Flexible welding cutting device of workpiece with special section

A special-shaped cross-section and cutting device technology, which is applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of slow groove processing speed, difficult welding, high on-site installation cost, etc., and achieves low cost and compact structure , the effect of exquisite mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

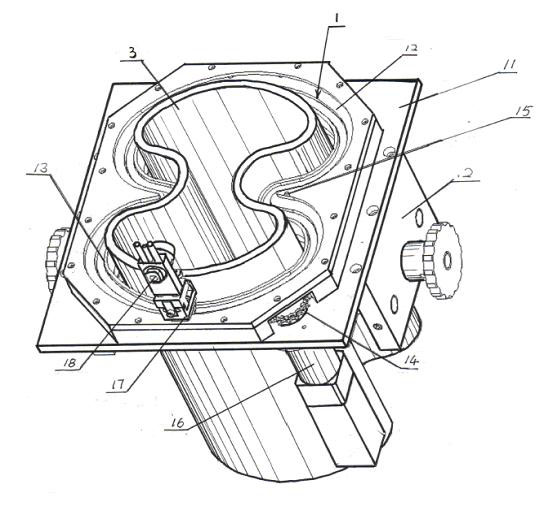

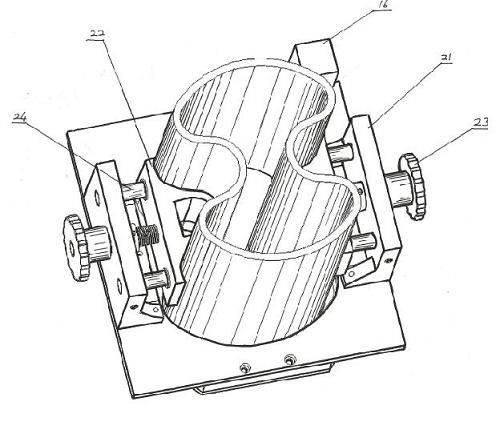

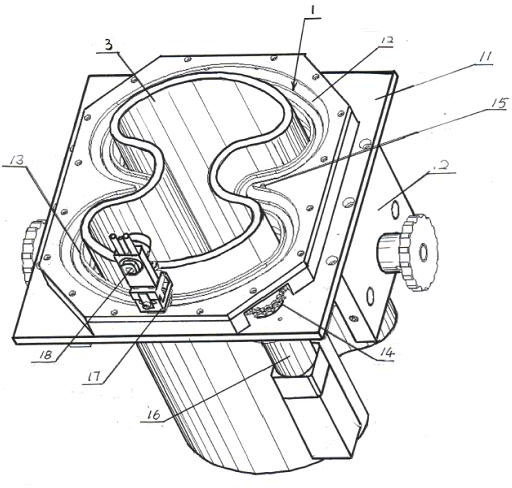

[0024] Depend on figure 1 , figure 2 As shown, a flexible welding and cutting device for special-shaped cross-section workpieces is mainly composed of a flexible transmission device 1 and a workpiece fixing device 2, wherein: the flexible transmission device 1 is composed of a base plate 11, an annular guide rail 12, a transmission chain 13, a transmission sprocket 14, a press wheel 15, transmission motor 16 and welding torch support frame 17; on the base plate 11 is fixed an annular guide rail 12, the transmission chain 13 is embedded in the annular guide rail 12, the transmission motor 16 is arranged below the base plate 11, and drives the transmission sprocket above the base plate 11 14. There are two pressure wheels 15 on the sides of the two depressions in the section of the workpiece 3 to compress the transmission chain 13, which are used to compress the transmission chain 13. The lower end is fixed on the base plate 11, and the bottom of the welding torch support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com