Evaluation method for corrosion test of automobile radiator

A technology of automobile radiator and corrosion test, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, scientific instruments, etc., can solve the problems of radiator corrosion failure, etc., to achieve good reproducibility, controllable test process, and short test period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

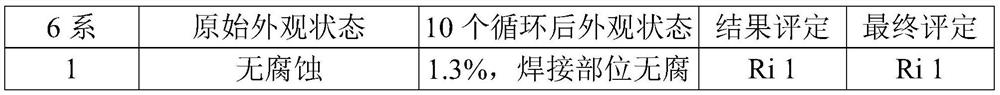

[0058] Embodiment 1 checks the corrosion resistance of 6 series aluminum alloy radiator

[0059] (1) Test method

[0060] Alternating climate test → damp heat test → alternating corrosion test

[0061] The climate change test adopts the FAW standard Q / CAM-64.8 climate change test method, which includes the following steps: The test sample is stored in a climate change test box with a test temperature of 80°C±2°C for 15.5h, and then stored in GB / T Store under 9278 conditions for 0.5h for state adjustment. The same sample is stored in a climate change test chamber at -40°C±2°C for 7.5h, and then stored under the conditions of GB / T 9278 for 0.5h for state adjustment. This is a cycle of climate change test.

[0062] The alternating corrosion test adopts the FAW standard Q / CAM-62.2 cyclic corrosion alternating test method, which includes the following steps: conduct a 4h salt spray test according to the test method in ISO 9227 Corrosion test in artificial environment-salt spray t...

Embodiment 2

[0076] Embodiment 2 checks the corrosion resistance of 3 series aluminum alloy radiators

[0077] (1) Test method

[0078] Alternating climate test → damp heat test → alternating corrosion test

[0079] (2) 10 cycle tests

[0080] One cycle is: high temperature (80℃±2℃, 80%RH)×15.5h→(room temperature)×0.5h→low temperature (-40℃±2℃)×7.5h→(room temperature)×0.5h→→humid heat Test (low humidity 35℃±3℃, 100%RH)×120h→salt spray test×4h→(room temperature)×4h→damp heat test (high humidity 50℃±2℃, 100%RH)×15.5h→(room temperature) ×0.5h, 7 days in total, 70 days in 10 cycles.

[0081] (3) After 10 cycle tests are completed, the airtightness test of the radiator is good (no air leakage at 5 bar pressure)

[0082] Table 7 Appearance inspection results of 3-series aluminum alloy radiators

[0083]

[0084] Table 8 Weight loss test results of heat sinks and condenser tubes of 3-series aluminum alloy radiators

[0085]

[0086] Table 9 Test results of sealing performance of 3-ser...

Embodiment 3

[0091] Embodiment 3 checks the corrosion resistance of 4 series aluminum alloy radiators

[0092] (1) Test method

[0093] Alternating climate test → damp heat test → alternating corrosion test

[0094] (2) 10 cycle tests

[0095]One cycle is: high temperature (80℃±2℃, 80%RH)×15.5h→(room temperature)×0.5h→low temperature (-40℃±2℃)×7.5h→(room temperature)×0.5h→→humid heat Test (low humidity 35℃±3℃, 100%RH)×120h→salt spray test×4h→(room temperature)×4h→damp heat test (high humidity 50℃±2℃, 100%RH)×15.5h→(room temperature) ×0.5h, 7 days in total, 70 days in 10 cycles.

[0096] (3) After 10 cycle tests are completed, the airtightness test of the radiator is good (no air leakage at 5 bar pressure)

[0097] Table 11 Appearance inspection results of 4-series aluminum alloy radiators

[0098]

[0099] Table 12 Weight loss test results of radiator fins and condenser tubes of 4-series aluminum alloy radiators

[0100]

[0101] Table 13 Test results of airtightness of 4-serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com