Chain tensioner device

A chain tensioning device, chain technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

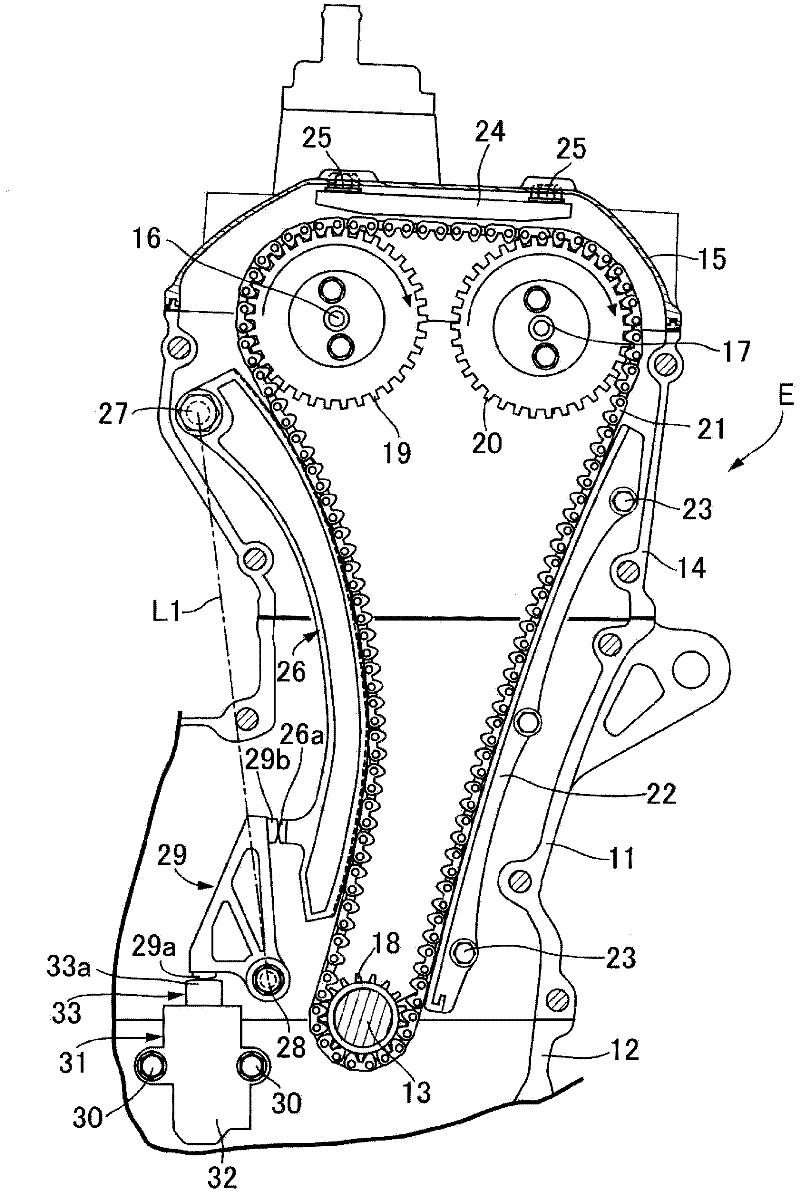

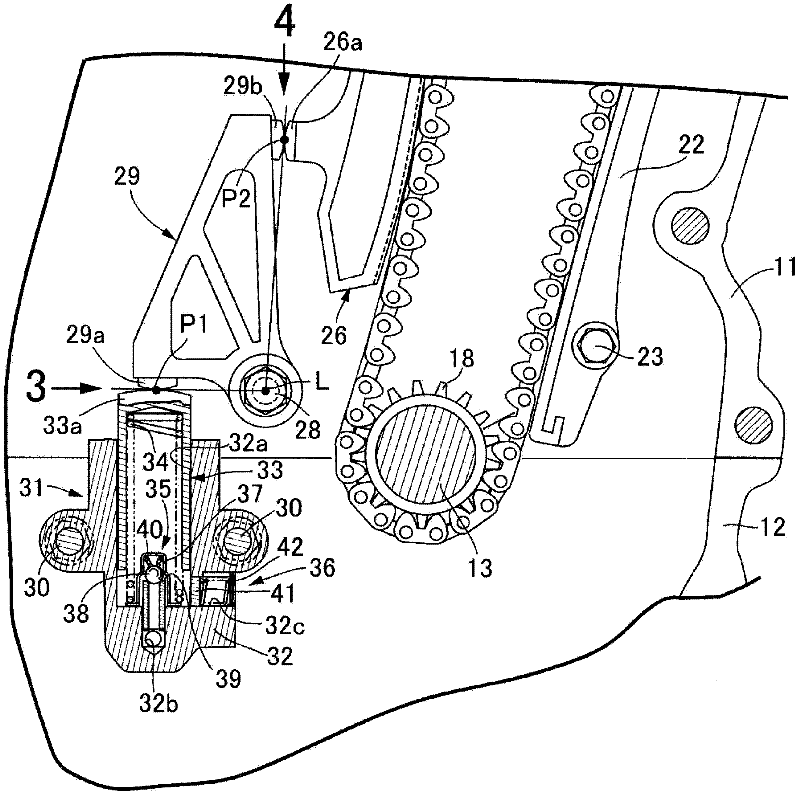

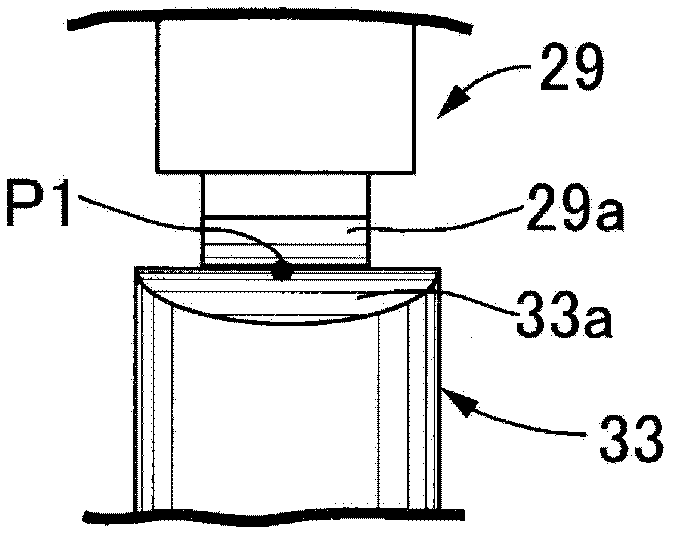

[0038] like figure 1 As shown, a crankshaft 13 is rotatably supported between a cylinder block 11 of the engine E and a crankcase 12 coupled to the lower surface of the cylinder block. In addition, an intake camshaft 16 and an exhaust camshaft are rotatably supported between the cylinder head 14 coupled to the upper surface of the cylinder block 11 and the cylinder head cover 15 coupled to the upper surface of the cylinder head 14. 17. On the driving sprocket 18 provided at the shaft end of the crankshaft 13 and the two driven sprockets 19 and 20 respectively provided at the shaft ends of the intake camshaft 16 and the exhaust camshaft 17, a chain consisting of an endless chain is wound. The timing chain 21 , the intake camshaft 16 and the exhaust camshaft 17 are driven at one-half the rotational speed of the crankshaft 13 .

[0039] The first fixed chain guide 22 is in sliding contact with the chord of the tight side of the timing chain 21 between the drive sprocket 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com