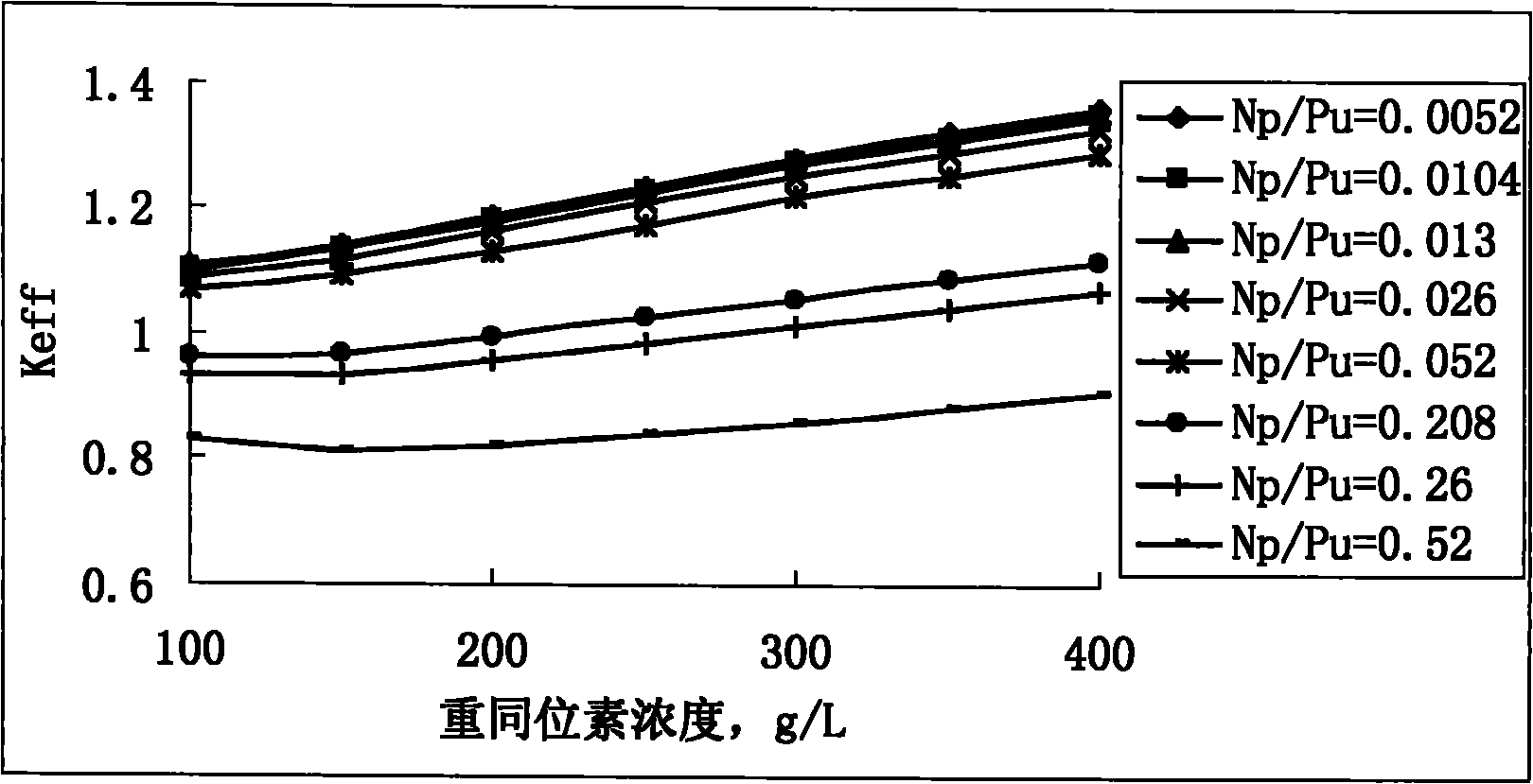

[0066] Heavy isotopes in fuel solutions contain only 237 Np and plutonium, 237 The Np / Pu ratio was 0.26.

Embodiment 2

[0068] Heavy isotopes in fuel solutions contain only 237 Np and plutonium, 237 The Np / Pu ratio was 0.052.

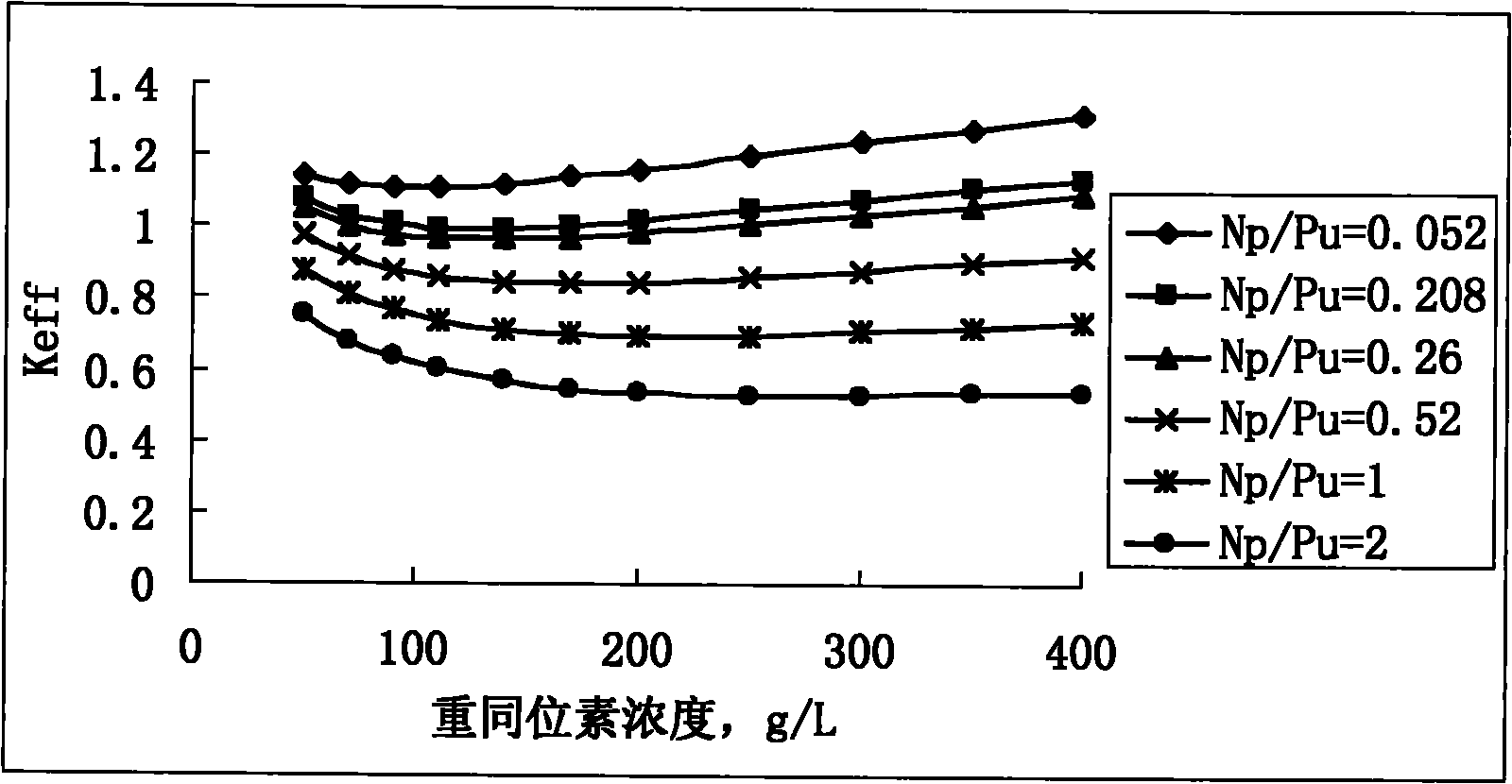

Embodiment 3

[0070] into the fuel solution 237 Np and 241 The content of Am increased to 5 times that of Example 2, and the content of other nuclides remained unchanged.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

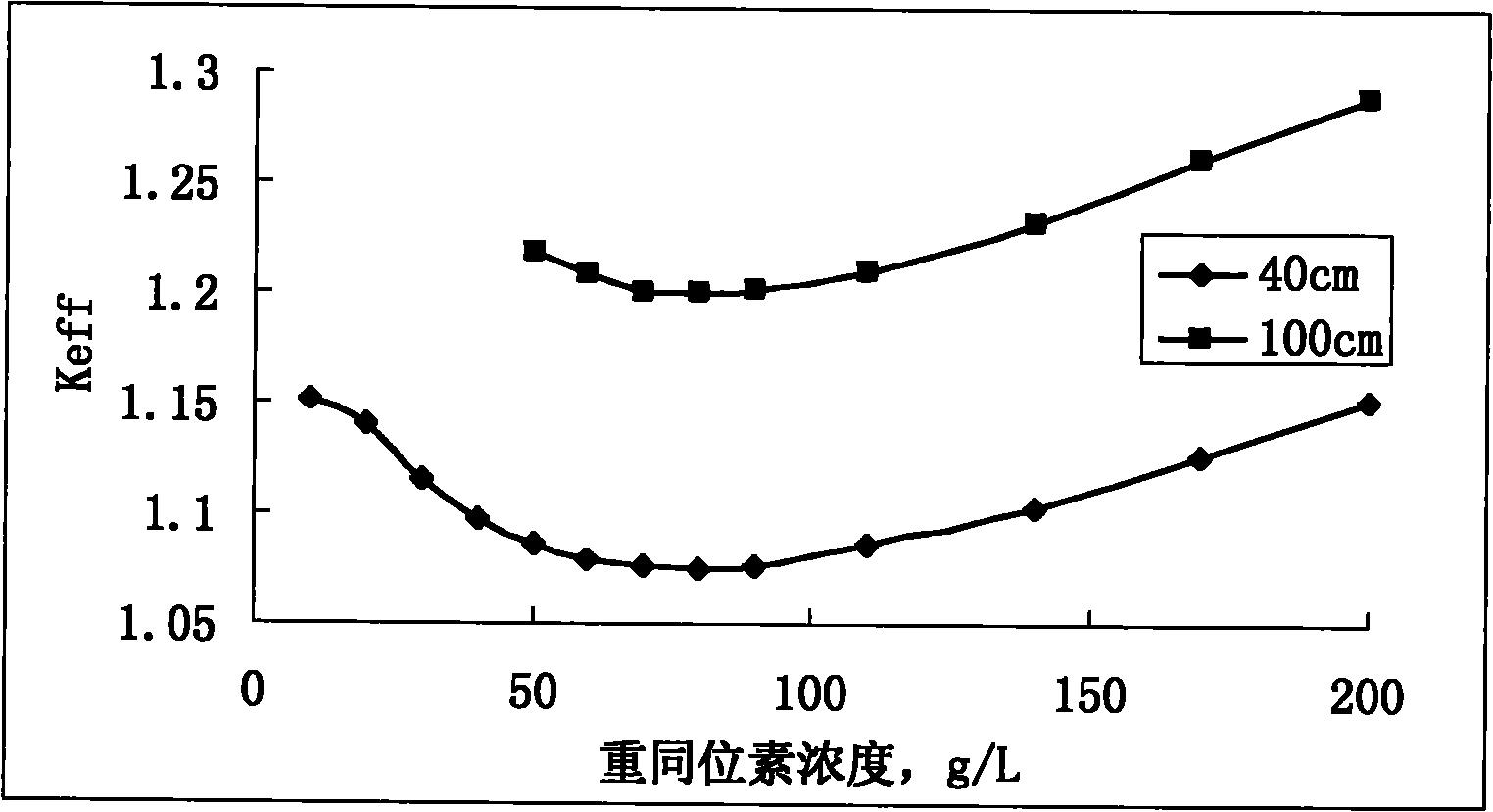

The invention discloses a reactor core design method for improving the reactivity and the transmutation effect of a homogeneous spent fuel solution transmutation reactor, which comprises the following steps: according to the component proportion of a plutonium isotope to a minor actinide in spent fuel, preparing reactor core spent fuel solution; determining the radius dimension of a reactor core, the arrangement material and the thickness of a reflecting layer, the heavy isotope concentration and the heavy isotope nuclide proportion; and calculating the critical performances of the reactor core under various reactor core parameters, wherein 100cm is selected to serve as the radius dimension of the reactor core; the height of the solution is 200cm, and light water of which the thickness is 10cm is adopted in the radial direction of the reactor core is used as the reflecting layer; 200g / L is selected to serve as the heavy isotope concentration; the ratio of 237Np / Pu is 0.26-0.52; and the light water is selected to serve as a moderator of the reactor core. The method disclosed by the invention can improve the reactivity of the reactor core, and is beneficial to burning more plutonium and obtaining more transmutation products.

Description

technical field [0001] The invention belongs to a core design method of a nuclear reactor, in particular to a core design method of a spent fuel solution transmutation reactor. Background technique [0002] The reprocessing of spent fuel is a key issue that puzzles the development of nuclear power in the world. At present, there are two ways of reprocessing spent fuel: one is the "one-pass" cycle; the other is the "reprocessing" cycle. The "one-pass" method means that the spent fuel is sent to deep geological formations for disposal or long-term storage as waste after cooling and packaging. Its advantages are low cost, simple concept, no high-purity plutonium, and low risk of nuclear proliferation, but the disadvantage is that waste The radioactivity and toxicity are high, and the duration lasts for hundreds of years, and there is no industrial operation experience. The "reprocessing" cycle is to separate and recycle 96% of the useful nuclear fuel contained in the spent fu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G21C21/02

CPCY02E30/30

Inventor 王连杰吴英华汪量子李庆于颖锐

Owner NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com