Method and system for testing novel contra-rotating dual-rotor motor driver

A dual-rotor motor and testing system technology, applied to instruments, measuring electronics, measuring devices, etc., can solve problems such as differences in test results, inability to record data in real time, blank test equipment, etc., and achieve accurate and effective characteristic testing, which is conducive to accurate testing , The effect of facilitating human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

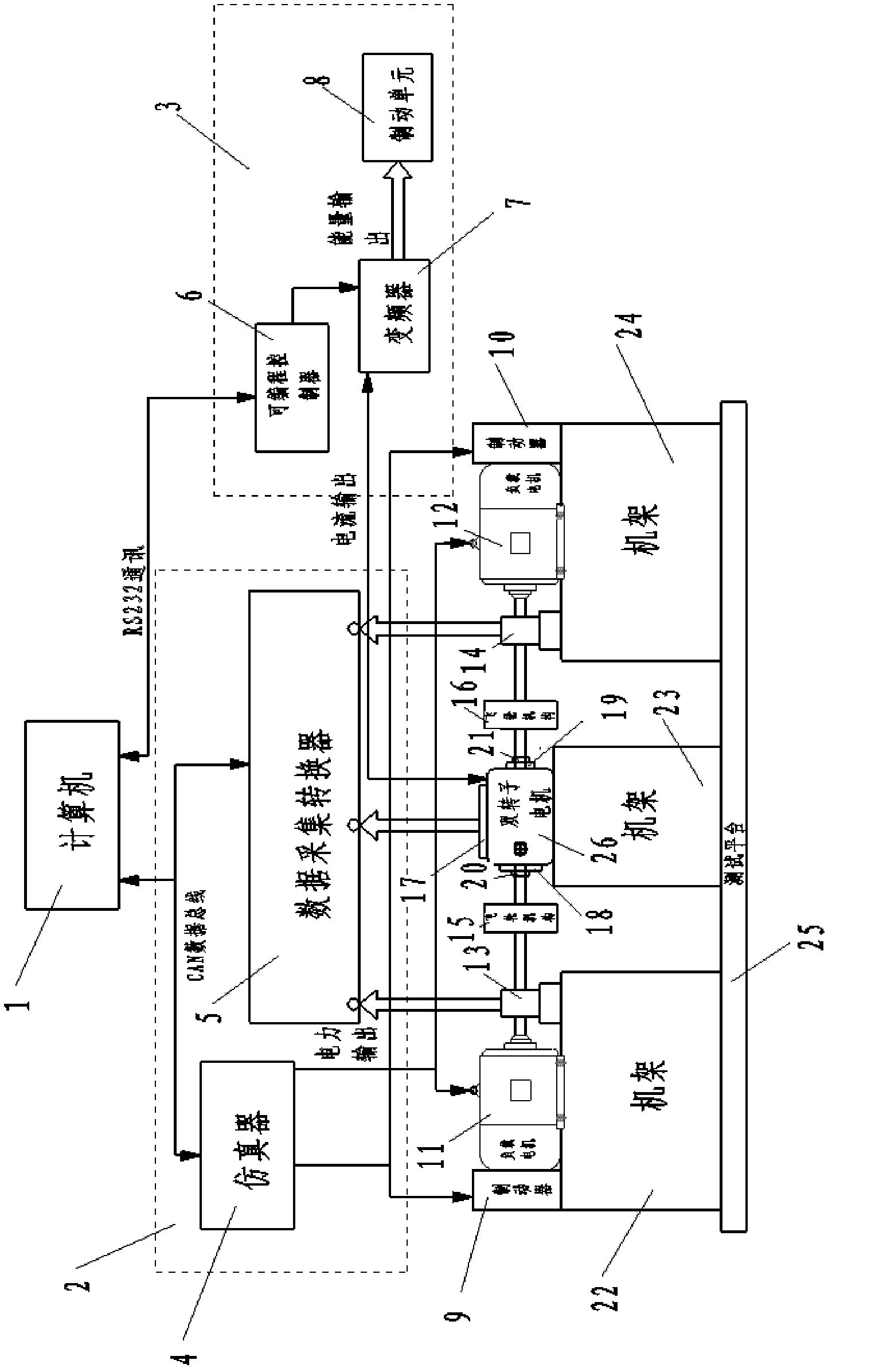

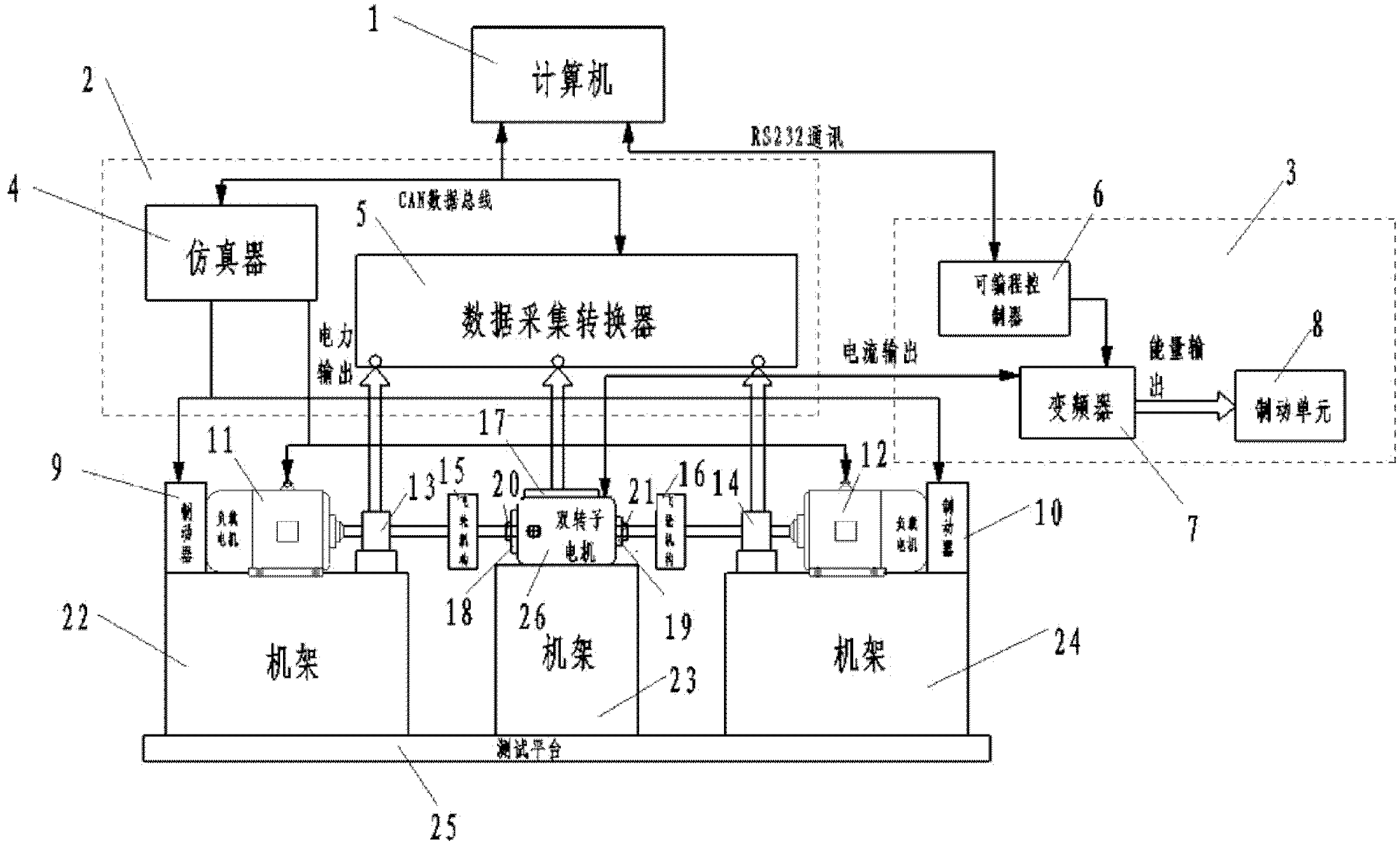

[0036] A test system of the present invention aimed at testing a new type of electric vehicle drive system-a counter-rotating double-rotor motor driver is closely combined with a bench mechanism part and a control part.

[0037] The platform mechanism part includes a counter-rotating double-rotor motor 26, left and right deceleration (reversing) mechanisms 18, 19, left and right universal transmission mechanisms 20, 21, supporting and fixing devices, testing devices, working condition parameter detection sensor groups 5, and left and right brakes 9 , 10. The double-rotor motor 26 is composed of an outer rotor and an inner rotor with winding windings. The outer rotor is connected to the test device and the brake 10 on one side through the reduction mechanism 19 and the universal transmission mechanism 21 on one side; the inner rotor passes through the other side in turn. The deceleration and reversing mechanism 18 and the universal transmission mechanism 20 are connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com