Reaction fin in front of propeller

A technology of reactive fins and propeller hubs, which is applied in the field of reactive fins in front of propellers, can solve the problems of recovery of wake uniformity and loss of rotational energy in the wake of the propeller, loss of rotational energy in the wake of the propeller, uneven wake field, etc., to achieve The effect of reducing the risk of hull vibration, uniform wake, and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

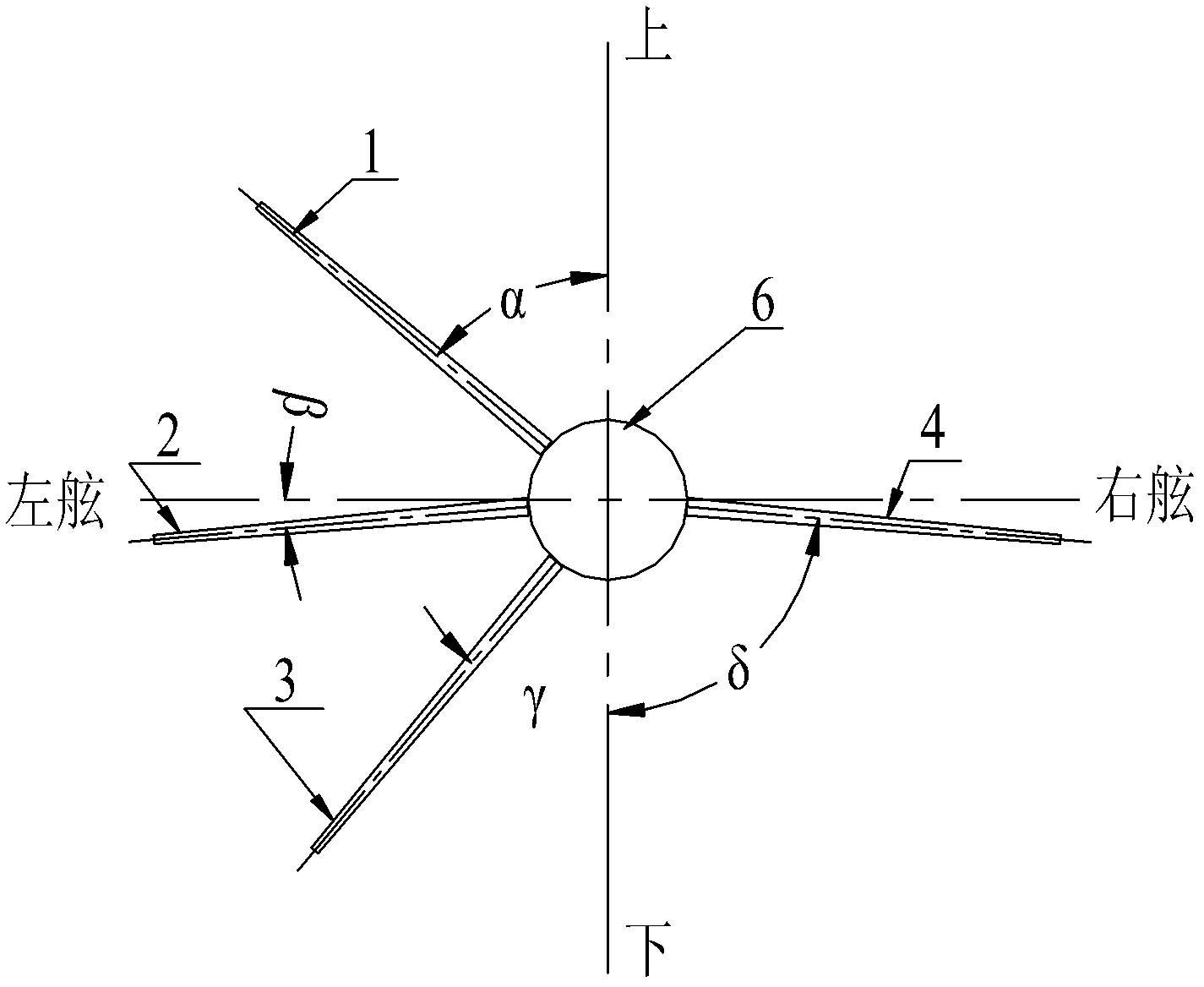

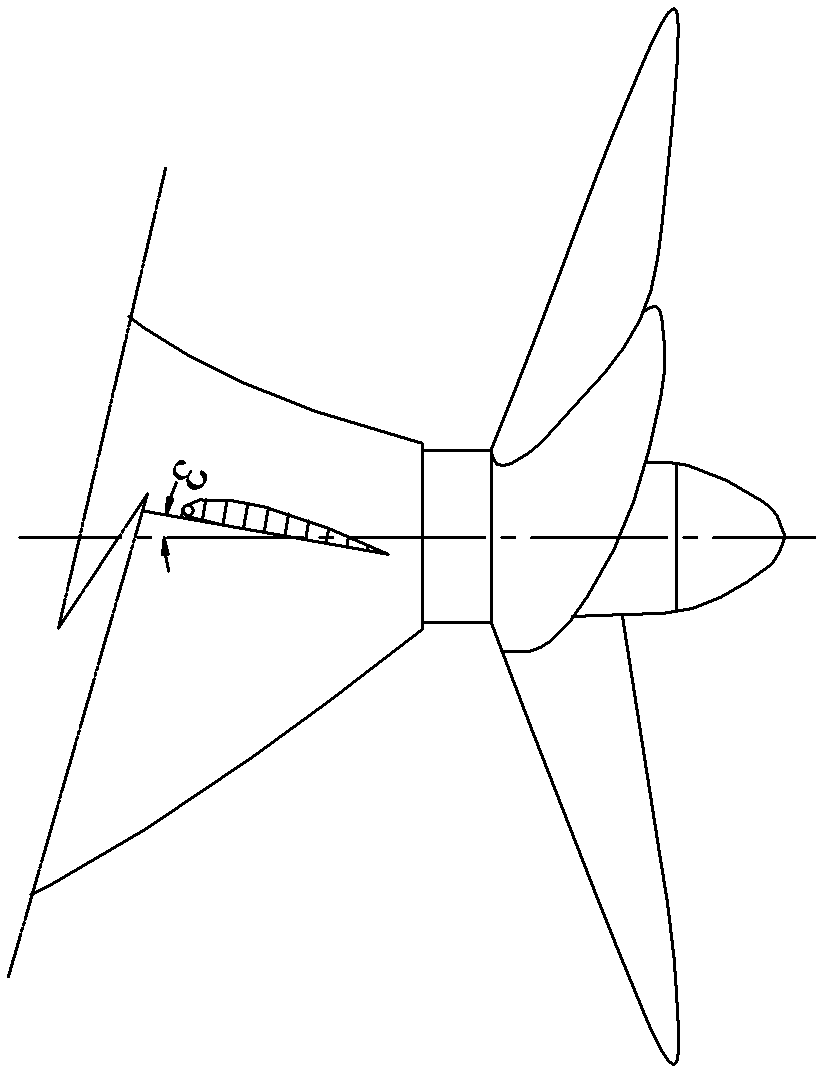

[0018] Such as figure 1 and figure 2 As shown, a kind of paddle front reaction fin, viewed from the rear side of the propeller, is provided with three fins on the stern on the left side of the longitudinal centerline of the propeller hub 6, from top to bottom are the first fin 1, the second fin 2 and The third fin 3 is provided with a fourth fin 4 on the right side, wherein the angle α between the first fin 1 and the longitudinal centerline is in the range of 46°≤α≤53°, and the second fin 2 and the horizontal direction The range of the included angle β is 1°≤β≤8°, the range of the included angle γ between the third fin 3 and the longitudinal centerline is 37°≤γ≤44°, and the range between the fourth fin 4 and the longitudinal centerline The range of the included angle δ is 82°≤δ≤89°.

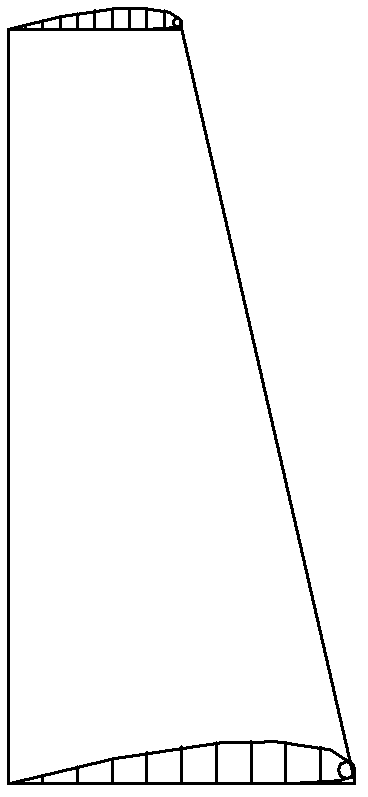

[0019] The shape of the fin is selected from the NACA airfoil with a relatively small drag-lift ratio, but attention should be paid to the overall consideration of the combination of strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com