Automatic assembling machine of battery cover and assembling method therefor

An automatic assembly machine and battery cover technology, which is applied to battery pack components, circuits, electrical components, etc., to achieve the effects of improved stability, simple structure, and fast feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

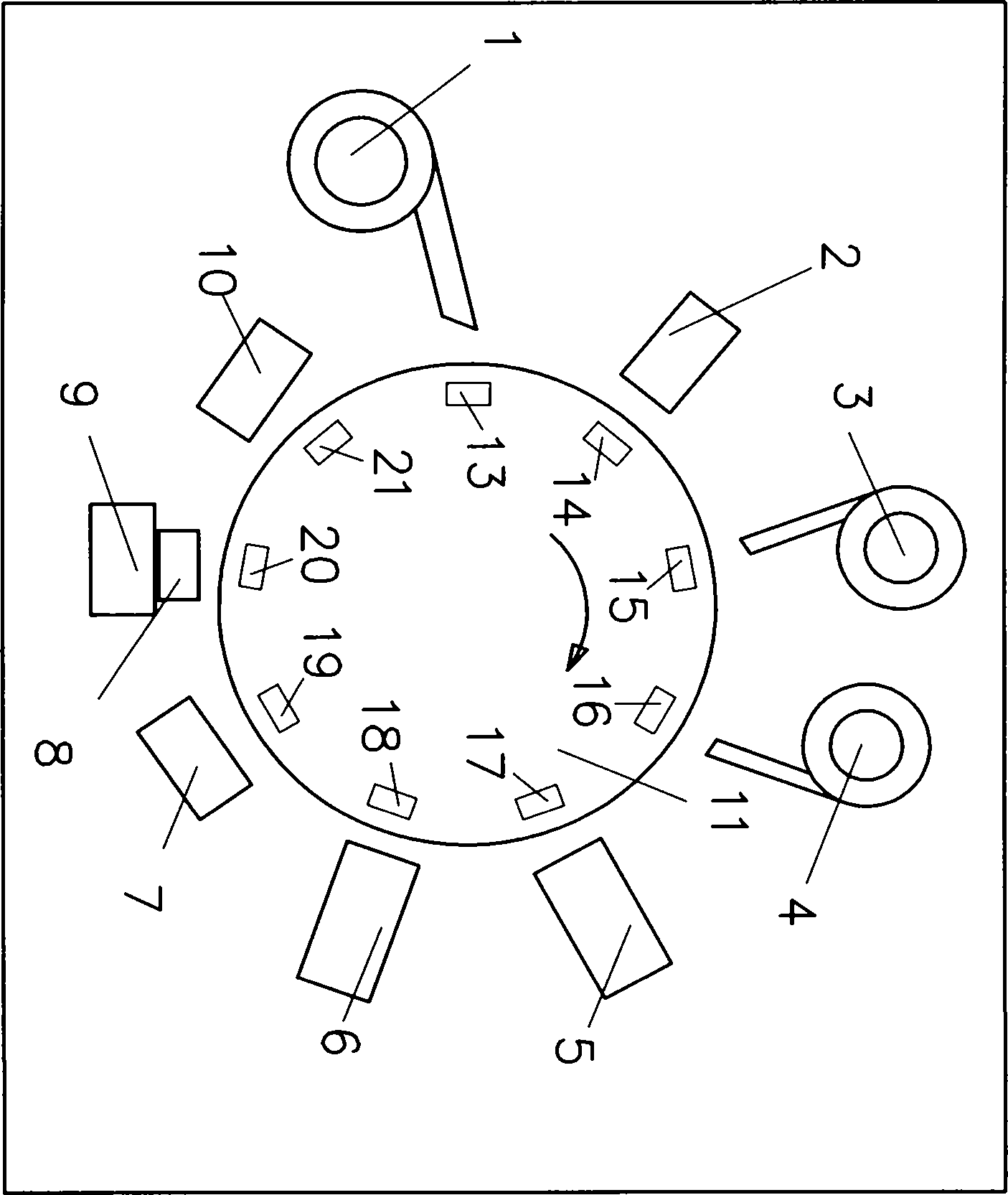

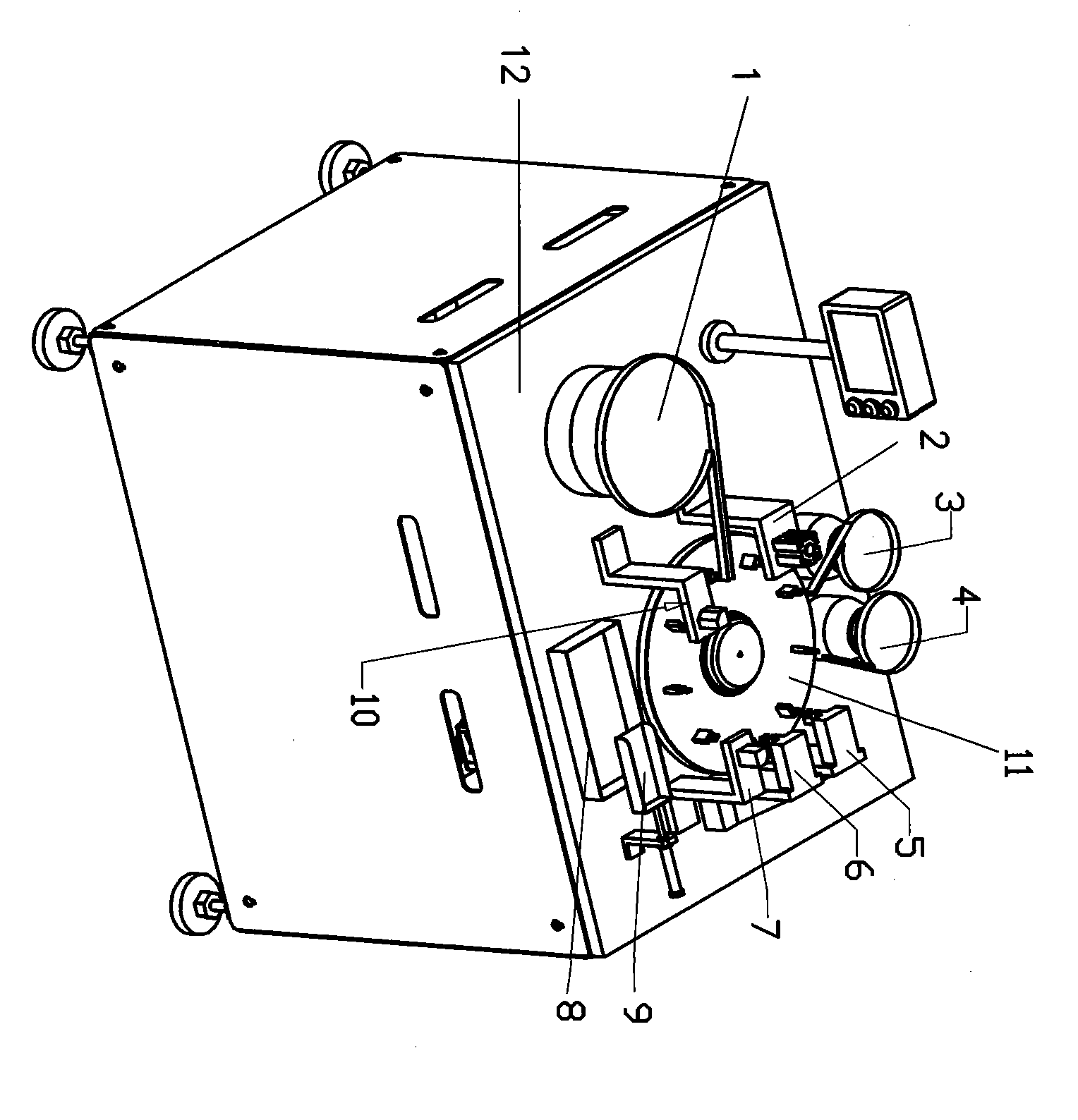

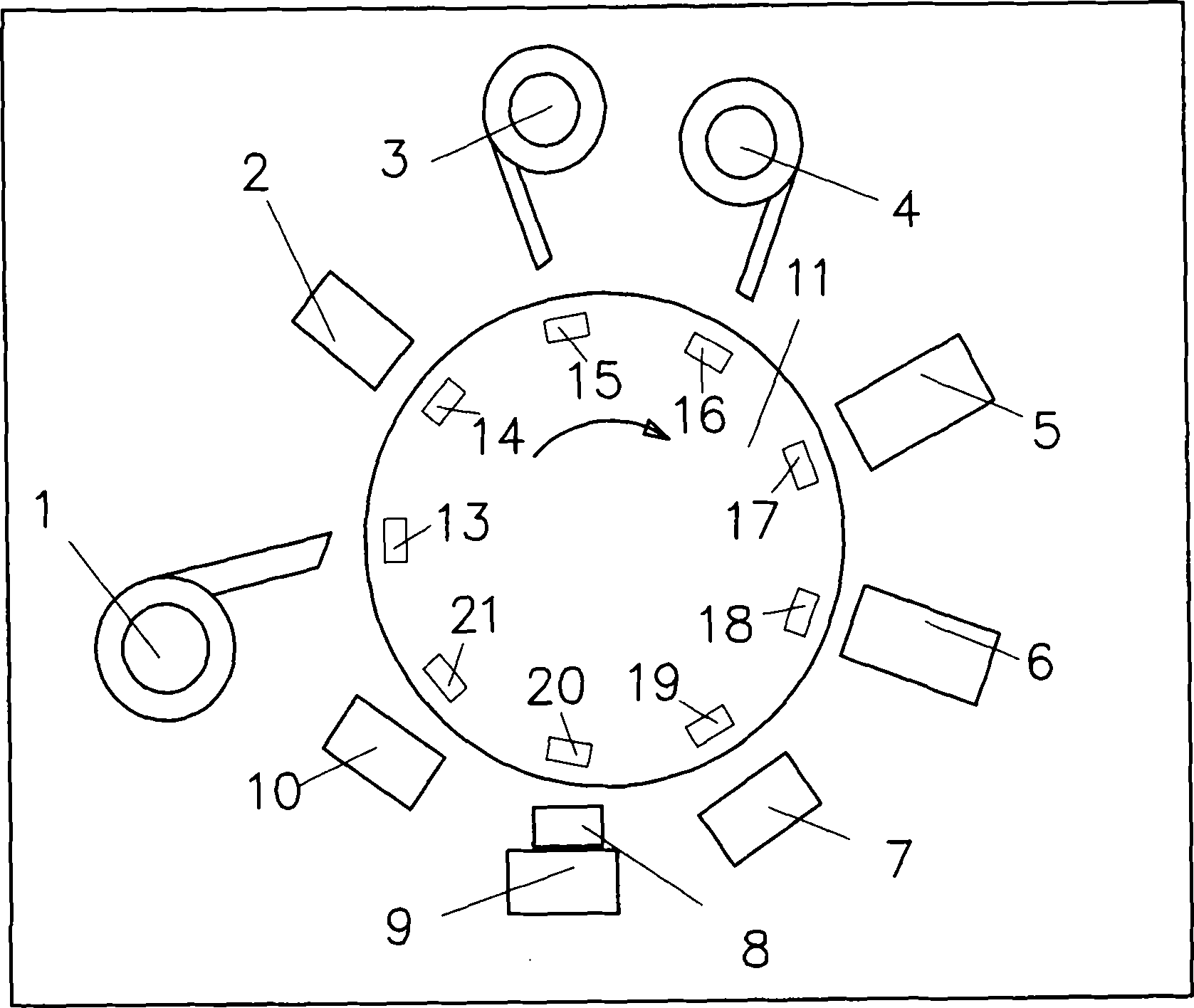

[0025] refer to figure 1 , figure 2 It can be seen that the present invention is an automatic assembly machine for assembling battery covers. A station turntable 11 is provided in the middle of the worktable, and each station on the turntable is provided with a mold for positioning the battery cover and parts. The work around the turntable The position on the table corresponding to the station is provided with a product feeding device 1, a positioning device 2, a primary vibrating plate feeding device 3, a secondary vibrating plate feeding device 4, a primary punching device 5, and a secondary vibrating plate feeding device in a clockwise direction. Stamping device 6 , short circuit detection device 7 , qualified product placement device 8 , unqualified product placement device 9 , and product presence / absence detection device 10 . The product feeding device 1 includes a manipulator feeding device and a vibrating plate feeding device, and the manipulator feeding device is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com