Dumper with discharge spray dust suppression device

A technology of dump truck and water mist, applied in the direction of injection device, liquid injection device, vehicles with inclined bearing motion, etc., can solve the problems of long unloading interval, affecting equipment operation, frequent starting and stopping, etc., to prevent hot jams. The effect of reducing the loss of dust, reducing the phenomenon of dust, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

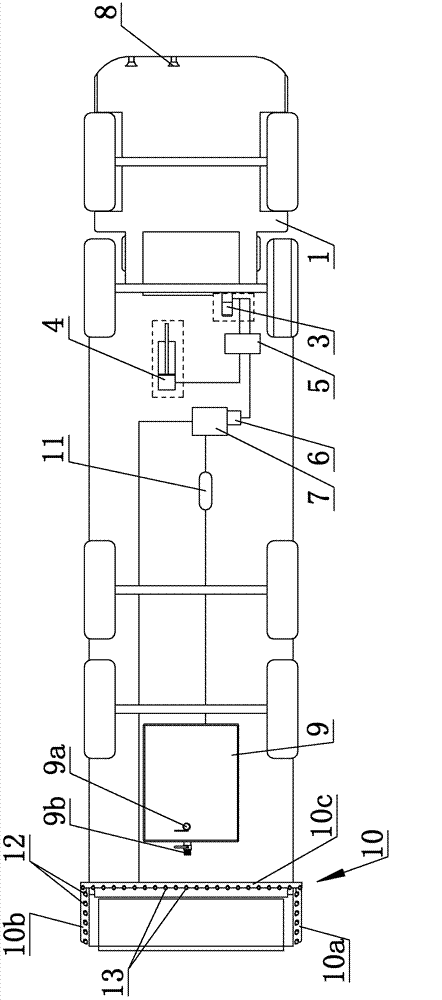

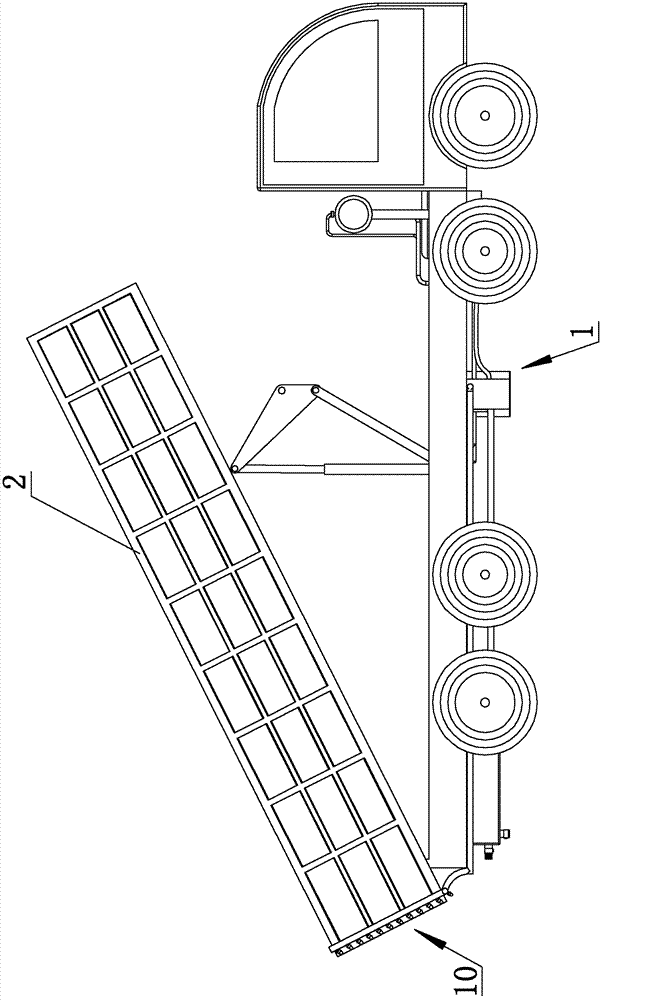

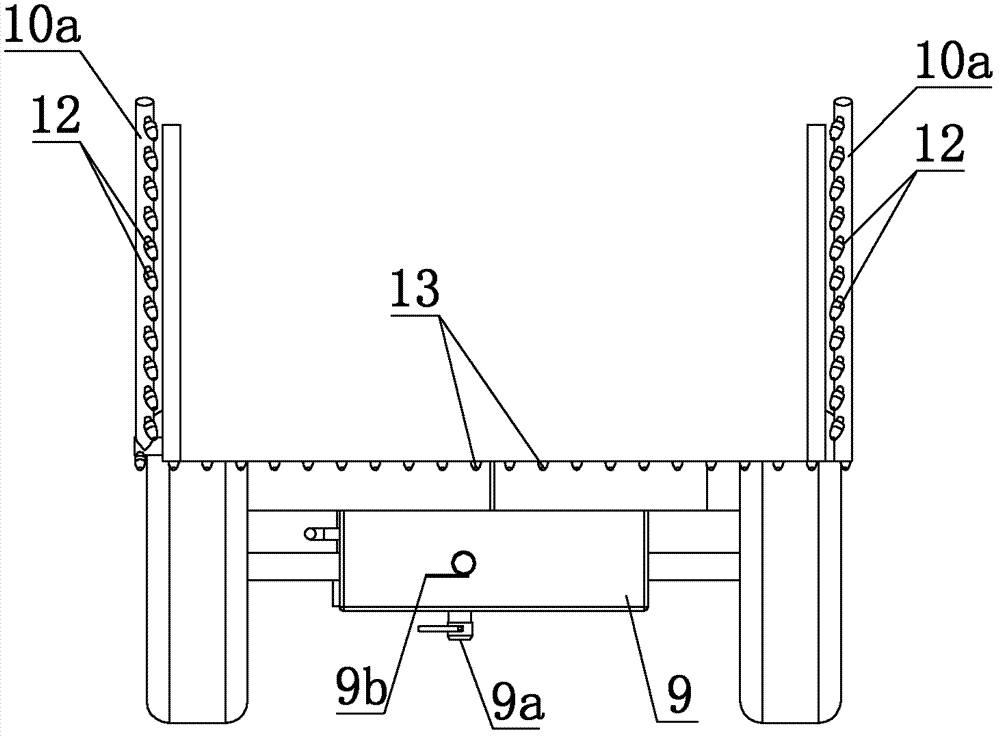

[0021] refer to Figure 1 to Figure 5 As shown, a dump truck with a dump water mist suppression device of the present invention comprises a car body 1, a compartment 2 is provided at the bottom of the car body 1, a power transmission box 3 is provided at the bottom of the car body 1, and the power transmission The tank 3 pipeline is connected with the dump arm assembly 4, and the pipeline between the power transmission box 3 and the dump arm assembly 4 is provided with an oil distributor 5, and the oil distributor 5 pipeline is connected with the hydraulic motor 6, The power output shaft of the hydraulic motor 6 is connected with the plunger pump 7; the circuit of the oil distributor 5 is connected with the hydraulic motor control button 8, and the hydraulic motor control button 8 is arranged in the cab of the car body; the water inlet pipe of the plunger pump 7 The water tank 9 is connected to the road, and a filter 11 is arranged on the pipeline between the plunger pump 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com