Control method of generating overheat steam by electric steaming furnace

A superheated steam and control method technology, which is applied to auxiliary controllers with auxiliary heating devices, temperature control using electric methods, steam cooking utensils, etc., can solve the problems of wasted energy and time-consuming, etc., and achieve improvement The effect of speed, expansion of contact area, and improvement of cooking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

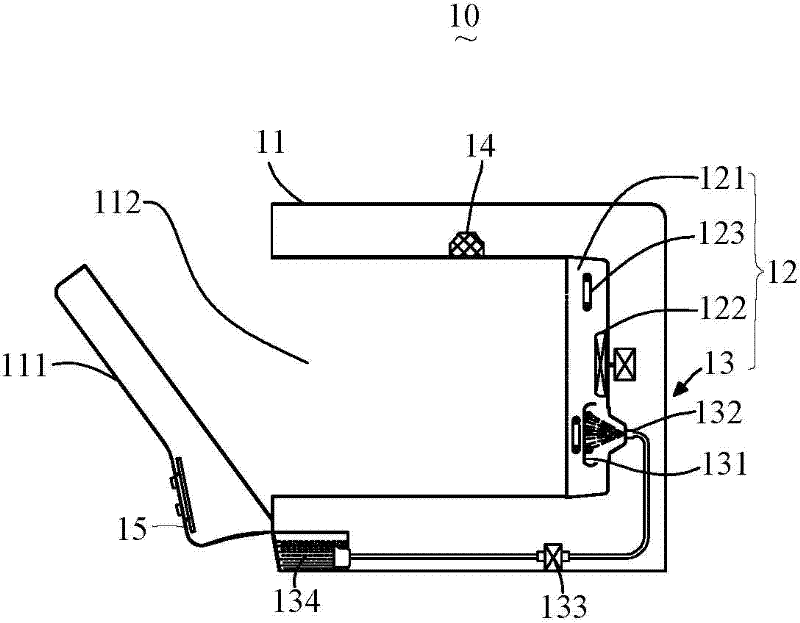

[0052] see figure 1 The shown electric steam oven 10 adopting the method for controlling the superheated steam generated by the electric steam oven according to the present invention includes a furnace body 11 , a superheated steam supply device 12 and an electric control device 15 . The superheated steam supply device 12 is provided on one side of the furnace body 11 .

[0053] The furnace body 11 includes a door 111 for sealing the furnace body and a cooking chamber 112 formed after the furnace body is sealed. The cooking chamber 112 is provided with a temperature sensor 14 for detecting the temperature of the cooking chamber, and the temperature sensor 14 is arranged on the top of the cooking chamber 112 .

[0054] The superheated steam supply device 12 includes a superheated chamber 121 , a fan 122 installed in the superheated chamber 121 , a dry burner 123 and a steam generating device 13 . The steam generating device 13 includes a heating element 131 , an atomizing dev...

Embodiment approach 2

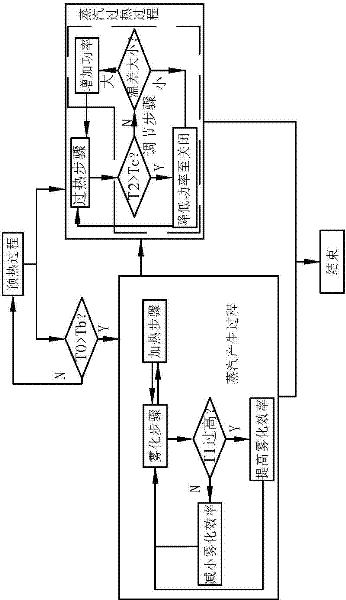

[0071] see Figure 4 The second embodiment of the method for controlling superheated steam generated by an electric steamer according to the present invention differs from the first embodiment in that the control of the superheated steam generated by the electric steamer also includes an electric control device detecting the temperature of the heated steam T 1 and with the preset temperature T s Compare that when the temperature T 1 greater than the preset temperature T s At this time, the fan 122 is driven to work.

[0072] Thus, when the temperature T 1 Preset temperature T not reached s At this time, the heated steam has a preheating effect on the electric steamer; when the temperature T 1 Reach or exceed the preset temperature T s At this time, start the fan to ensure the heating speed of the heated steam, and prevent the colder steam from directly contacting the food, which will affect the cooking efficiency. After the fan 122 is started, the superheated steam in ...

Embodiment approach 3

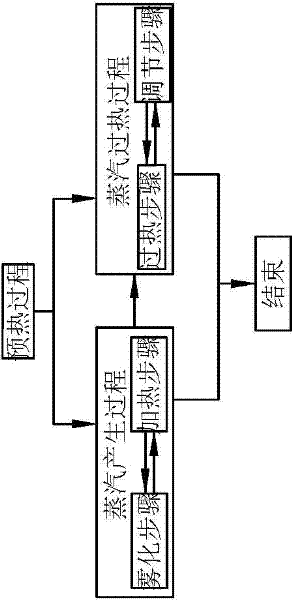

[0074] see Figure 5 The third embodiment of the method for controlling superheated steam generated by an electric steamer according to the present invention differs from the second embodiment in that: the steam generation process and the steam superheating process are cyclically and alternately performed. That is, after the preheating stage is over, firstly the steam superheating process generates heated steam for a period of time, then shuts down, enters the steam superheating process, shuts down, and then enters the steam generation process, and so alternately cycles until the cooking ends.

[0075]The steam generation process includes an atomization step and a heating step. The heating step works for a period of time t before entering the atomization step, and the atomization step and the heating step stop simultaneously. In this way, when the water mist is sprayed out, the temperature of the heating element 131 is low, which will cause the water mist to evaporate slowly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com