Silicon microphone and packaging structure of product applying same

A technology of silicon microphone and packaging structure, which is applied in the direction of sensors, electrostatic transducers, microphones, electrical components, etc., can solve the problems of MEMS chip work interference and affect the sound pickup effect of silicon microphones, and achieve the effect of noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

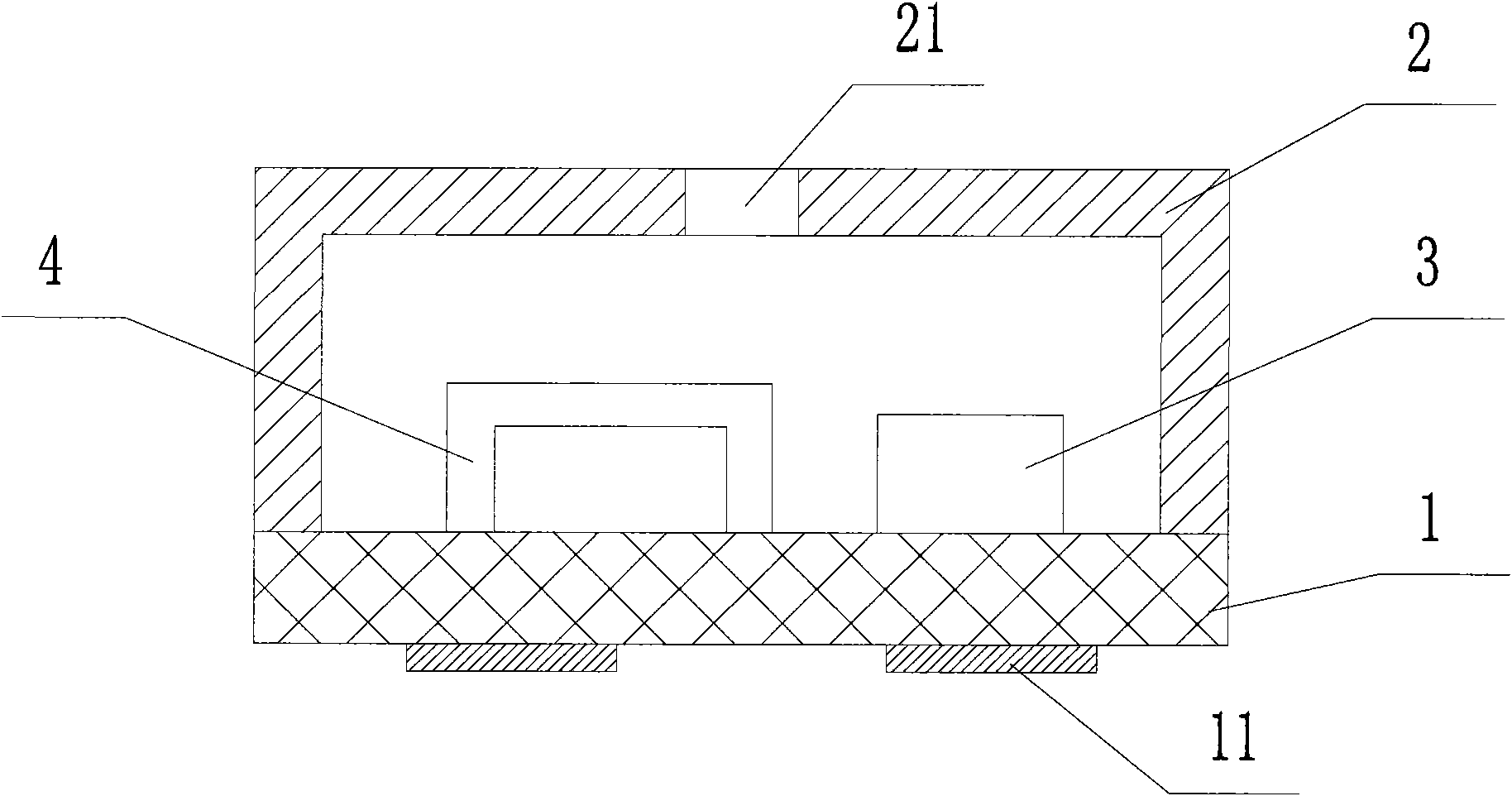

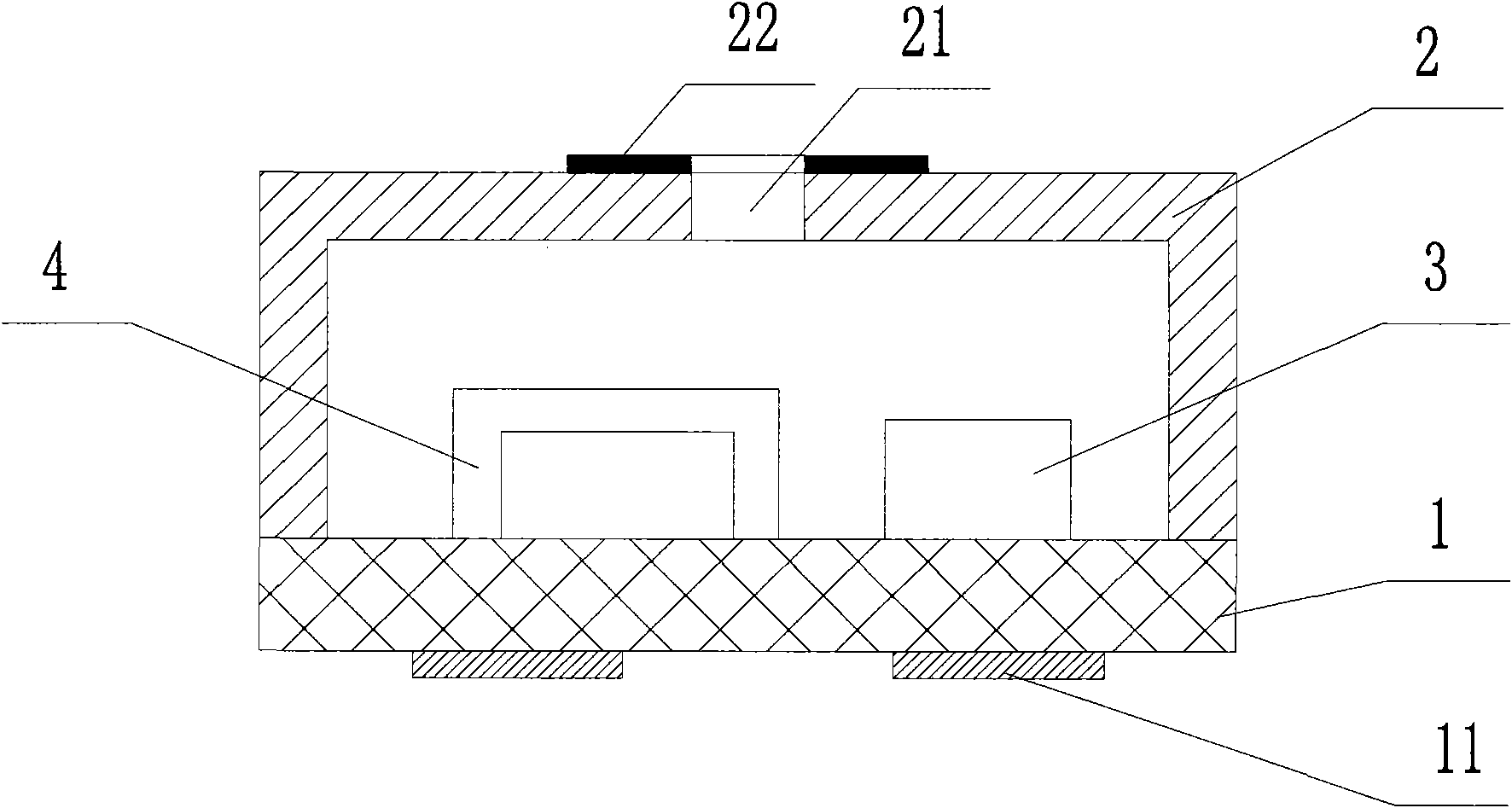

Embodiment 1

[0030] image 3 with Figure 4 It is a schematic cross-sectional structure diagram and a plan view of Embodiment 1 of the present invention. Such as image 3 , Figure 4 As shown, in Embodiment 1, a square circuit board 1 and a square metal shell 2 constitute the external package of the silicon microphone, and the metal shell 2 is provided with a sound hole 21 for receiving external sound signals, and the circuit board inside the package 1, IC chip 3 and MEMS chip 4 are installed respectively, wherein MEMS chip 4 is made by utilizing MEMS (micro-electro-mechanical system) technology, and can convert external sound signals into electrical signals, and the electrodes of MEMS chip 4 and circuit board 1 The IC chip 3 is electrically connected, and finally the electrical signal processed by the IC chip is transmitted to the outside of the silicon microphone through a plurality of pads 11 provided on the outer surface of the circuit board 1 and connected to the external circuit. ...

Embodiment 2

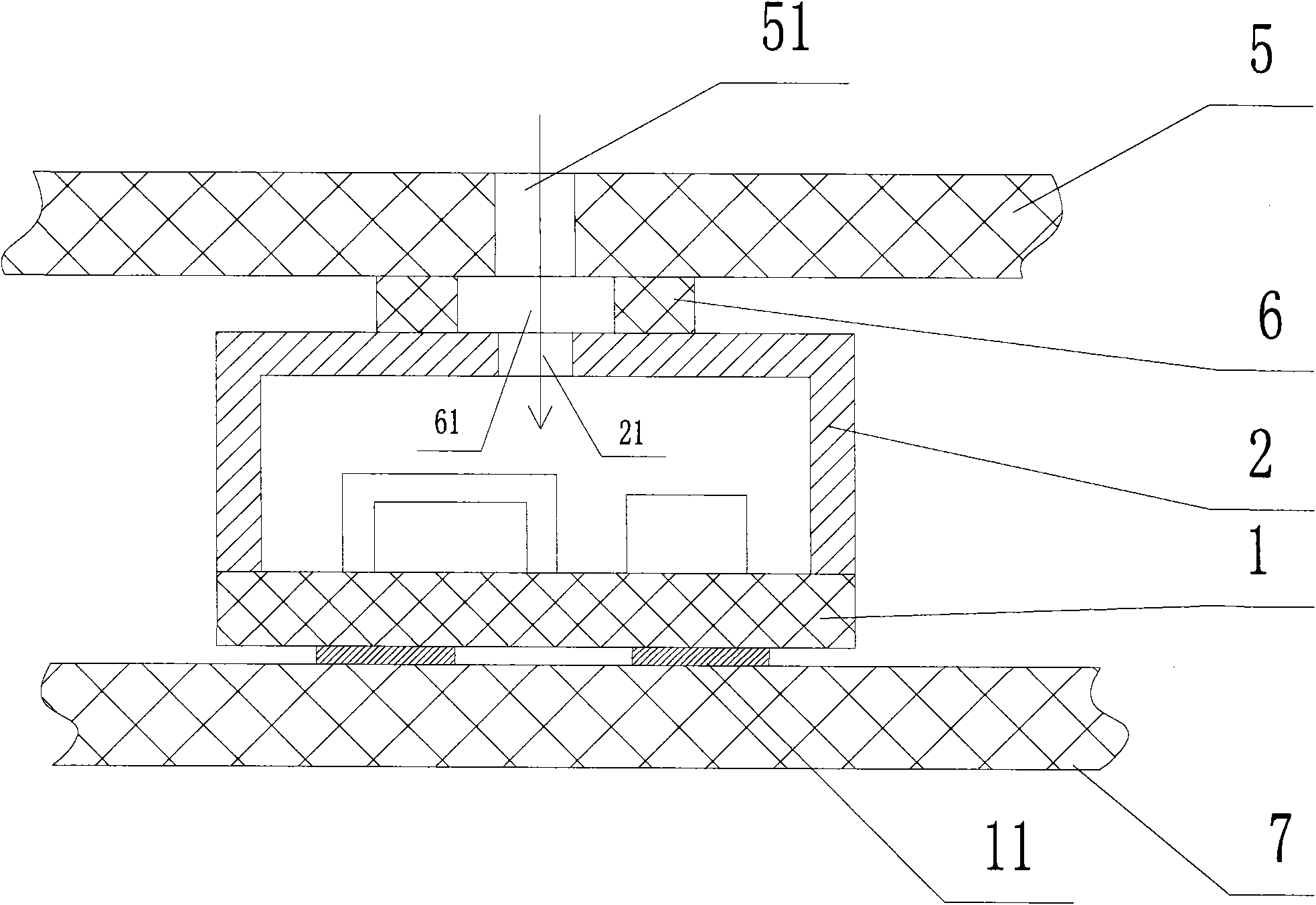

[0039] Image 6 with Figure 7 They are a schematic cross-sectional structure diagram and a top view of Embodiment 2 of the present invention, respectively. Such as Image 6 , Figure 7 As shown, in the second embodiment, a square circuit board 1 and a square metal shell 2 constitute the external package of the silicon microphone, and the metal shell 2 is provided with a sound hole 21 for receiving external sound signals, and the circuit inside the package On board 1, IC chip 3 and MEMS chip 4 are installed respectively, wherein MEMS chip 4 is to utilize MEMS (micro-electro-mechanical system) technology to make, can convert external sound signal into electric signal, the electrode of MEMS chip 4 and circuit board 1 The IC chip 3 on the circuit board 1 is electrically connected, and finally the electrical signal processed by the IC chip is transmitted to the outside of the silicon microphone through a plurality of pads 11 provided on the outer surface of the circuit board 1 ...

Embodiment 3

[0044] Figure 8 with Figure 9 It is a schematic cross-sectional structure diagram and a bottom view of Embodiment 3 of the present invention, respectively.

[0045] Such as Figure 8 with Figure 9 As shown, similar to the previous embodiment, the silicon microphone of the third embodiment also consists of a square circuit board 1 and a square metal casing 2 to form an external package, and IC chips 3 are respectively installed on the circuit board 1 inside the package. And MEMS chip 4, wherein MEMS chip 4 is to utilize MEMS (micro-electromechanical system) technology to make, can convert the external sound signal into electric signal, the electrode of MEMS chip 4 is electrically connected with IC chip 3 on the circuit board 1, and finally The electrical signal processed by the IC chip is transmitted to the outside of the silicon microphone through a plurality of pads 11 provided on the outer surface of the circuit board 1 and connected to an external circuit.

[0046] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com