Itaconic acid glycidyl ester, and preparation method and application thereof

A technology of glycidyl ester and itaconic acid, applied in the field of epoxy resin and its preparation, to achieve the effects of enriching structure, saving resources and reducing dependence on petroleum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under nitrogen protection, 100 parts by weight of itaconic acid (Qingdao Langyatai Group Co., Ltd., purity greater than 99.5%), 700 parts by weight of epoxy bromopropane and 4 parts by weight of tetrabutylammonium bromide are fully mixed, and the ℃ for 5 hours, then cooled to 60 ℃, added 30 parts by weight of sodium hydroxide and 100 parts by weight of deionized water to form a reaction system, continued to react for 2 hours, after the reaction system dropped to room temperature, added 150 parts by weight of deionized water each time Ionized water was used to wash for 4 times in total. Then remove the solvent with a rotary evaporator, and dry it in vacuum at 50° C. for 12 hours to obtain 152 parts by weight of glycidyl itaconate

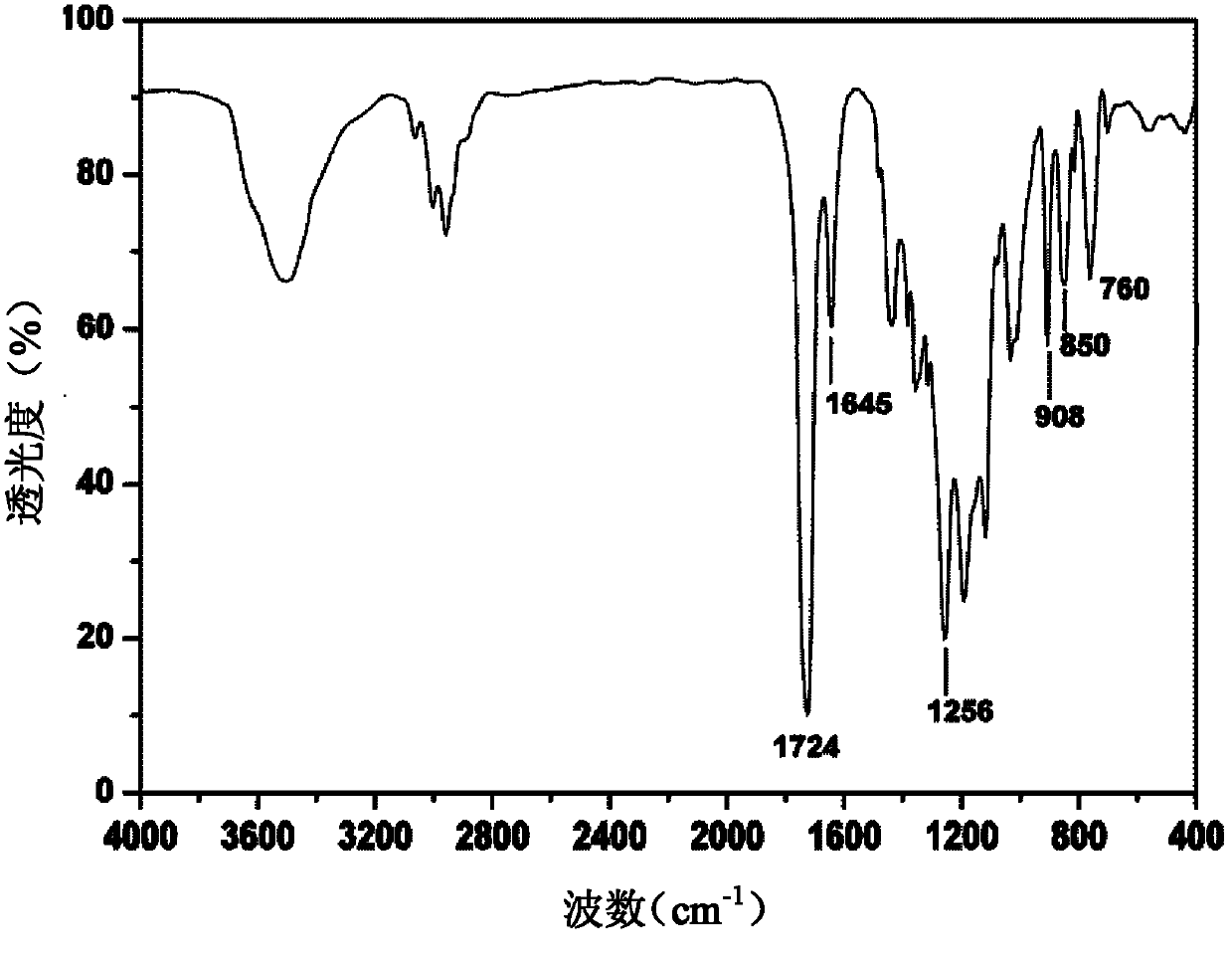

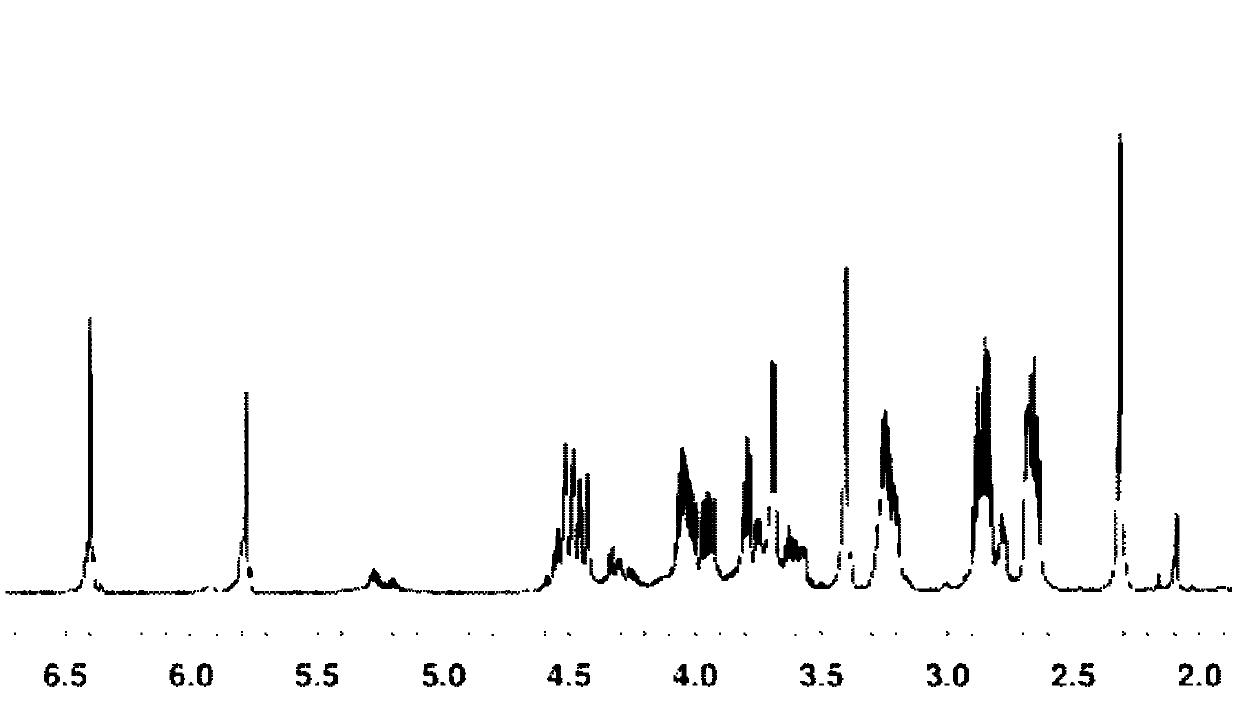

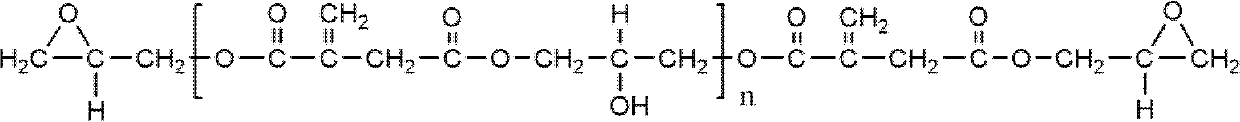

[0038] Glycidyl itaconate prepared above is carried out structural characterization, and its infrared spectrogram is as follows figure 1 As shown, the hydrogen NMR spectrum is shown as figure 2 Shown, is the compound of formula I structure....

Embodiment 2

[0044] Under nitrogen protection, 100 parts by weight of itaconic acid (Qingdao Langyatai Group Co., Ltd., purity greater than 99.5%), 200 parts by weight of epoxybromopropane and 2 parts by weight of cetyltrimethylammonium bromide are fully Mix and react at 140°C for 3 hours, then lower the temperature to 70°C, add 50 parts by weight of potassium hydroxide and 50 parts by weight of deionized water to form a reaction system, and continue to react for 5 hours. After the reaction system drops to room temperature, add 200 parts by weight of deionized water were used for washing for 3 times in total. Then, the solvent was removed by a rotary evaporator, and vacuum-dried at 50° C. for 12 hours to obtain 102 parts by weight of glycidyl itaconate.

[0045] The structure of the glycidyl itaconate prepared above was characterized, and its infrared spectrum and proton magnetic resonance spectrum were basically consistent with those in Example 1, and it was a compound with the structure ...

Embodiment 3

[0051] Under nitrogen protection, 100 parts by weight of itaconic acid (Qingdao Langyatai Group Co., Ltd., purity greater than 99.5%), 800 parts by weight of epoxy chloropropane and 15 parts by weight of tetramethylammonium chloride are fully mixed, and ℃ for 5 hours, then cooled to 60 ℃, added 50 parts by weight of lithium hydroxide and 100 parts by weight of deionized water to form a reaction system, continued to react for 3 hours, after the reaction system dropped to room temperature, added 180 parts by weight of deionized water each time Ionized water was used to wash for 3 times in total. Then, the solvent was removed by a rotary evaporator, and vacuum-dried at 50° C. for 12 hours to obtain 132 parts by weight of glycidyl itaconate.

[0052] The structure of the glycidyl itaconate prepared above was characterized, and its infrared spectrum and proton magnetic resonance spectrum were basically consistent with those in Example 1, and it was a compound with the structure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com