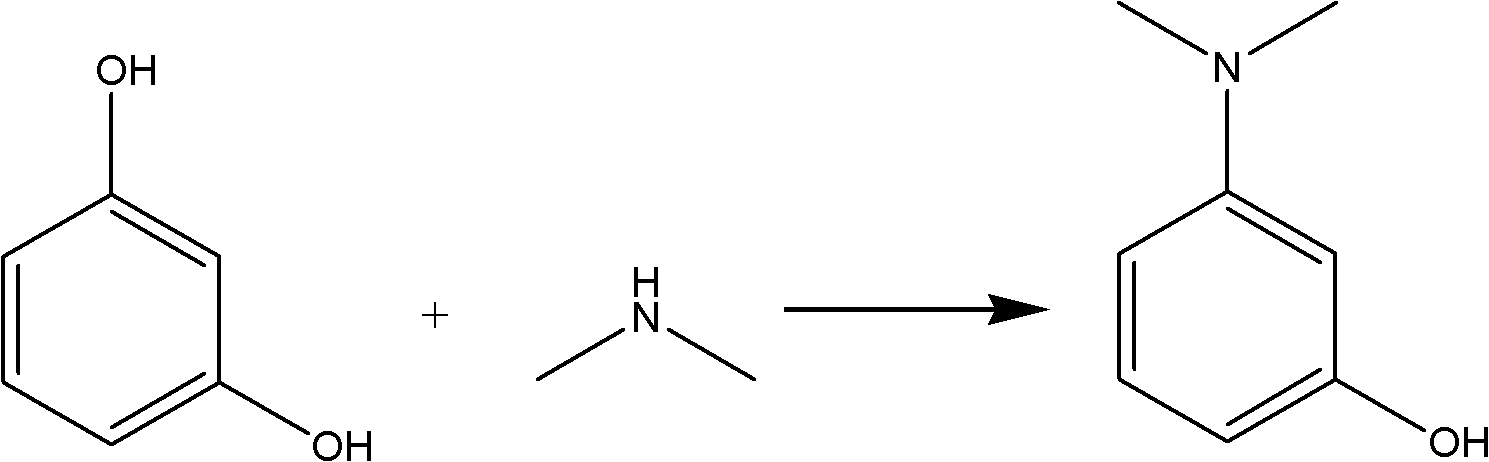

Preparation method of 3-(N,N-dimethylamino)phenol

A technology of dimethylamino and phenol, which is applied in the field of 3-phenol preparation, can solve the problems of high safety production and raw material transportation, unfavorable industrial production, etc., and achieve easy industrial safe production, easy storage and transportation, and high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] At room temperature, sequentially add 354g of resorcinol and 450g of dimethylamine aqueous solution with a mass percentage concentration of 36% into a 2L autoclave, heat up to 175°C, keep warm until the end of the reaction, and when the material cools down to 30°C after the reaction , transfer it to a 5L four-necked bottle, slowly add 1142g of industrial liquid caustic soda with a concentration of 30% by mass percentage under stirring, cool down to 20°C, extract impurities twice with 500ml of toluene, and adjust the pH of the water phase to 6~6 with industrial hydrochloric acid 7. Stand to separate the layers, discard the water layer, wash the oil layer twice with 500ml of hot water at a temperature of 80°C, then distill under reduced pressure to collect the main fraction as 3-(N,N-dimethylamino)phenol.

Embodiment 2

[0020] At room temperature, sequentially add 354g of resorcinol and 430g of dimethylamine aqueous solution with a mass percentage concentration of 40% into a 2L high-pressure reactor, raise the temperature to 180°C, and keep it warm until the reaction is complete. After the reaction, the material is cooled to 25°C , transfer it to a 5L four-necked bottle, slowly add 1100g of industrial liquid caustic soda with a mass percentage concentration of 35% under stirring, cool down to 15°C, extract impurities twice with 600ml toluene, and adjust the pH of the water phase with 20% dilute sulfuric acid 6-7, let stand to separate layers, discard the water layer, wash the oil layer twice with 550ml of hot water with a water temperature of 70°C, then distill under reduced pressure, and collect the main fraction as 3-(N,N-dimethylamino)phenol .

Embodiment 3

[0022] At room temperature, sequentially add 354g of resorcinol and 420g of dimethylamine aqueous solution with a concentration of 45% by mass into a 2L autoclave, heat up to 190°C, and keep warm until the reaction is over. After the reaction, the material cools down to 20°C , transfer it to a 5L four-necked bottle, slowly add 1120g of industrial liquid caustic soda with a mass percentage concentration of 36% under stirring, cool down to 30°C, extract impurities twice with 500ml of toluene, and adjust the pH of the water phase with 30% dilute sulfuric acid 6-7, let stand to separate, discard the water layer, wash the oil layer twice with 600ml of hot water at a temperature of 60°C, then distill under reduced pressure, and collect the main fraction as 3-(N,N-dimethylamino)phenol .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com