High-low temperature test chamber

A technology for high and low temperature test chambers and chamber doors, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of increasing test costs and relatively large temperature fluctuations, and achieve the goals of reducing test costs, preventing steam frosting, and prolonging life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

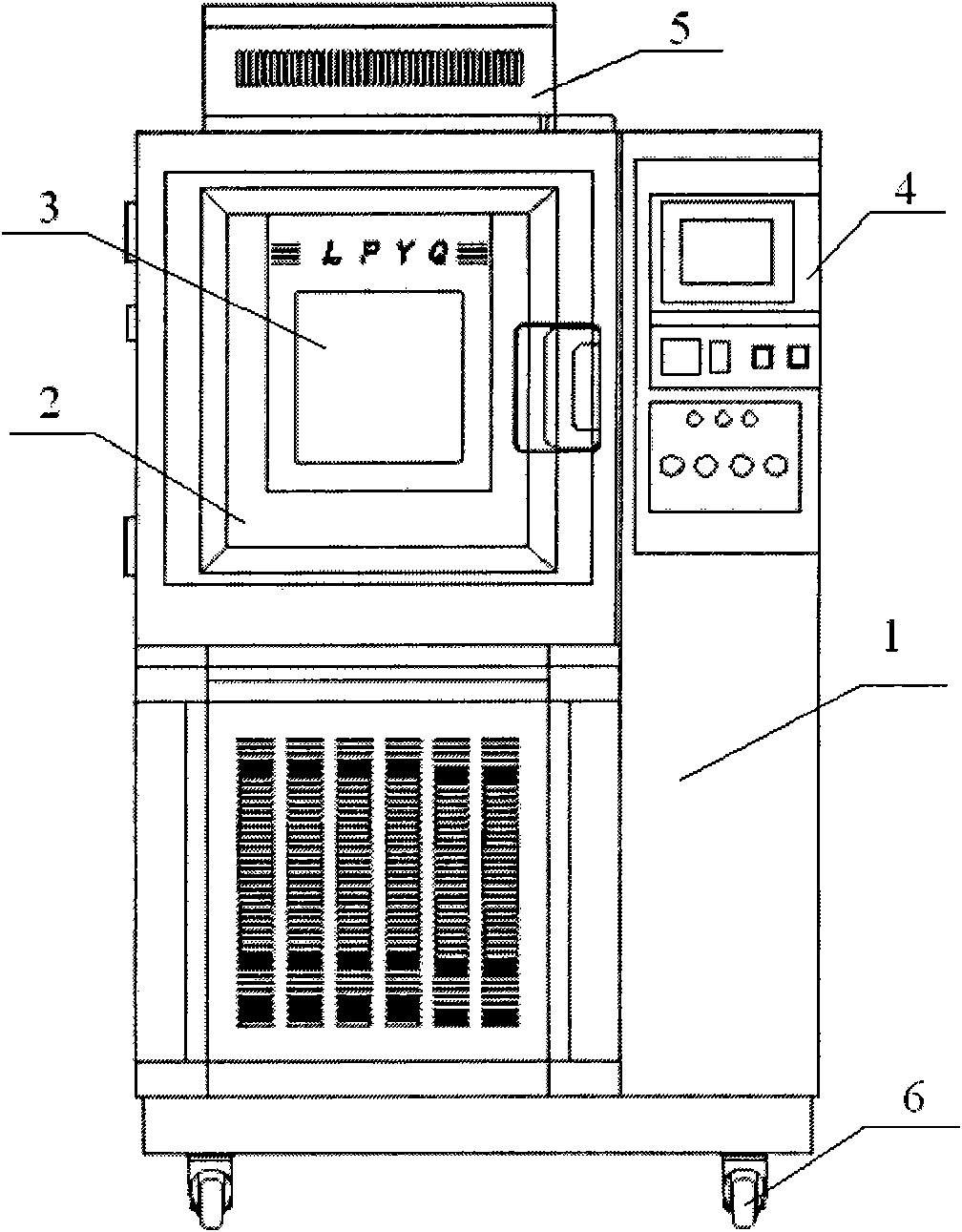

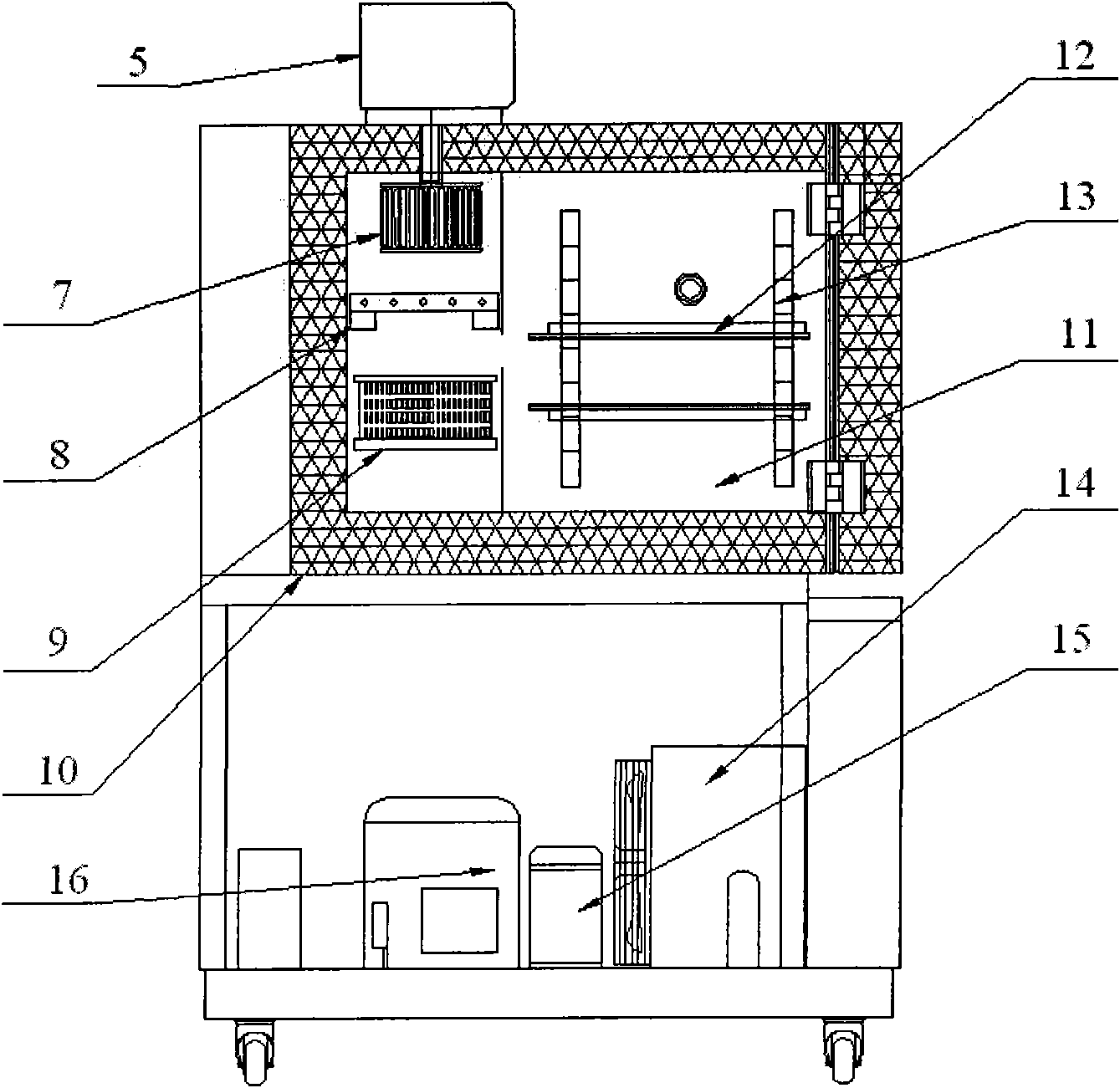

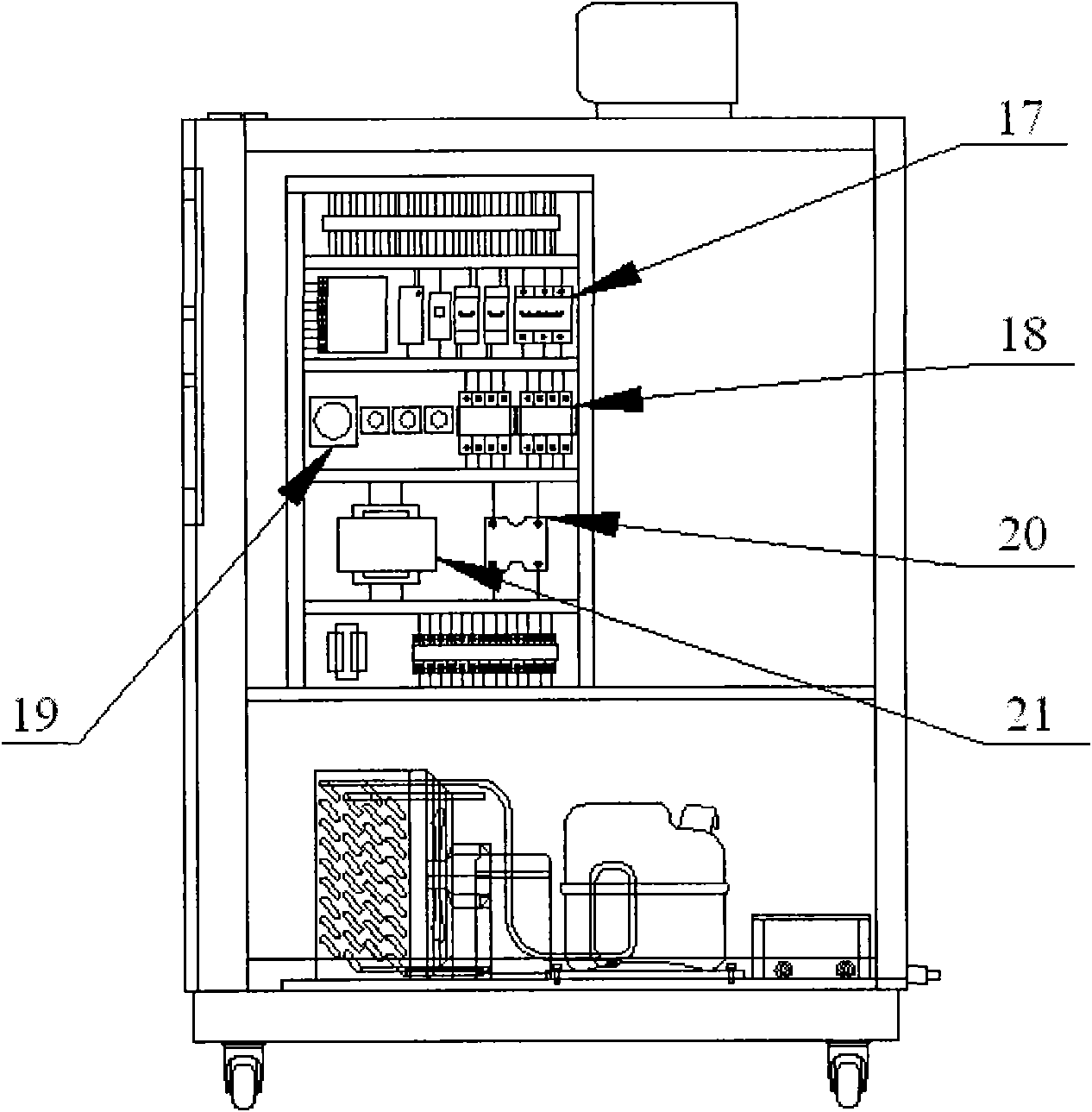

[0020] A kind of high and low temperature test box, its structure is as follows Figure 1~3 As shown, the test chamber includes a housing 1, a heating wire 8, a working chamber 11, a refrigeration system and an electrical system. An open door 2 is arranged on the front of the housing 1, and the door 2 is connected to the housing 1 through a hinge. An observation window 3 is arranged on the door 2, and a control instrument 4 is arranged on the right side. Shell 1 is obtained by sheet metal processing. The outer tank material is made of high-quality A3 steel plate (t=1.2mm) and processed by CNC machine tools. The surface of the outer shell is sprayed with plastic to make it more clean and beautiful. The inner tank material is imported (SUS304) High quality mirror finish stainless steel plate. The blower 5 is arranged on the top of the casing 1, and the universal caster 6 is arranged on the bottom, so as to facilitate the movement of the test chamber. Working room 11, refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com