Disc-taking machine

A technology for taking out the disk machine and the driving pulley, which is applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effect of convenient disassembly, convenient transportation, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

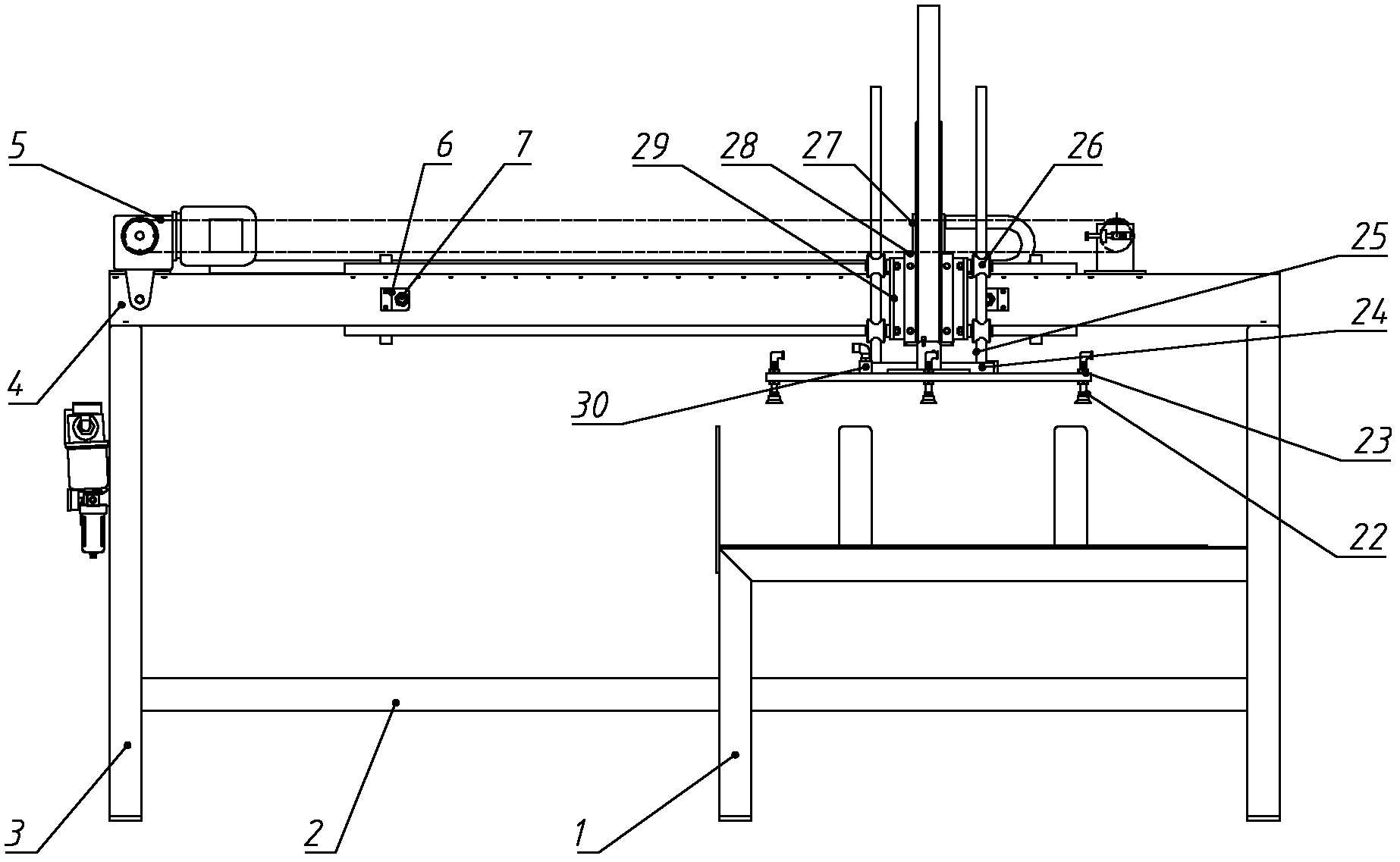

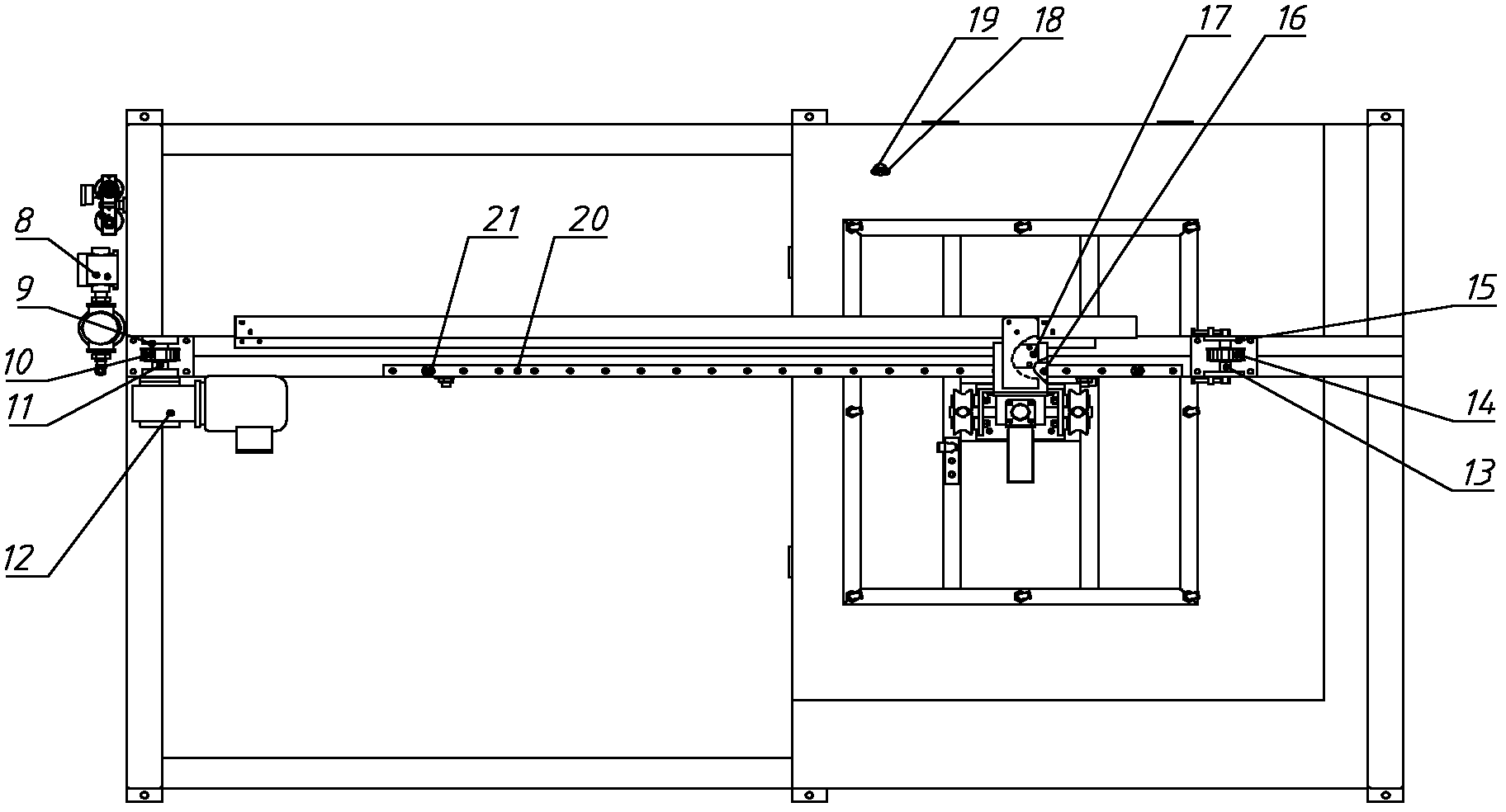

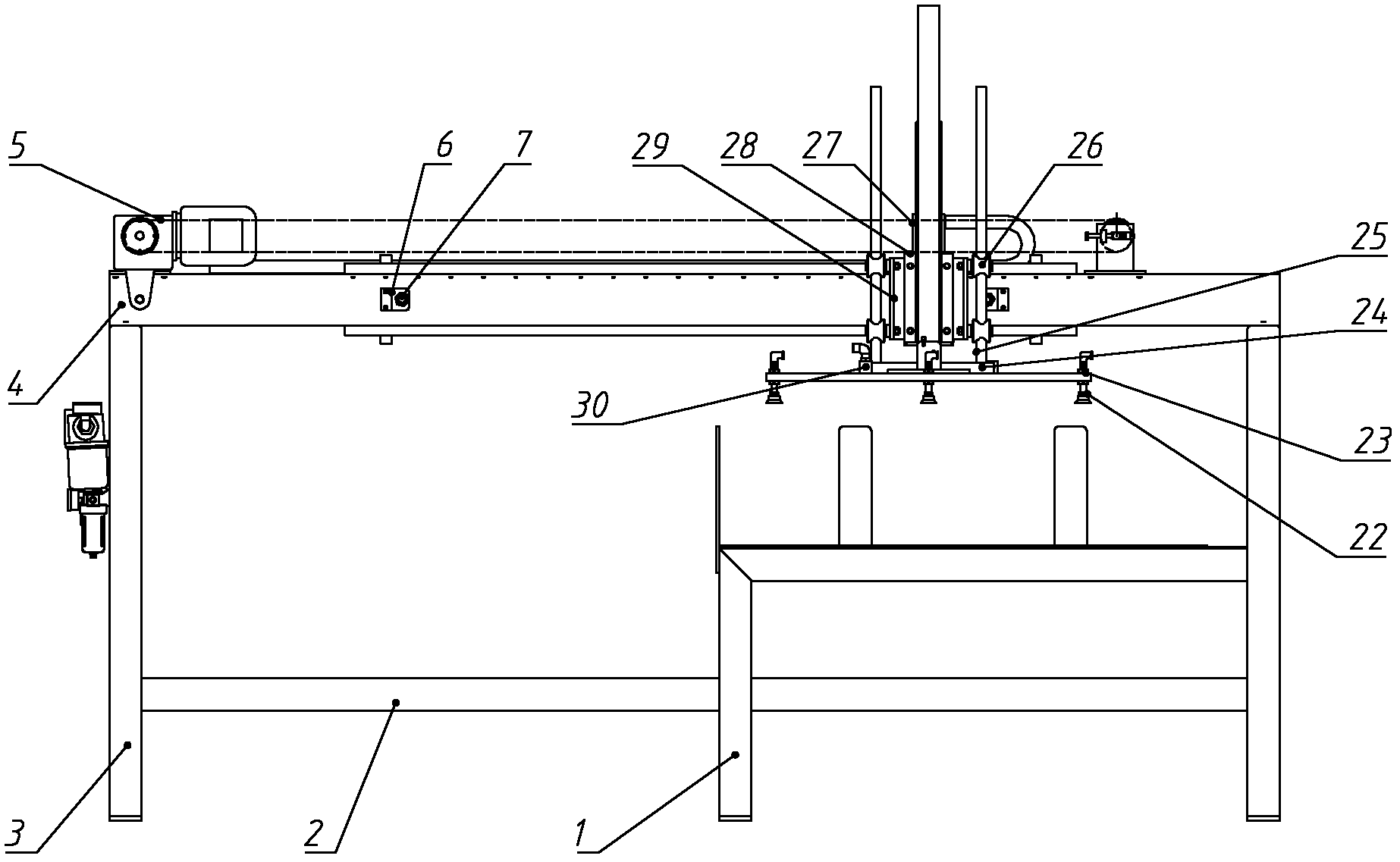

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] Such as figure 1 , 2 As shown, the present invention mainly includes warehouse rack 1, cross brace 2, vertical beam 3, beam 4, synchronous belt 5, 2 pieces of start-stop sensor board 6, 2 pieces of inductive sensor 7, vacuum generator 8, driving pulley seat 9. Driving shaft 10, driving pulley 11, geared motor 12, pulley driven shaft 13, driven pulley 14, driven pulley seat 15, 2 pieces of slider 16, toothed cover 17, sensor bracket at the bottom of the library 18. Diffuse reflection sensor 19, two slide rails 20, four anti-collision blocks 21, suction cup 22, suction cup frame 23, connecting rod plate 24, two guide rods 25, eight rollers 26, bag taking cylinder 27, vertical seat 28. Two pieces of angle steel 29, gas distribution pipe 30, the cross brace 2 connects the storage rack 1 and the vertical beam 3 at the lower end, the cross beam 4 connects the storage rack 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com