Weft yarn extension dynamic state measuring system

A technology of dynamic measurement and length measurement, used in textiles, textiles and papermaking, looms, etc., can solve the problem of not being able to understand the characteristics of weft yarns in motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

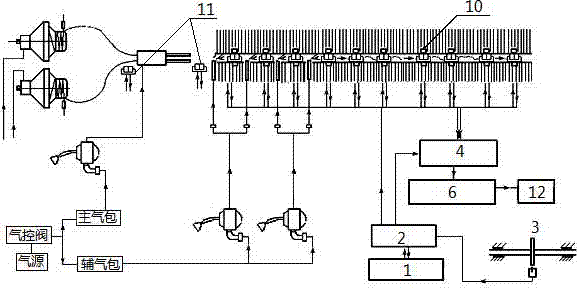

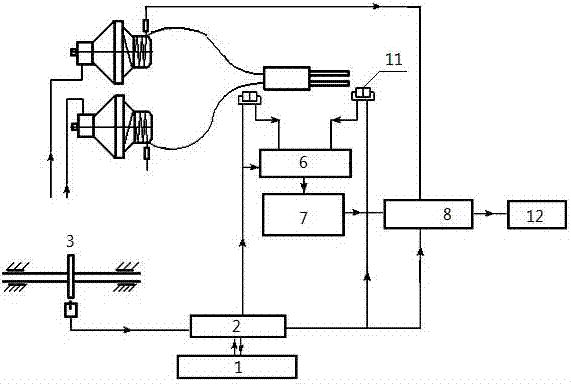

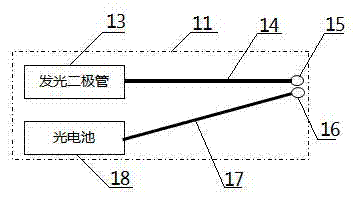

[0025] see figure 1 , figure 2 As shown, a weft yarn elongation dynamic measurement system includes a loom control system 1, a main control board 2 and a high-resolution encoder 3, and the high-resolution encoder 3 is connected to the main control board 2, and the main control board 2 is connected to the main control board 2. The control board 2 is connected to the loom control system 1, and also includes a weft yarn arrival length measurement system and a weft yarn delivery length measurement system, and the weft yarn arrival length measurement system includes several sets of detectors 9 evenly distributed along the reed width. Photoelectric sensors 10 are respectively installed on several sets of detectors 9, described several sets of photoelectric sensors 10 are connected to a time data acquisition analyzer 4 in turn, and the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com