Server machine cabinet and liquid-cooled radiating system thereof

A server cabinet, liquid cooling technology, applied in the field of server cabinets, can solve the problems of difficult heat dissipation, affecting the stability and security of servers, etc., to achieve the effect of improving stability and security, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

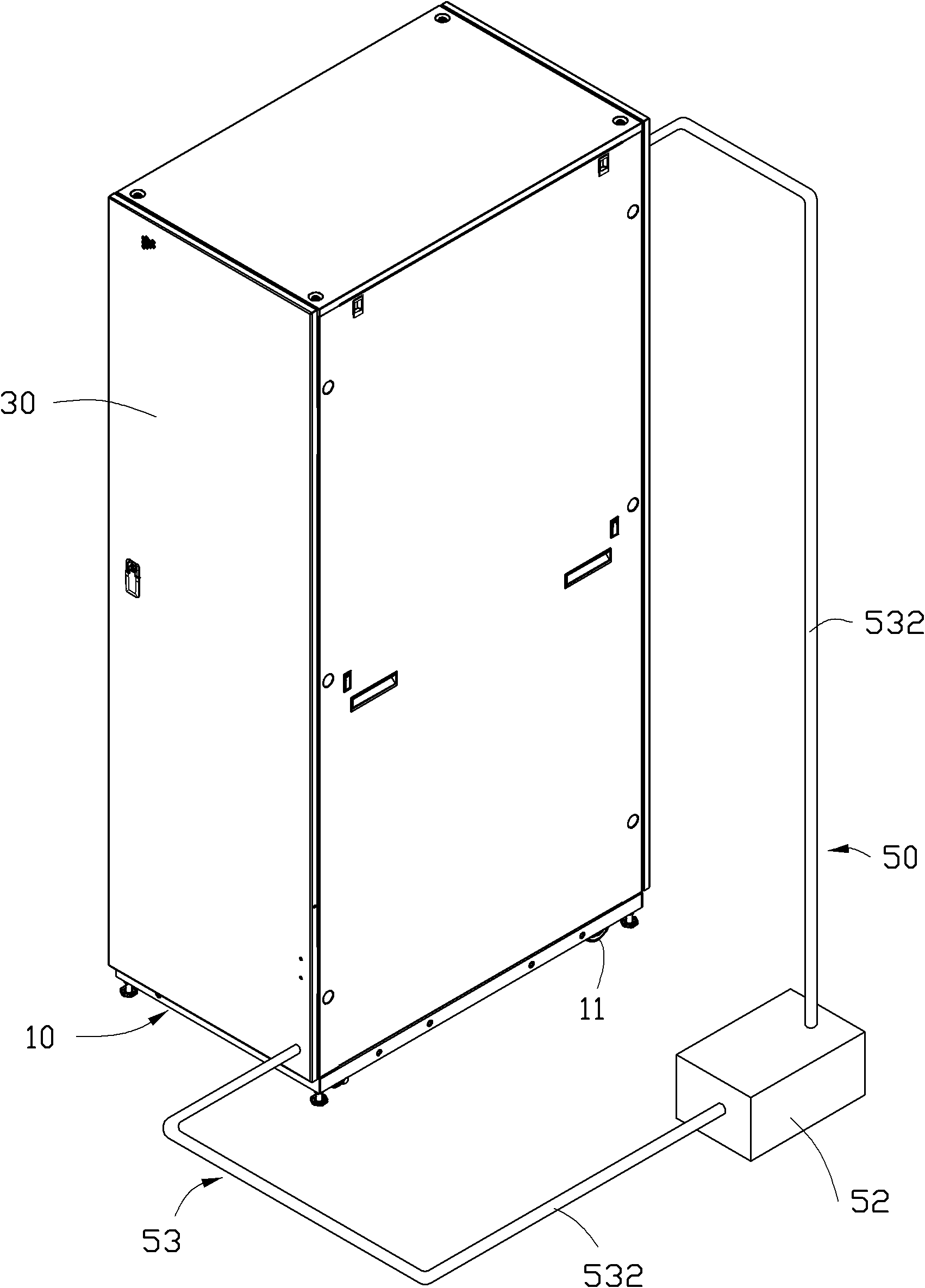

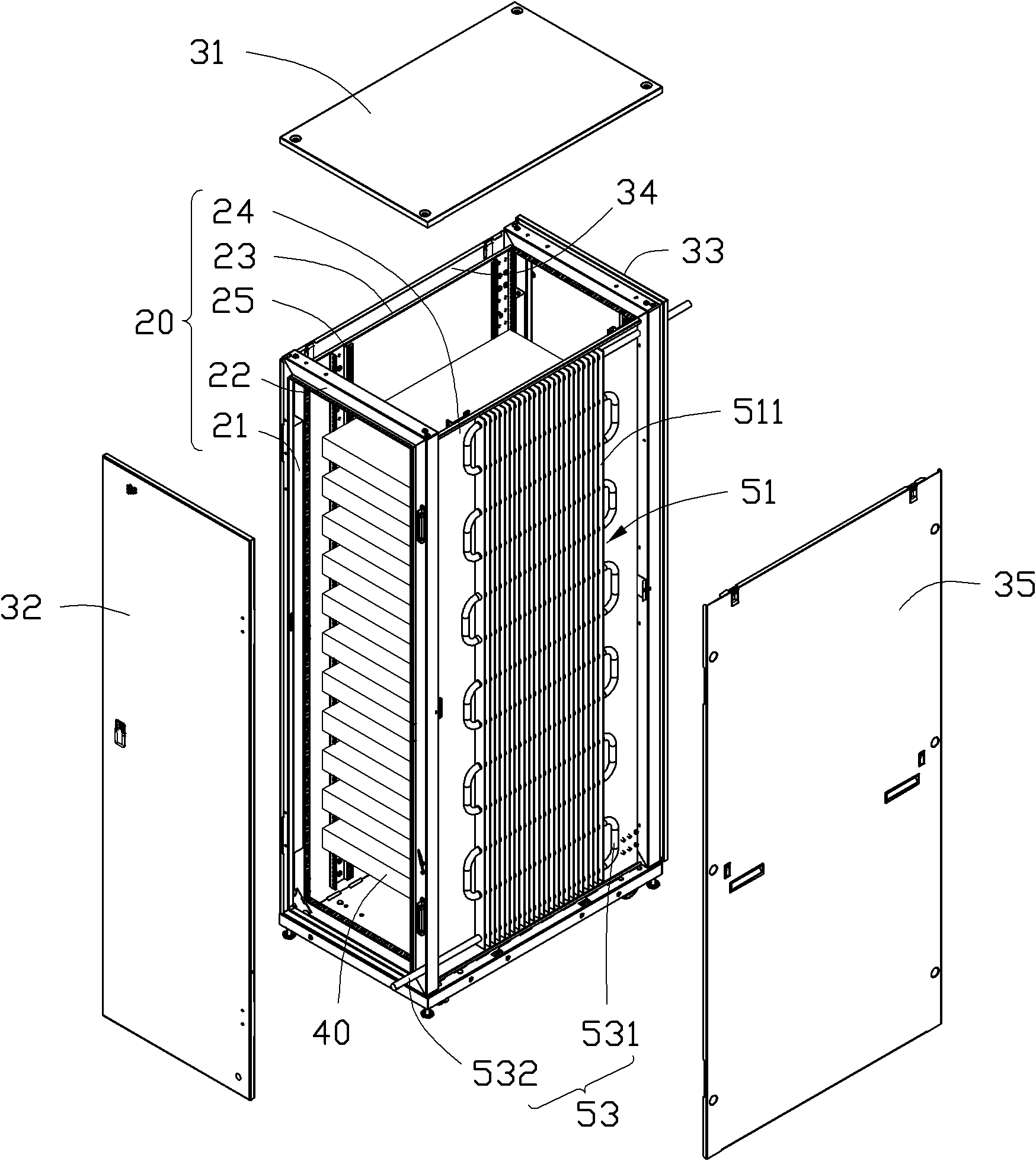

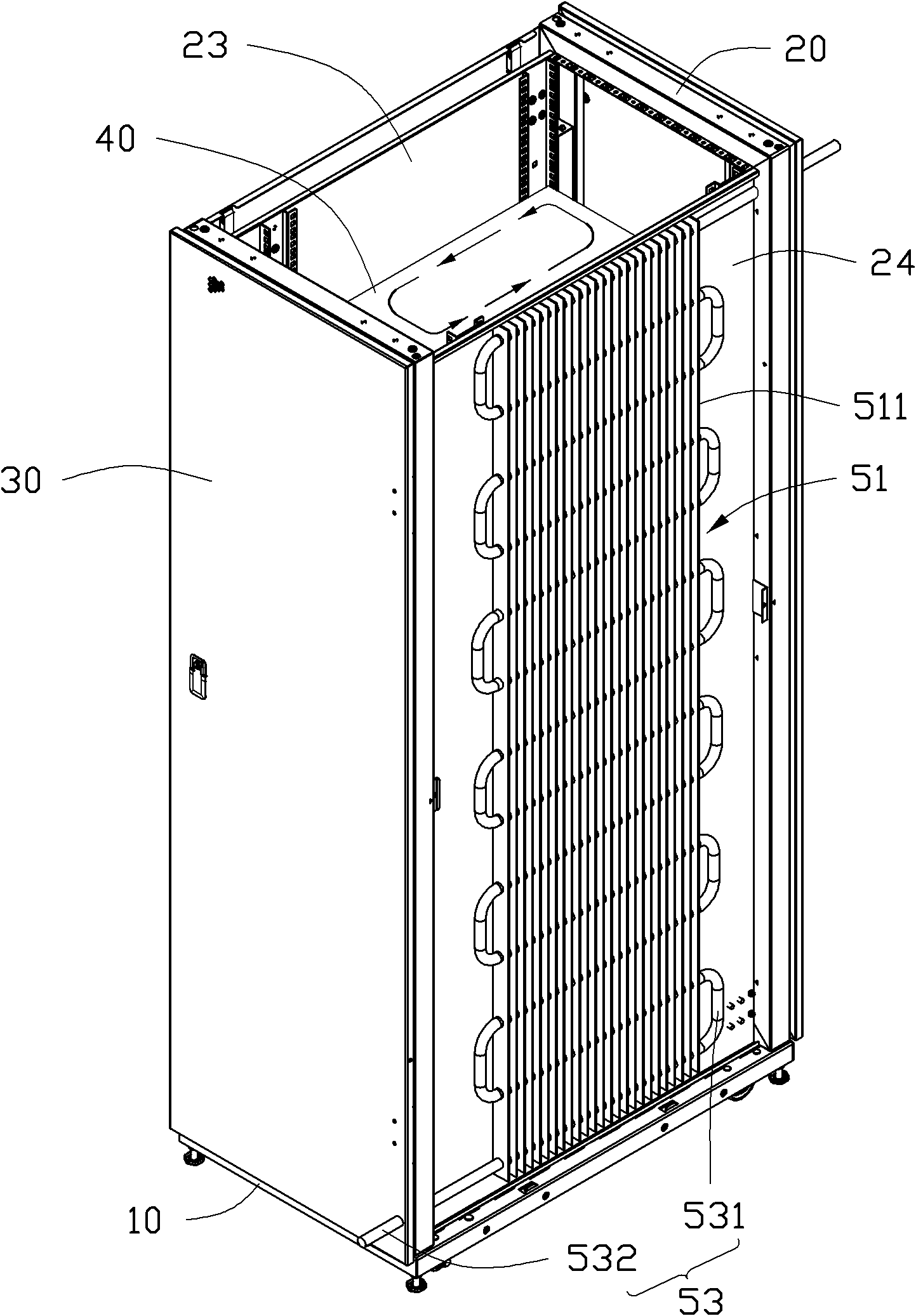

[0032] Figure 1 to Figure 2 Shown is a server cabinet of a preferred embodiment of the present invention, the server cabinet includes a base 10, a frame 20 located on the base 10, a shell 30 located on the periphery of the frame 20, installed on the machine Several servers 40 on the rack 20 and a liquid cooling system 50 for cooling the servers 40 .

[0033] The base 10 is roughly rectangular, and a plurality of rollers 11 are mounted on the bottom thereof to facilitate the movement of the server cabinet.

[0034] The frame 20 is fixed on the base 10 and includes a plurality of columns 21 , a plurality of beams 22 , two heat conducting plates 23 , 24 and two pairs of sliding rails 25 . These columns 21 and beams 22 together form a cube frame shape. The two heat conducting plates 23, 24 are arranged on the left and right sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com