Continuous variable cross-section tunnel lining formwork trolley

A formwork trolley and variable-section technology, which is applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of inability to apply to different sections and large construction costs, and achieve good economic benefits and reduce construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

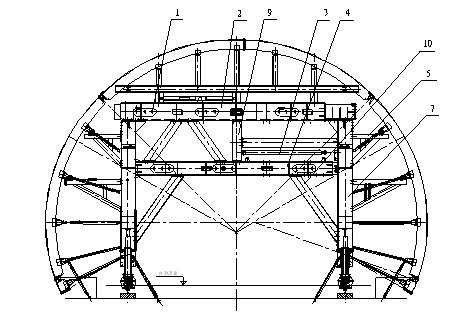

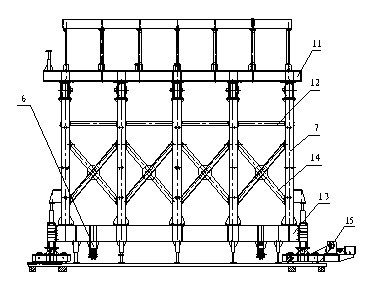

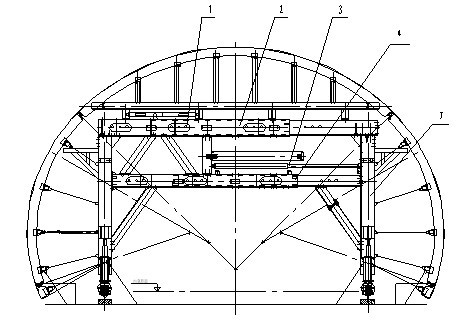

[0012] Embodiment of the present invention: the continuously variable cross-section tunnel lining formwork trolley includes a formwork system, a gantry system, a traveling device, a support mechanism and a hydraulic system, and the gantry system includes a gantry beam 2, a gantry moving cylinder 3, and a gantry middle beam 4. Side mold positioning bracket 5, lateral moving wheel 6, column 7, the two ends of the door frame moving cylinder 3 are respectively connected to the column 7 and vertical support 9, the side mold positioning bracket 5 is connected to the outside of the column 7, and the lateral moving wheel 6 is arranged on the lower beam 13; in the cross section of the trolley, the upright columns 7 on both sides are respectively connected by the mast beam 2 and the mast middle beam 4; The beam 11, the middle beam 12, and the lower beam 13 are connected, and a cross brace 14 is arranged between the adjacent columns 7, and the walking system 15 is connected with the colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com