Automatic air discharging system of infusion device capable of preventing blood return

An anti-blood infusion set and automatic exhaust technology, applied in subcutaneous injection devices, devices introduced into the body, etc., can solve problems such as the inability to effectively control the position of the gas-liquid interface, the entry into the vein, and the lack of setting and exclusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

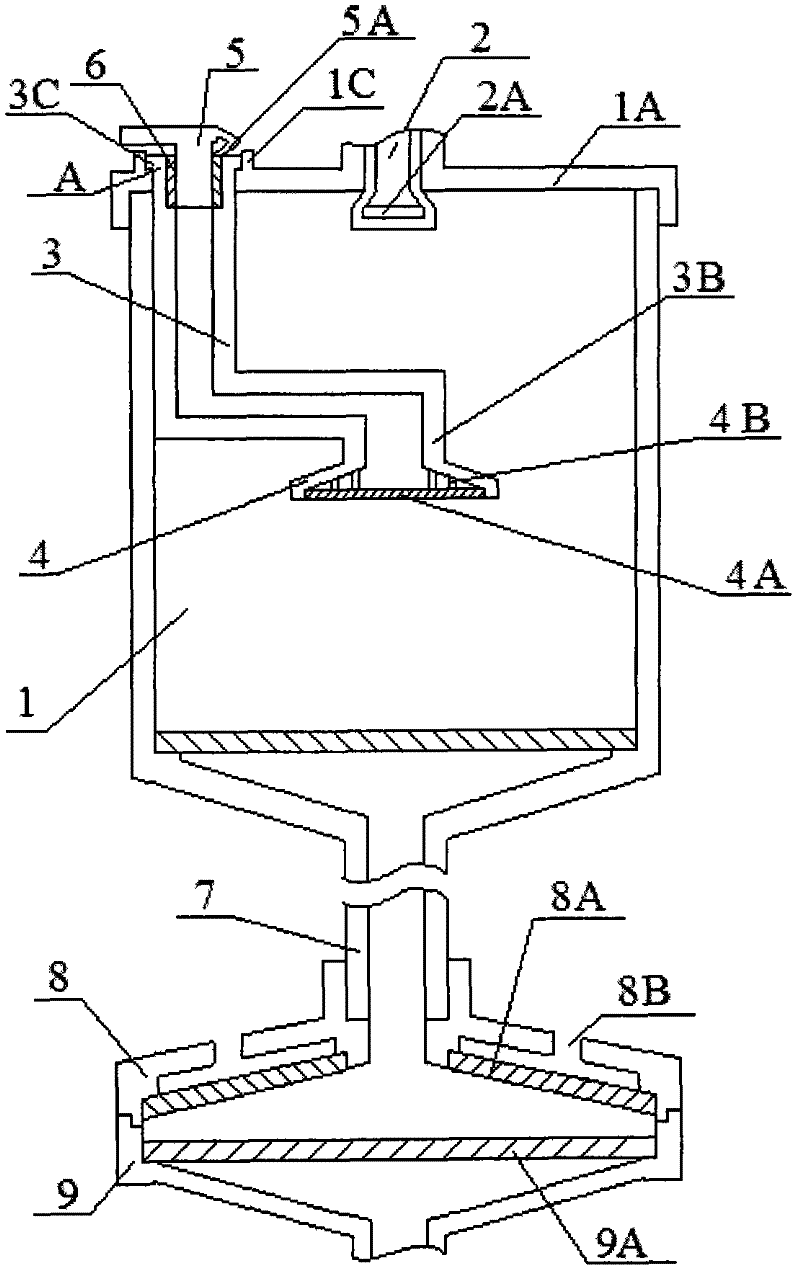

[0022] Such as figure 1 The shown automatic exhaust system is used for the anti-blood infusion set. The upper part of the dripping funnel 1 is provided with a dripping funnel cover 1A, and a nozzle 2 is connected to the neck of the dripping funnel cover 1A. The mouth 2A of the nozzle 2 is set on the dripping funnel. the upper end of the cavity. The first air filter 4 and the exhaust pipe 3 are all arranged in the dripping funnel cavity. Offer an opening on the dripping funnel cover 1A to connect the second end 3A of the exhaust pipe 3 . A sealing plug 5 is provided on the second end 3A of the exhaust pipe 3 . A sealing ring 6 is provided between the sealing plug 5 and the inner wall of the second end 3A of the exhaust pipe 3 , and a connecting piece 5A is also provided between the second end 3A of the exhaust pipe 3 and the sealing plug 5 . The exhaust pipe 3 sticks along the inner wall of the dripping funnel 1 and extends into the dripping funnel cavity, and when it reache...

Embodiment 2

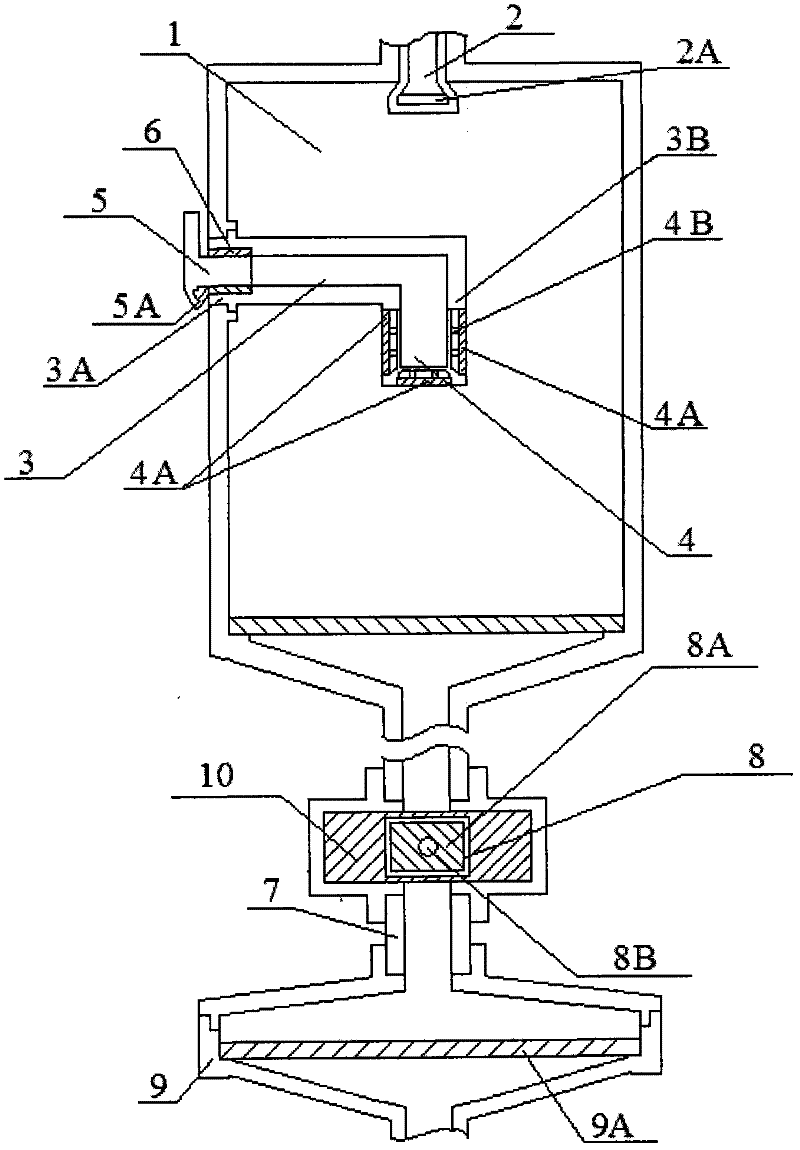

[0029] Such as figure 2 The shown automatic exhaust system is used in the anti-blood return infusion set. A nozzle 2 is connected to the neck at the upper end of the drip funnel 1, and the mouth 2A of the nozzle 2 is set at the upper end of the drip funnel chamber. The first air filter 4 and the exhaust pipe 3 are all arranged in the dripping funnel cavity. On the side wall of the dripping funnel 1, an opening is opened to connect the second end 3A of the exhaust pipe 3 at a position between 1 / 2 to 2 / 3 of the pipe height of the dripping funnel 1. A sealing plug 5 is attached to the second end 3A. A sealing ring 6 is provided between the sealing plug 5 and the inner wall of the second end 3A of the exhaust pipe 3 , and a connecting piece 5A is also provided between the second end 3A of the exhaust pipe 3 and the sealing plug 5 . Exhaust pipe 3 extends horizontally inward toward the central area of dropping funnel 1, and the first end 3B of exhaust pipe 3 opens downwards to...

Embodiment 3

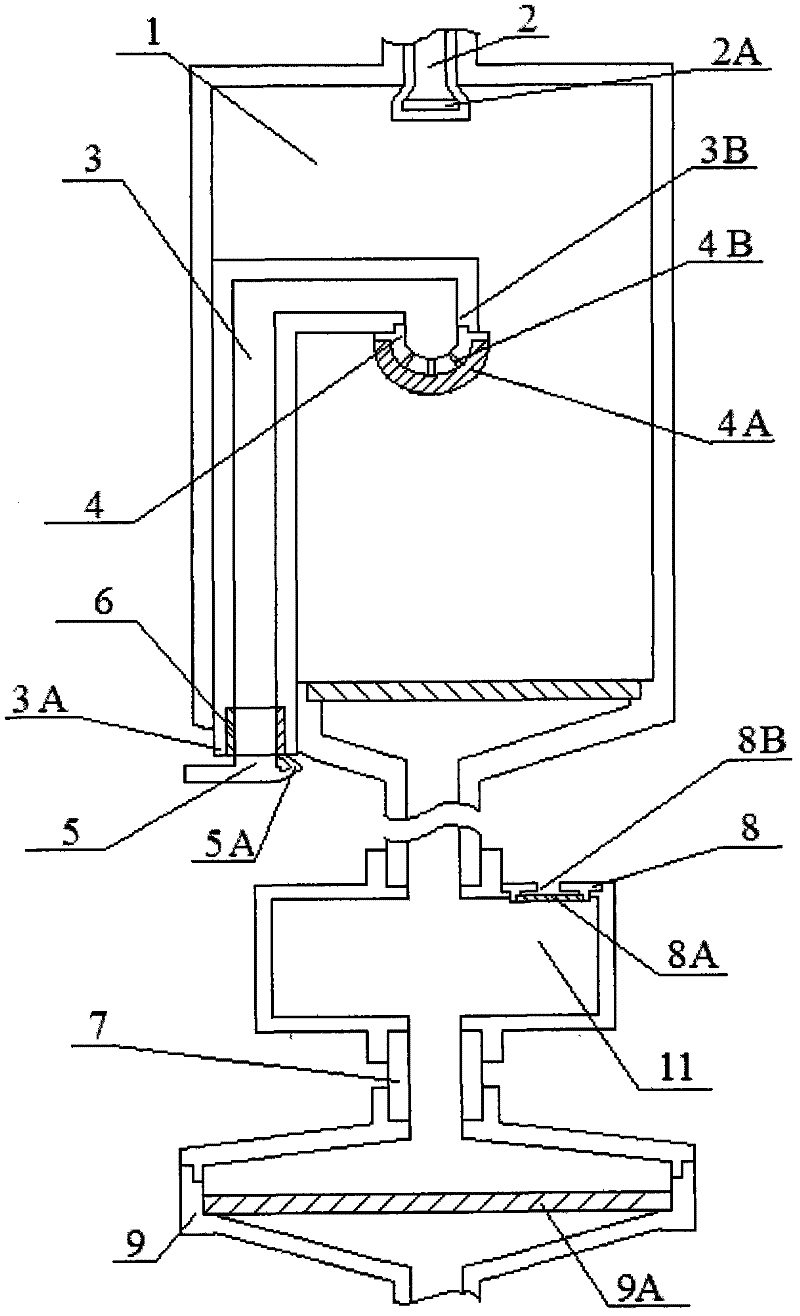

[0033] Such as image 3 The shown automatic exhaust system is used in the anti-blood return infusion set. A nozzle 2 is connected to the neck at the upper end of the drip funnel 1, and the mouth 2A of the nozzle 2 is set at the upper end of the drip funnel chamber. The first air filter 4 and the exhaust pipe 3 are all arranged in the dripping funnel cavity. Offer an opening on the bottom wall of the dripper holder 1B to connect the second end 3A of the exhaust pipe 3, connect a sealing plug 5 on the second end 3A of the exhaust pipe 3, between the sealing plug 5 and the inner wall of the exhaust pipe 3 A sealing ring 6 is arranged between them, and a connecting piece 5A is also arranged between the second end 3A of the exhaust pipe 3 and the sealing plug 5 . The exhaust pipe extends upwards towards the cavity of the dripping funnel, and turns horizontally toward the central area of the dripping funnel 1 when reaching between 1 / 2 and 2 / 3 of the pipe height of the dripping fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com