Silicon wafer and production method thereof

A technology of silicon wafers and silicon single crystals, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., can solve problems such as increasing wafer production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

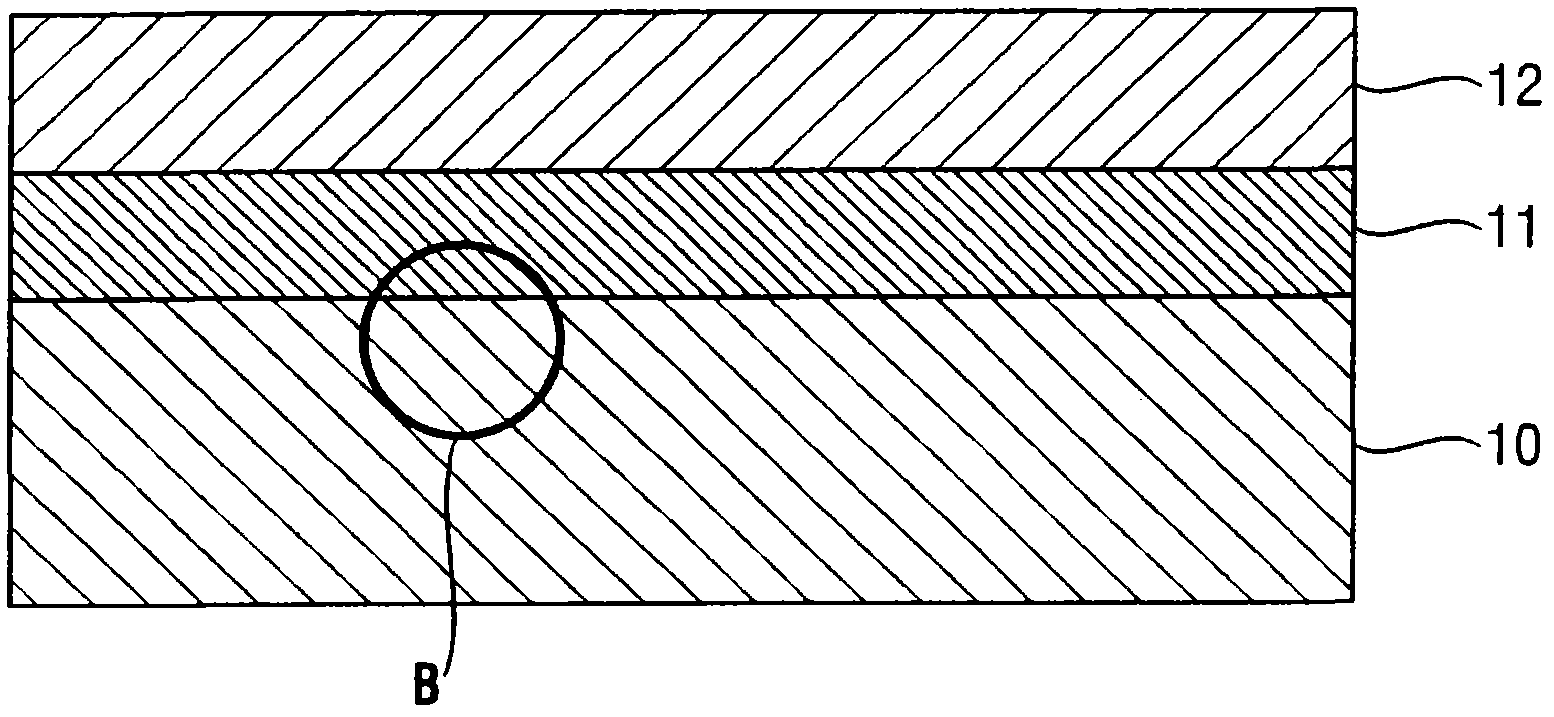

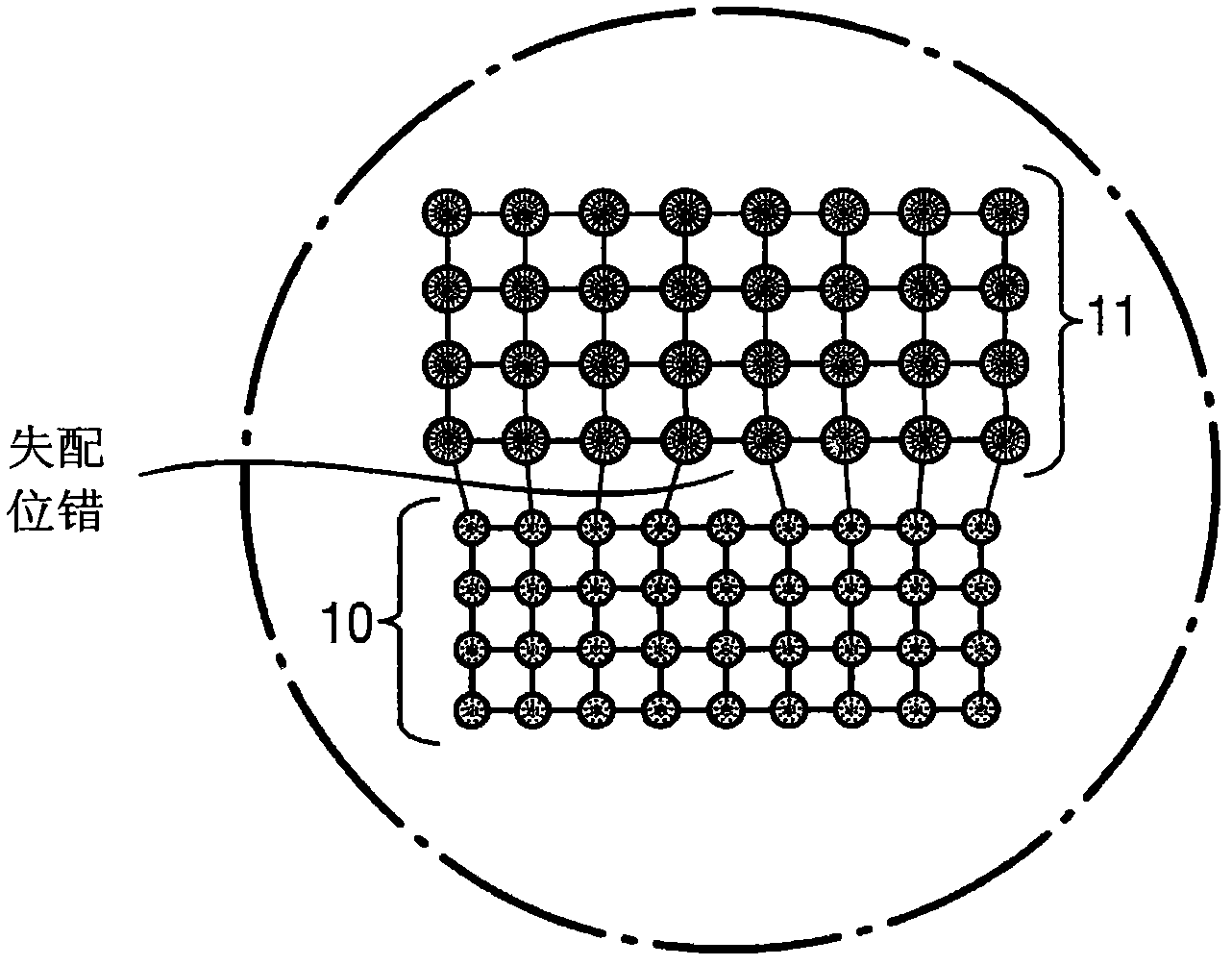

[0170] The mirror wafers were grown by the dicing Czochralski method with a diameter of 200 mm and a phosphorus concentration of 5 × 10 14 atoms / cm 3 n-type silicon single crystal ingots and manufactured by performing a wafer production process on sliced wafers.

[0171] Then, the wafer was set in a separate loading type apparatus for epitaxial vapor phase growth in a lamp heating method, and heat treatment was performed in a hydrogen atmosphere at 1100° C. for cleaning.

[0172] Then, supply SiHCl at 1050°C and standard pressure 3 、GeCl 4 and PH 3 mixed reaction gas. By CVD method, the thickness of 10 μm is grown on the wafer, and the donor concentration (phosphorus concentration) is 7×10 19 atoms / cm 3 And the material (germanium concentration) to adjust the lattice constant is 9×10 19 atoms / cm 3 of the first epitaxial layer.

[0173] The germanium concentration and phosphorus concentration of the first epitaxial layer were measured by SIMS (Secondary Ion Mass Spec...

Embodiment 2

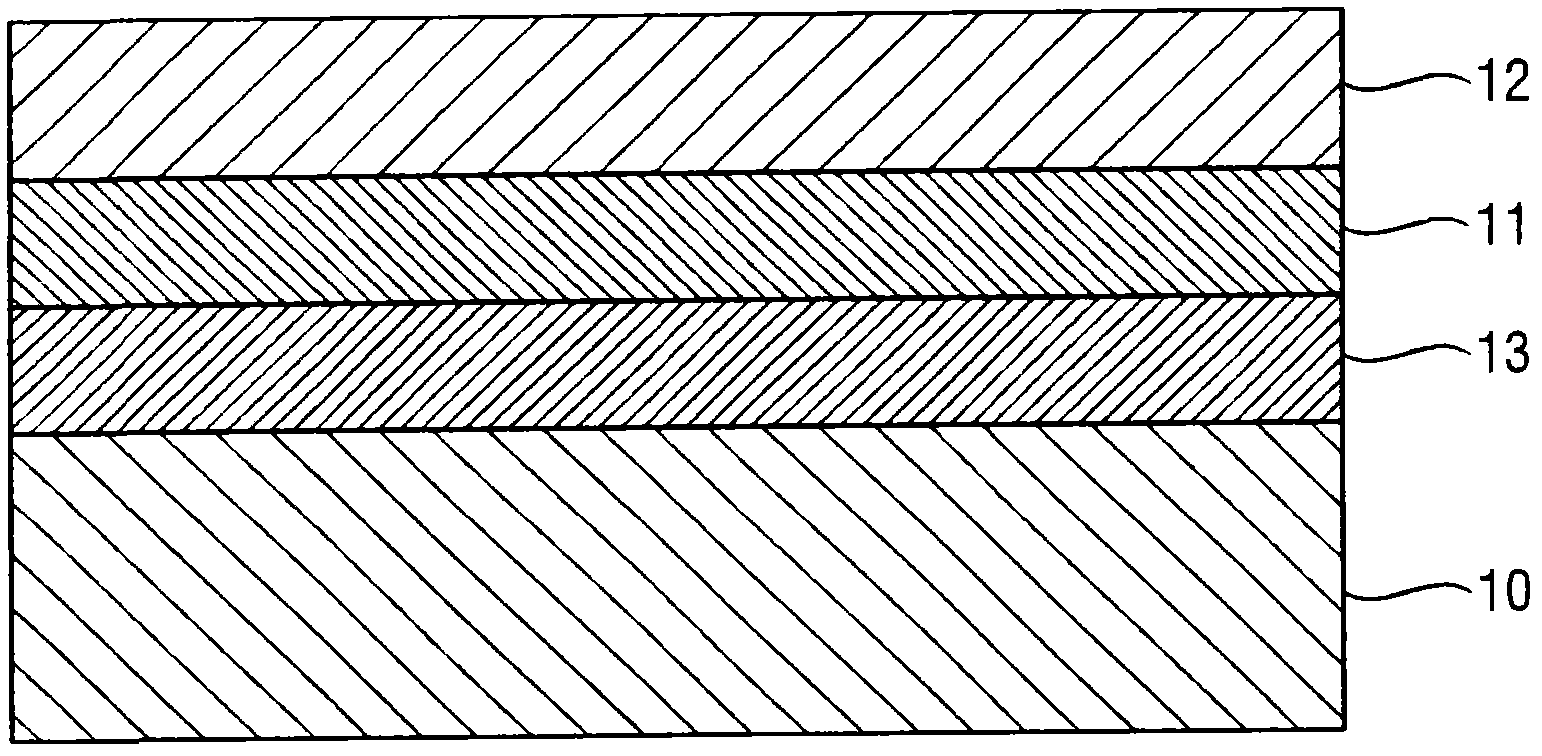

[0179] The mirror wafers were grown by the dicing Czochralski method with a diameter of 200 mm and a phosphorus concentration of 5 × 10 14 atoms / cm 3 n-type silicon single crystal ingots and manufactured by performing a wafer production process on sliced wafers.

[0180] Then, the wafer was set in a separate loading type apparatus for epitaxial vapor phase growth in a lamp heating method, and heat treatment was performed in a hydrogen atmosphere at 1100°C.

[0181] Then, supply SiHCl at 1050°C and standard pressure 3 、GeCl 4 and B 2 h 6 mixed reaction gas. Grown on the wafer by CVD with a thickness of 10 μm and a receptor concentration (boron concentration) of 5×10 19 atoms / cm 3 And the material (germanium concentration) to adjust the lattice constant is 3.3×10 20 atoms / cm 3 The third epitaxial layer (p-type).

[0182] In order to control the concentration of germanium and boron in the third epitaxial layer, B can be changed 2 h 6 gas or GeCl 4 The concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com