Transport security robot based on omnidirectional moving platform

A motion platform and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as inflexible turning, dead angles in motion, and inability to handle personal safety, achieving the effect of flexible monitoring, flexible handling and disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

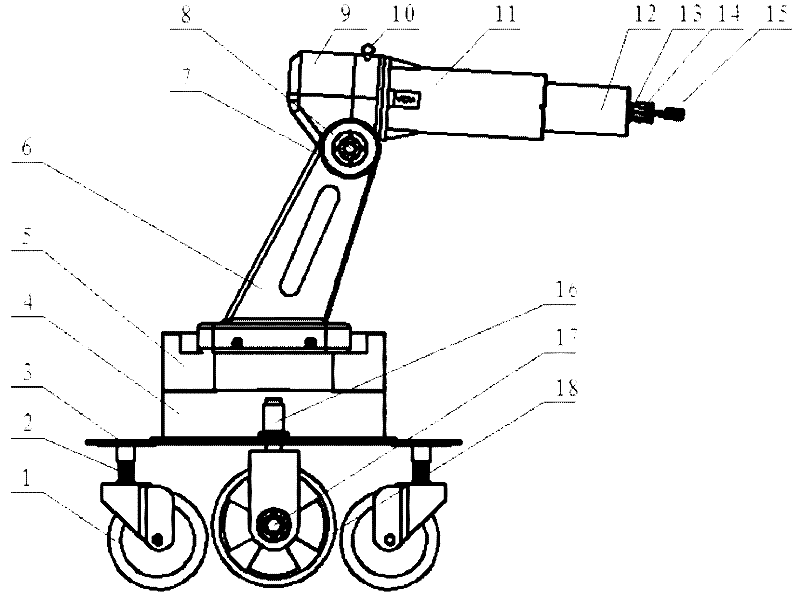

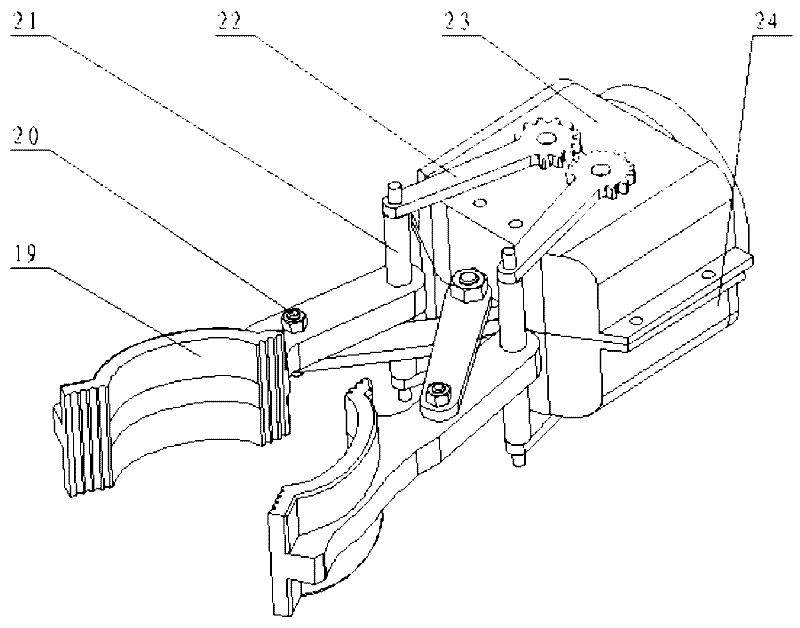

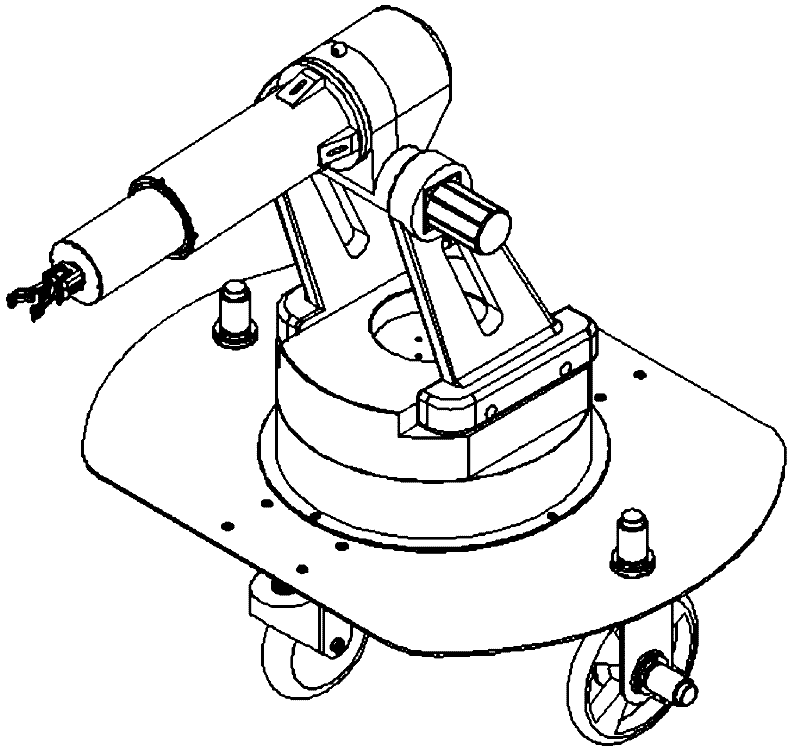

[0017] combine Figure 1~3 , The technical solution adopted in the present invention is: the lower motion platform adopts two driving wheels, two universal wheels serve as driven wheels, and two reduction motors are respectively installed on each driving wheel. One of the geared motors spins the wheels, providing the power needed to move forward. Another reduction motor is fixedly connected on the chassis of the car body, and the input end of the output shaft and the wheel frame body is connected together by keys and pins, thereby realizing the 360° rotation of the frame body. At the same time, the closed-loop control method is used to make the two driving wheels rotate at the same angle, so that there is no dead point in the movement space of the platform. This kind of motion platform can complete the motion of different trajectories without adjusting the postu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com