Automatic emptying and swabbing measuring tank

An automatic emptying and metering tank technology, which is applied in the direction of wellbore/well components, earthwork drilling and mining, etc., can solve the problems of manual cleaning of square tanks such as heavy workload, incomplete cleaning, and inability to empty in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

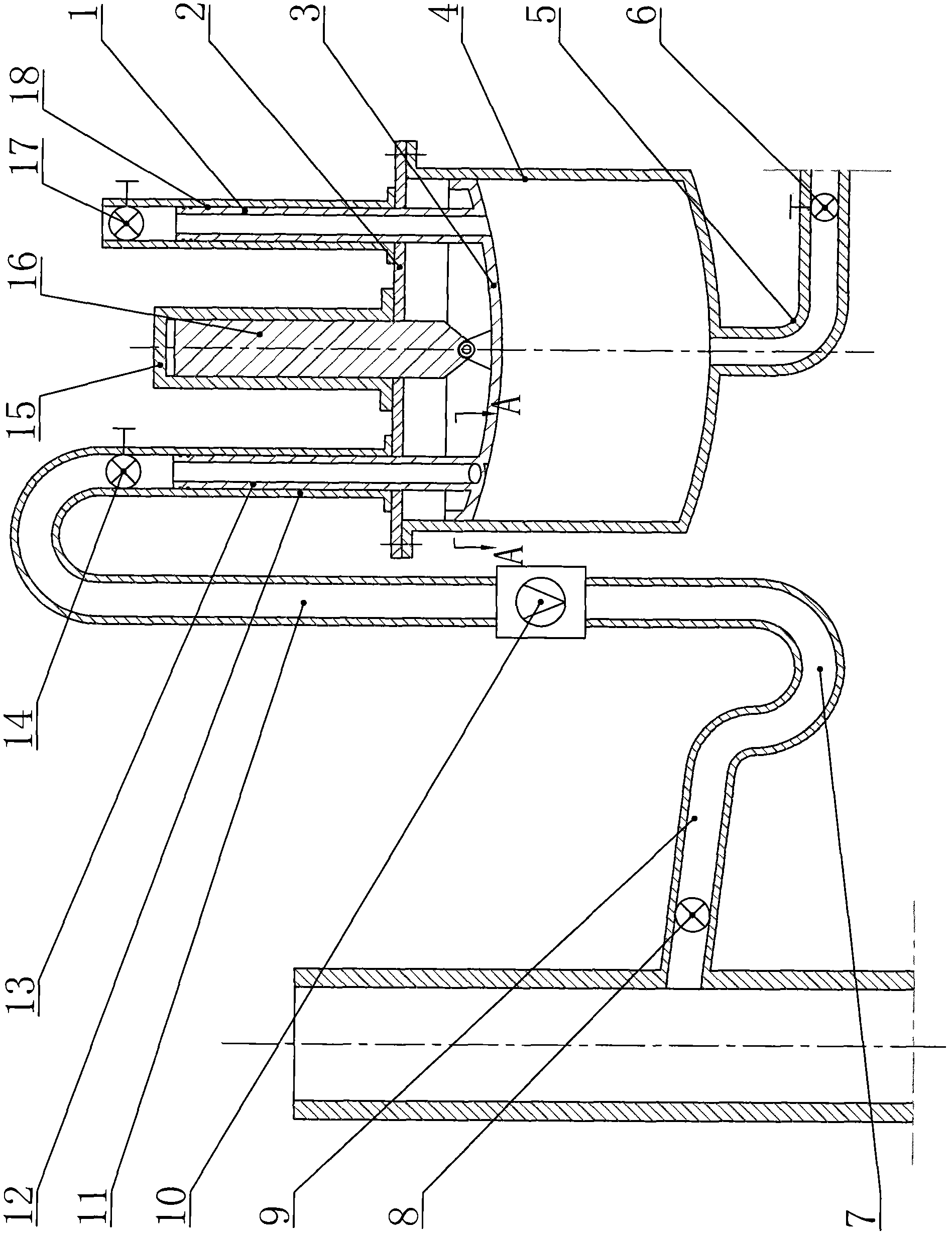

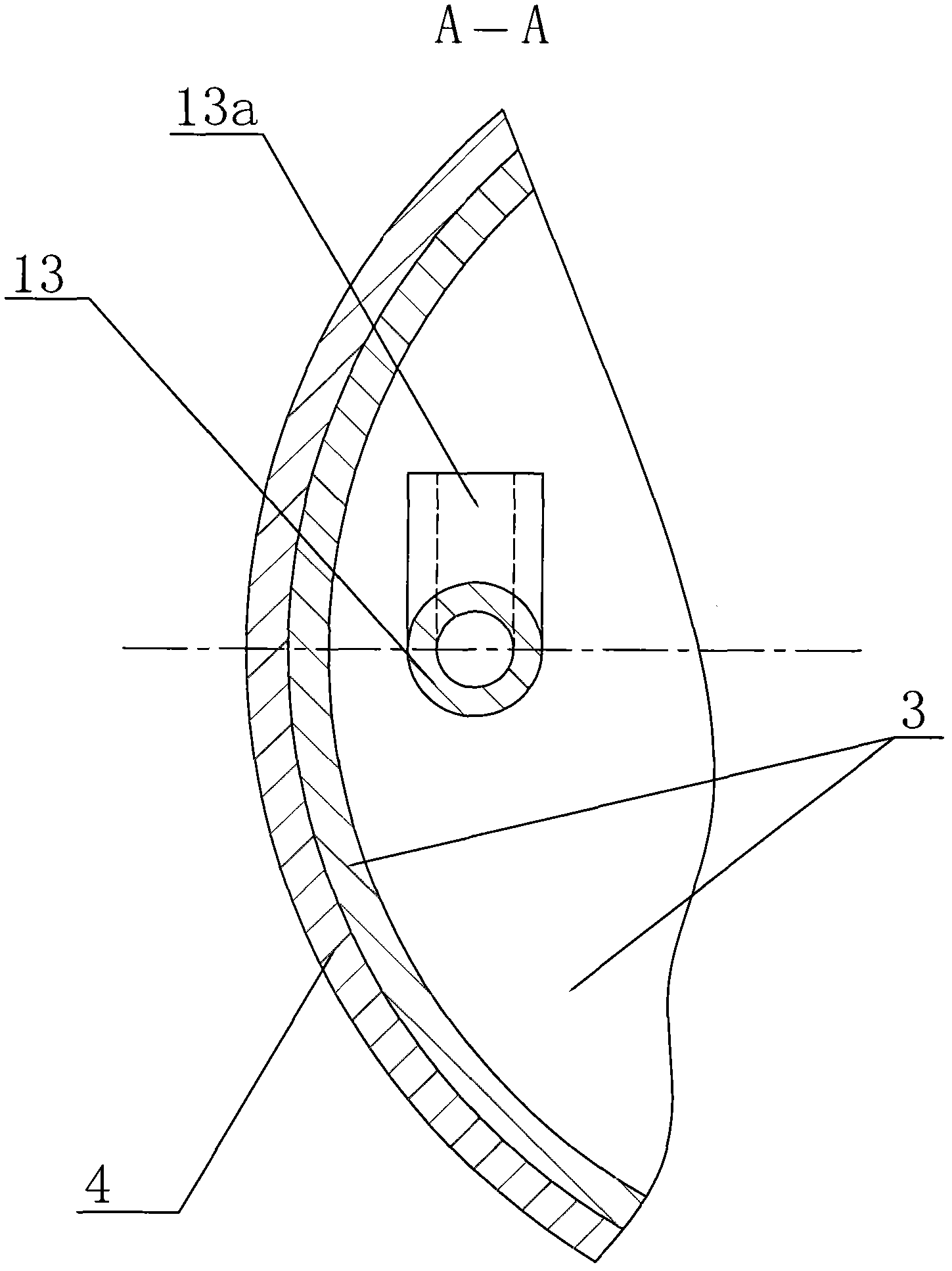

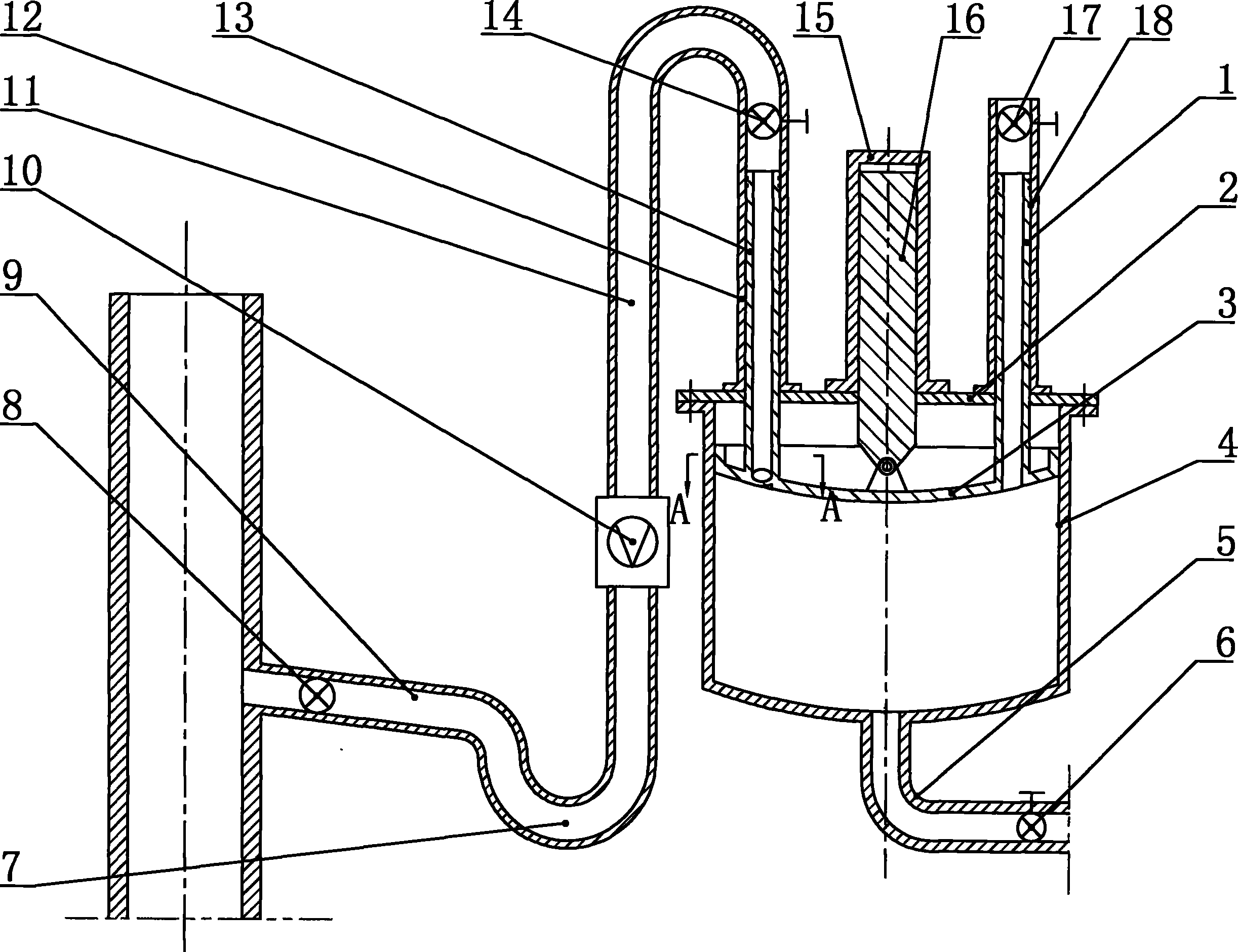

[0013] As shown in the figure, it is an automatic emptying pumping metering tank, including a liquid inlet line connected to the wellhead liquid discharge pipe 5, and the liquid inlet line includes an initial pipe section 9 provided with a balanced air intake valve 8, and the initial pipe section 9 and The effusion pipe sections are connected, the end of the effusion pipe section is connected to the vertical pipe section 11, and the end of the vertical pipe section 11 is connected to the liquid inlet sleeve 12; the vertical pipe section 11 is provided with a flowmeter 10; the initial pipe section 9 is from the balance inlet valve 8 to the accumulator The liquid pipe section is gradually inclined downward; the effusion pipe section is an effusion elbow 7, which can also be an effusion tank; the bottom of the tank body 4 is provided with a drain pipe 5, and the drain pipe 5 is provided with an emptying valve 6; The end of the liquid pipeline is provided with a liquid inlet sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com