Twisting machine

A twisting machine and frame technology, applied in the field of cable or cable processing equipment, twisting machine, can solve the problems of unstable tension, cable damage, low work efficiency, etc., to achieve good transmission stability and quality assurance Reliability and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

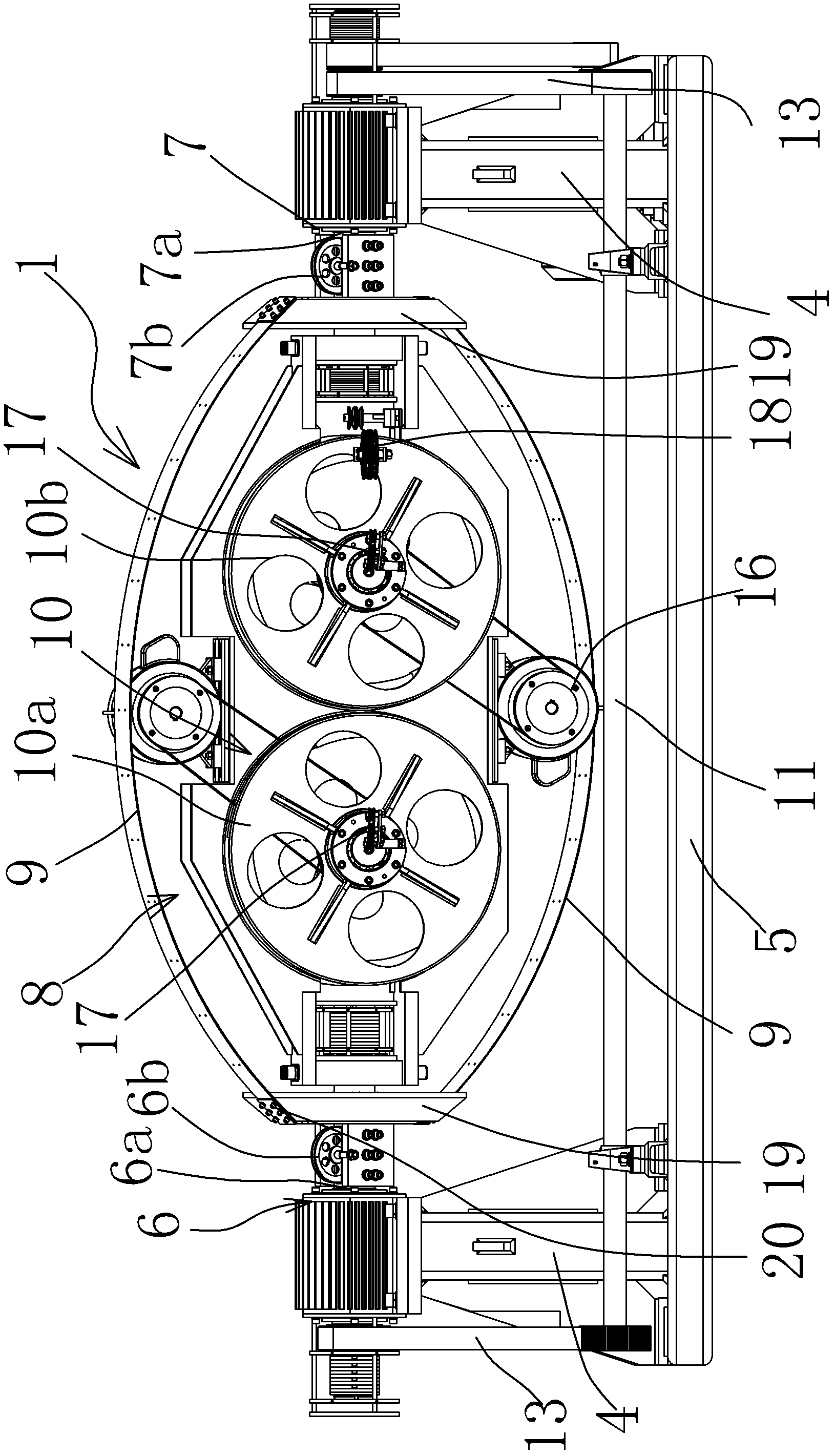

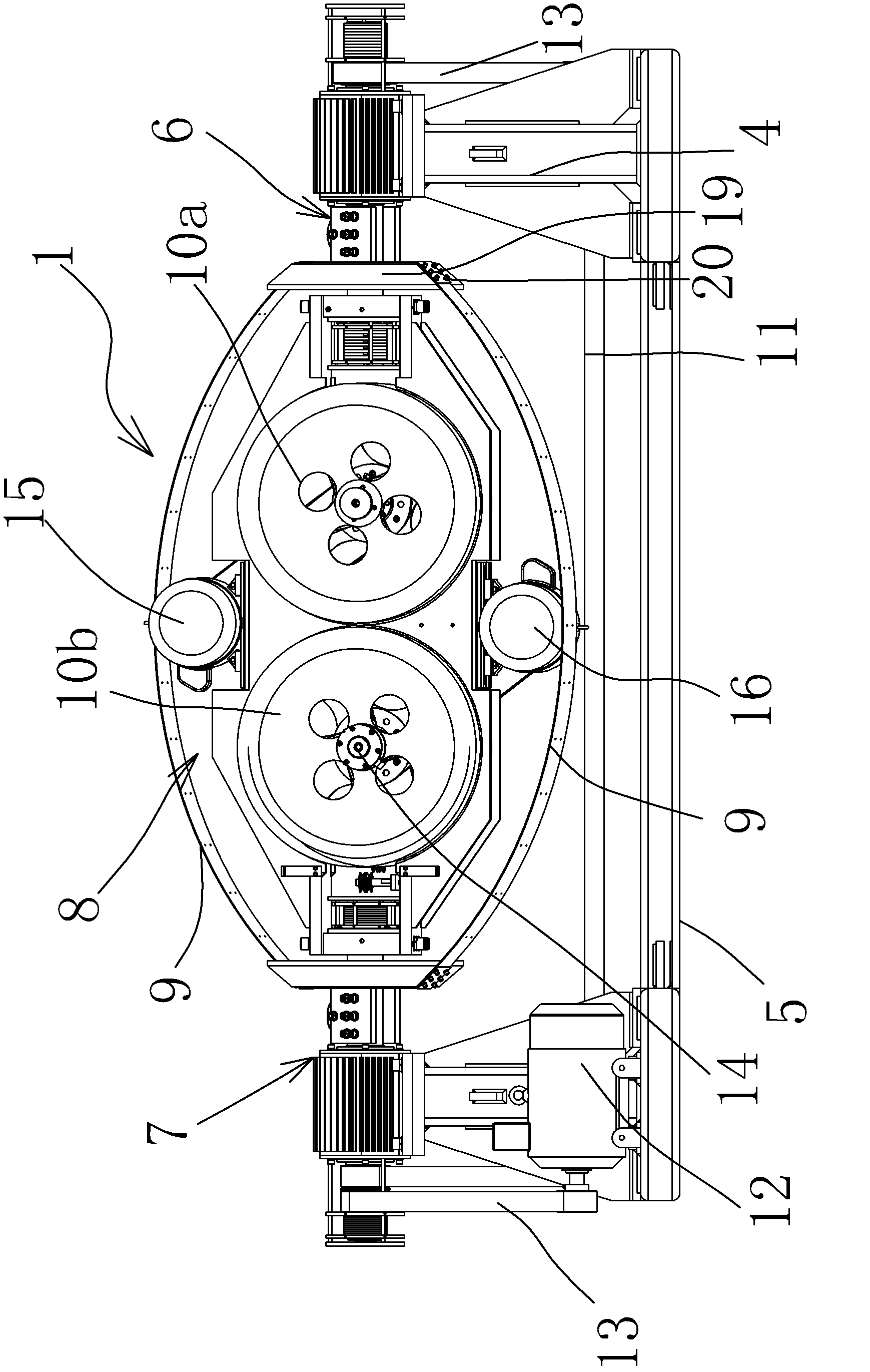

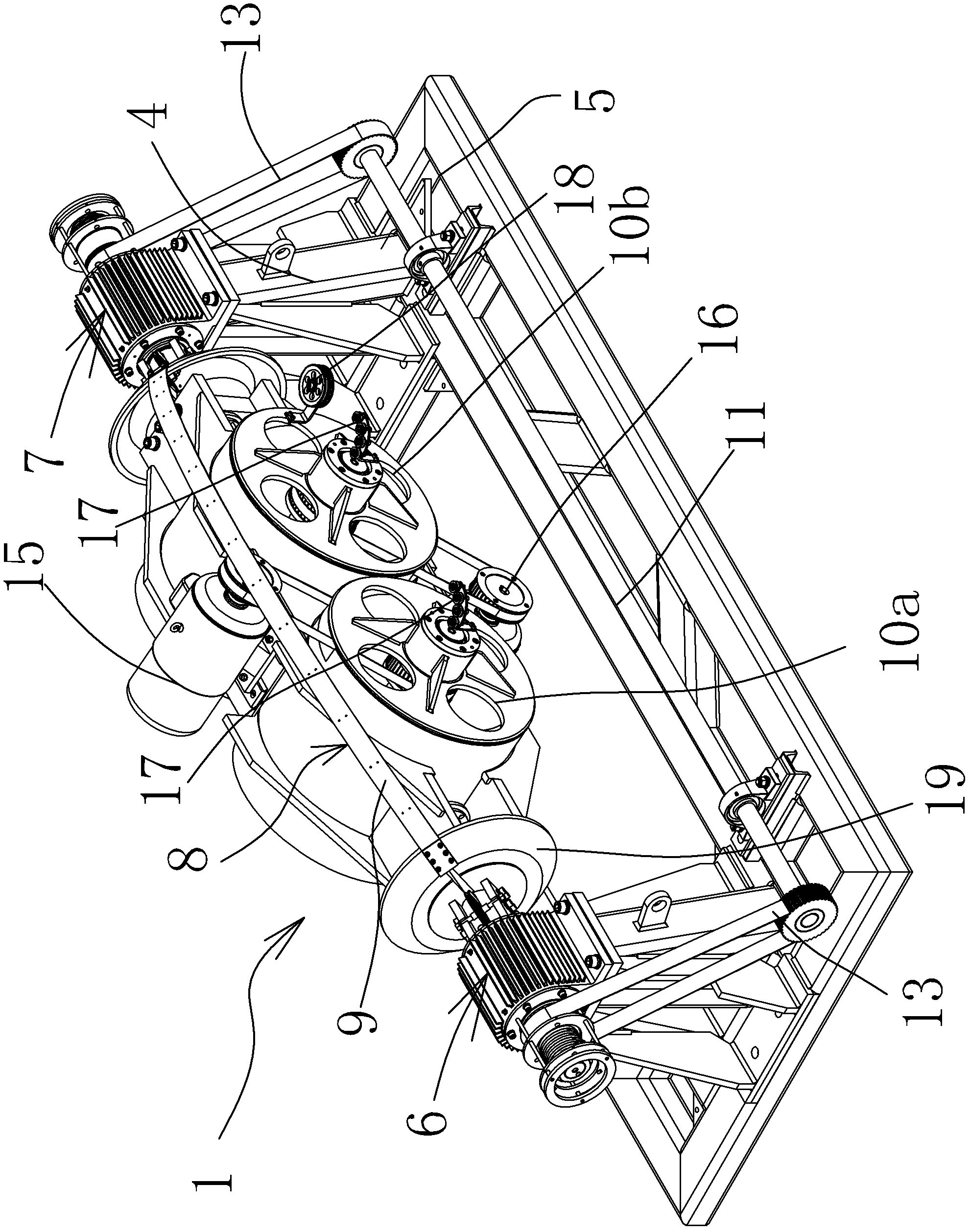

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0026] In the figure, the pay-off mechanism 1; the take-up mechanism 2; the lifting part 3; the frame 4; the base 5; the front main shaft part 6; the front main shaft 6a; the front guide wheel 6b; the rear main shaft part 7; the rear main shaft 7a; the rear guide wheel 7b; first cradle assembly 8; twisted bow 9; pay-off reel 10; first pay-off reel 10a; second pay-off reel 10b; synchronous shaft 11; transmission motor 12; Motor 15; second pay-off motor 16; outgoing line traction wheel 17; guide wheel 18; twisted pair disc 19; pressing sheet 20; incoming line main shaft part 21; incoming line main shaft 21a; incoming line guide wheel 21b; outgoing line main shaft part 22 Outlet main shaft 22a; Outlet guide wheel 22b; Second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com